Porsche announced they intend to offer 3D printed seats for certain models beginning in February.

The well-known automaker specializes in sports cars, and the seat is a critical component. Drivers of “normal” cars may not realize this, but sporty cars often have specially designed seats that keep the driver (and passenger) locked in position, even during extreme maneuvers.

At the same time, the seat must be comfy and attractive. Seat design is not a trivial matter.

Porsche has taken a big step forward by offering optional 3D printed seats on specific models of Boxster, Cayman, 911 and 718.

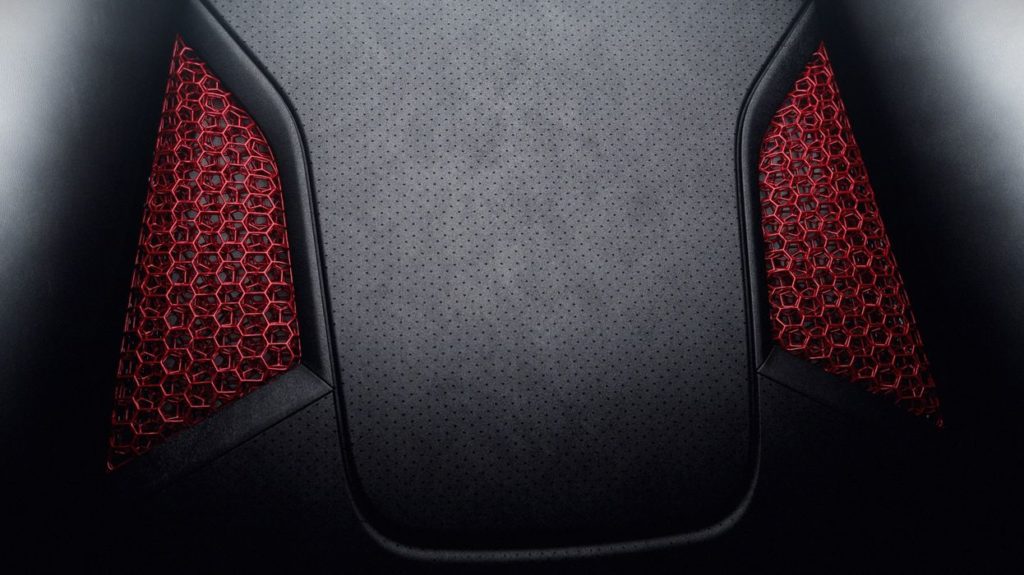

The entire seat is not 3D printed, but the “breathable comfort layer” is a 3D printed polyurethane structure. It’s placed on a polypropylene base and an outer skin.

While the new optional seat is definitely a stunner appearance-wise, how has its design leveraged 3D print technology?

One important benefit is that the seats are eight percent lighter than previous models. This is somewhat important in a vehicle that is all about speed and acceleration, where excess weight can slow the vehicle.

Secondly, the seats are designed in three levels of firmness. It appears Porsche has used an internal lattice structure to produce “comfort”, and by varying the configuration of the lattice they can develop the different levels of firmness.

Seats will be offered for the driver position, and only for certain models the passenger position as well.

Porsche test driver Lars Kern said:

“Seats adapted to individual drivers have been available for a long time in professional motorsport. Now Porsche also offers a road-approved customisation with different rigidity grades as standard. During the initial test drives I was impressed by the ergonomics – the slightly lower seat position and improved thigh support are similar to what you get from a seat in a racing car. The passive ventilation is impressive too.”

While this is an impressive development, I felt that Porsche could have pushed the technology a bit further. Then, I read this in their release:

“Porsche is planning another customisation for the medium term: 3D-printed bodyform full bucket seats adapted to the individual body contours of each customer.”

This could take Porsche drivers to almost racing level, with seats designed specifically for them.

However, the challenge in doing that would not necessarily be the 3D printing: instead it would be the method of collecting the information from the buyer. They’d have to develop some type of scanning system they could deploy to their local dealers, where part of the ordering process would be to capture the necessary seat geometry.

That could be an expensive proposition if done with scanning hardware. However, I suspect instead they’ll have a simpler system that categorizes the buyer’s shape within a set of specific seat geometries. This set of possible seats could then be extensively tested in advance, ensuring success when selected.

One issue may arise with this concept: car sharing. What if a driver allowed another person — perhaps their spouse — to drive the vehicle? Would they be unnaturally uncomfortable in the alien seat? Could this effect be a factor that deters buyers from selecting the feature?

Cars can be personalized to the body, but only one person’s body, and that conflicts with situations where more than one person drives the car. This is quite unlike 3D printed fashion, where the clothes are typically designed for and used solely by the individual.

Nevertheless, this is a very interesting step for Porsche, and it may prompt other automakers to explore additional uses of 3D print technology for personalization.

Via Porsche