PowerBelt3D is set to release a very low-cost belt 3D printer, the TinyBelt.

Belt 3D printers are of considerable interest because they offer two capabilities not present on other 3D printers: the ability to print very long objects, far longer than the device; and the ability to print a continuous stream of small objects without intervention.

So far there are only a few belt 3D printers on the market, along with a couple of open source designs, so there’s not much choice. The initial belt offerings were relatively expensive, being the BlackBelt machine and more recently a device from iFactory. Creality broke through price barriers with a lower cost device that proved quite popular.

But does this mean that those with smaller budgets won’t have the opportunity to use belt 3D printing tech? That could change with the introduction of the TinyBelt 3D printer from PowerBelt3D.

PowerBelt3D is a 3D print startup — apparently a one-person operation. The President is Ohio-based Adam Fasnacht. Fasnacht is a mechanical engineer that’s been developing and maintaining his own 3D printers for many years.

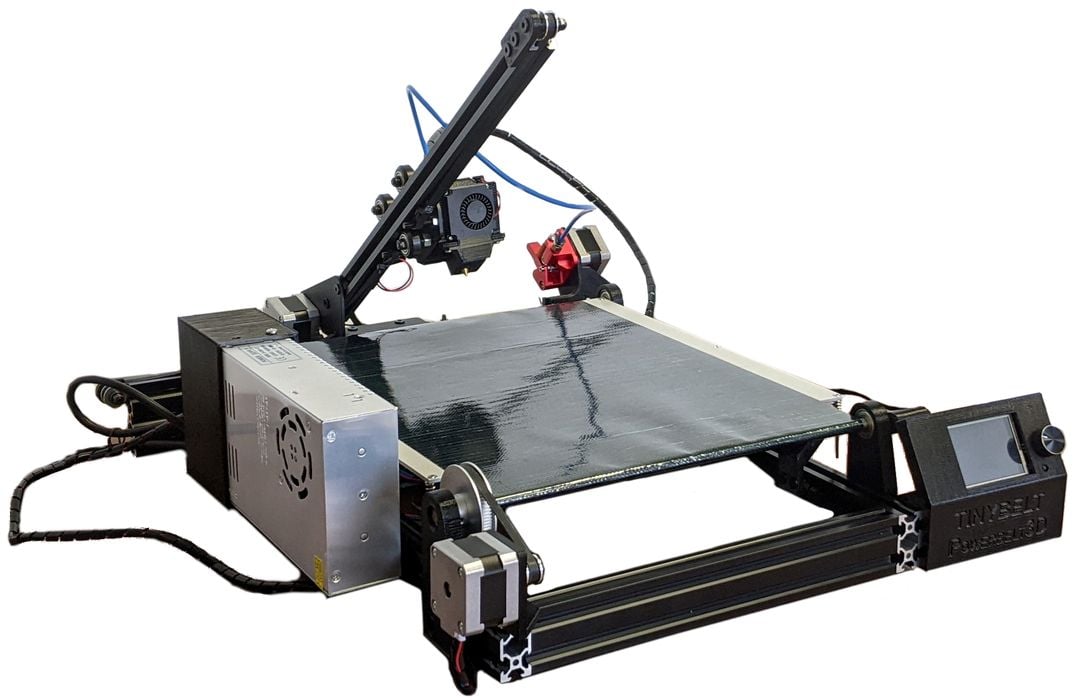

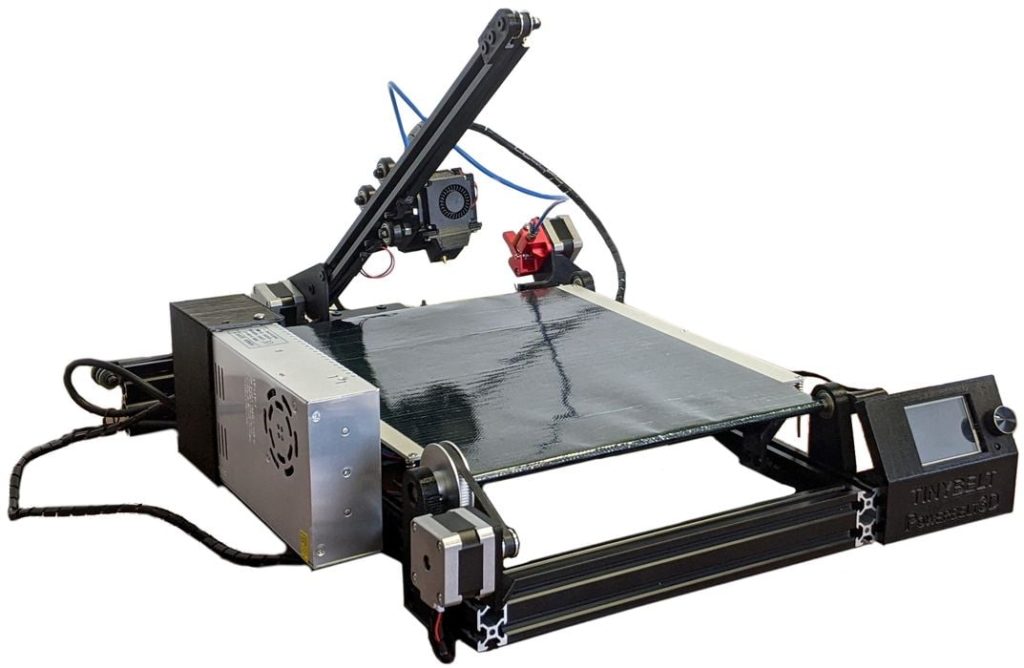

TinyBelt 3D Printer

The TinyBelt is exactly that: a belt 3D printer with a smaller size than some of its competitors. The design also seems to keep things quite basic, also helping lower the cost.

The basic specifications for the machine are:

- Build volume: 300 x 200 x infinity mm (it’s continuous, remember?)

- Dual-gear extruder

- Silent stepper motor drivers

- Handles PLA, PETG, ABS and TPU

- Machine size of 575 x 515 x 370 mm, far smaller than competing devices

But the most important statistic about the TinyBelt 3D printer is its price. For their soon-to-launch Kickstarter campaign they will charge only US$399 for the device. That’s 62% less than Creality’s CR-30 machine, which was the previously least expensive belt 3D printer available from a manufacturer.

But will you get a good printer at that price? That’s always the question when faced with surprisingly low-cost options, particularly if they are offered through a Kickstarter campaign.

PowerBelt3D sent us some images of sample prints, and they’re quite interesting to examine.

Here we see the classic Marvin 3D print. Notice the angle of each layer is not horizontal, as you would normally see on a typical 3D printer. Also the extrusion lines seem a bit coarse, but that could be due to the settings on this specific print job.

Here is a #3DBenchy print, a 3D model often used to calibrate printer settings. The print seems to be very well done, and again you can see the strange angles of the extrusion planes.

If you look at the images of the machine, there’s a couple of things to note.

First, there is no cooling zone on the belt. It appears that the entire belt is heated during printing. That’s great for printing, but at the point the print begins to roll off the belt, the heat could soften thinner prints and generate curls. I suspect it would be required to have some kind of accessory hardware to match up with the end of the belt and catch objects horizontally. Some other belt 3D printers have hot and cold zones under their belts, preventing this potential issue.

Another area I’m interested in is the extruder mount, which seems to be a cantilevered affair. Although made from rigid aluminum, it is possible there could be wobble on this strut if high-speed activity takes place. However, it’s possible this could be avoided with carefully tuned print settings.

Nevertheless, this could be a very attractive low-cost option for those seeking a belt 3D printing alternative

Via PowerBelt3D