Researchers develop a novel approach to control drug release through complex 3D printed geometry.

Pills are something most of us use from time to time, and the design of pills hasn’t changed much for many decades: it’s just a bundle of the same chemicals pressed into a pill shape.

Once swallowed, the pill dissolves from the outside-in, releasing the chemical as it proceeds. Once in your gut, there’s no way to control the rate of chemical release.

While this approach definitely gets the drug into your system, it is not the most optimal approach. Consider that the surface area of the pill shrinks as the pill slowly dissolves. This means that the actual rate of drug release decreases over time. This may not be the optimal profile for releasing the drug into the patient’s system.

Many drugs are best deployed using a controlled profile. Perhaps a consistent release is required, or maybe it must slowly build up over time. Or decrease. Whatever the desired profile might be, there’s really no way to implement it with conventional pill designs.

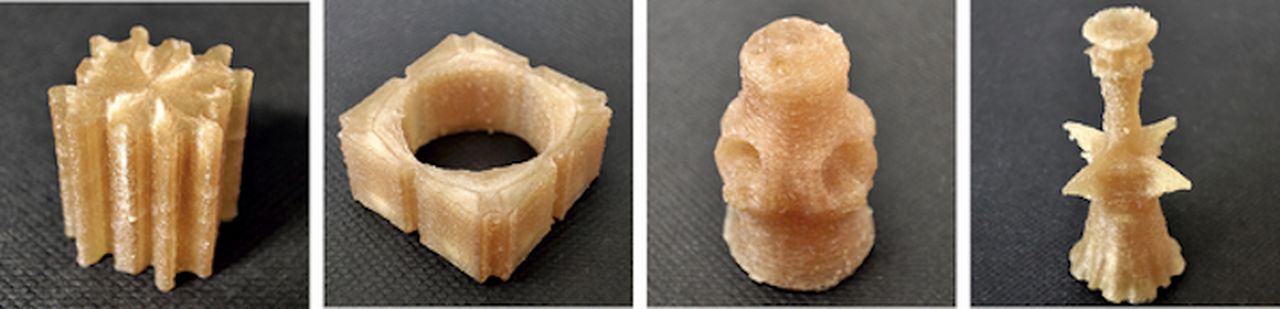

The new research uses topology optimization to determine unique geometries that can implement more complex drug release profiles. This is accomplished by managing the amount of surface area exposed while the pill shrinks.

The researchers developed simulations to generate unusual pill topologies that would be able to dissolve while releasing drugs at predictable rates. They verified their simulations by physically printing pill samples and observing the dissolving process with cameras. During this observation they were able to precisely measure the amount of drug released, thus verifying the simulation’s accuracy.

While many of the unusual pill geometries must be 3D printed, some cases allow more simple structures that could be extruded and thus be immediately useful for mass production.

This is a highly unusual approach that has great promise. It clearly works well, and for certain drugs that truly require unusual release profiles it could be ideal.

On the other hand, 3D printing pills could make the drugs more expensive. This would be financially infeasible for low-cost drugs, but perhaps could be justified with more expensive drugs — and make them more effective.

The researchers suggest that while the technique works for drug release, it could also be used in other industries. For example, releasing catalysts at a predictable rate in an industrial process, or keeping chemical additives at a consistent level in a tank are possible.

While this sounds tremendously interesting, I’m wondering how, exactly, I hope to swallow some of these unusual shapes.