Do pre-sliced 3D models make sense?

Pre-sliced 3D models are frequently found with newly-purchased desktop 3D printers. The idea is that the operator will want to perform an immediate test of their equipment to make sure it works properly, particularly after owner-assembly.

Manufacturers typically provide these GCODE files on a USB stick or through a download option. The models selected tend to be focused on either branding or benchmarking.

Some companies use the standard #3DBenchy object as a sample print, and typically cook the print parameters to print it as fast as possible. However, the operator can’t see the parameters used on the pre-sliced print, so it is sometimes very difficult to duplicate the performance.

Other times manufacturers include some kind of branded object that exhibits some notable features that demonstrate resolution, smoothness or other capabilities of the device.

This approach usually works reasonably well on FFF desktop 3D printers, so long as the operator loads in the correct filament to match the unseen print parameters: you can’t print in ABS material if the pre-sliced file assumes PLA, for example. However, in almost all cases there is an assumption that PLA is the intended material.

Recently we’ve been testing some resin 3D printers, which also come with pre-sliced print jobs. If it’s done for FFF devices, then why not for resin machines?

Our team got into a discussion about a particular pre-sliced file, and realized there’s a problem. The resin 3D printer manufacturer really has no idea which resin will be used to print the pre-sliced file.

In the FFF scenario the assumption of PLA is reasonable: most operators print in PLA, and variations in temperature requirements for different brands of PLA are quite slight.

That’s absolutely not the case for resin 3D prints. There isn’t a “PLA-like” resin standard for that type of 3D printer. Resins can have vastly different exposure times.

Remember that the manufacturer will know the light engine power for the specific 3D printer model, but they cannot know which resin is being used. Polymerization occurs when a resin receives a sufficient amount of energy from a light source. They know one side of the equation, but not the other.

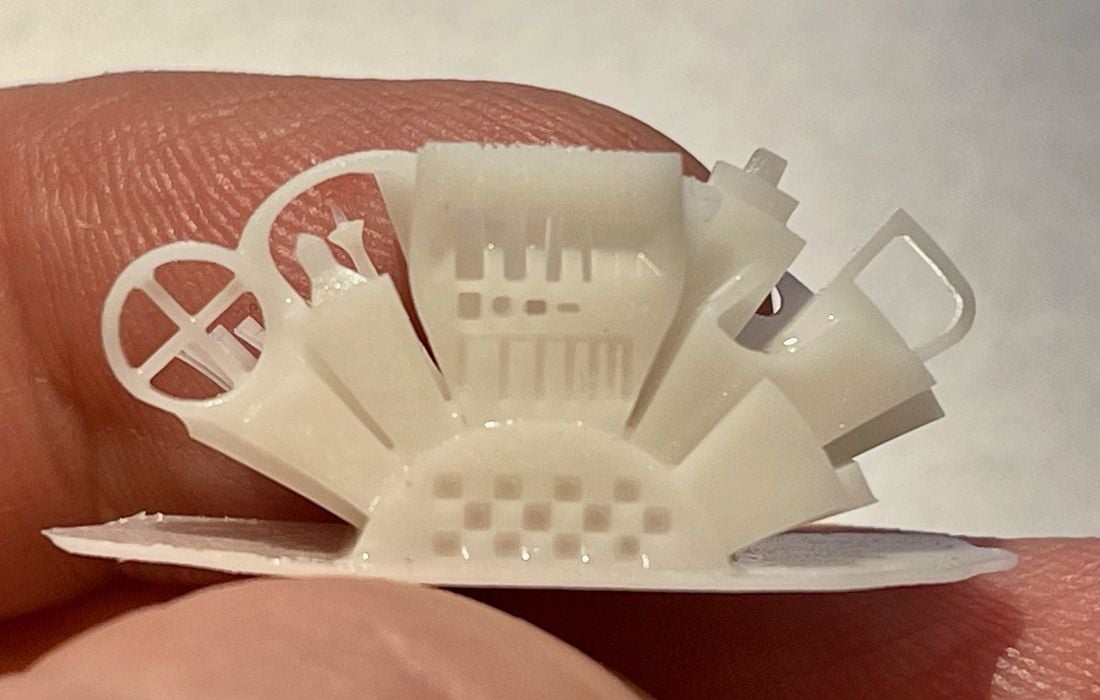

The observation that triggered our discussion was a pre-sliced resin job that seemed to be vastly overexposed. The resolution was poor due to overexposure blurring, and the model’s support structures would basically explode in a shatter when we removed them.

When we manually calibrated our resin for the printer, we realized our exposure times were substantially shorter than what had apparently been used on the pre-sliced job.

Why would the manufacturer overexpose the print so much? Wouldn’t they want to provide an optimized pre-sliced job, just like is done on FFF devices?

We realized the answer: they cannot do so.

Because they have no idea which resin will be used, they simply overexpose the print to make sure that it will print something successfully, regardless of how insensitive the unknown resin might be.

This might demonstrate that the printer works, but certainly does not show the true capabilities of the printer.

My thought is that pre-sliced jobs for resin 3D printers should be entirely avoided. They are not tuned for your device and really don’t provide any value.

The best approach for manufacturers should be to provide some means of calibrating the resin, and then follow up with a standard test 3D model that could be sliced with the calibrated parameters.

Not many resin 3D printer manufacturers seem to do this. One is Anycubic, that includes a useful “R.E.R.F” procedure to calibrate resin on their devices.

Until we have smarter resin 3D printers or some kind of standardized resins, we’re stuck with this manual approach.