Polymaker showed us some of their recent products, and it’s quite amazing what they’ve developed.

The China-based producer of high quality filament has been one of the leaders in the industry, producing not only well-regarded filament products, but also innovative combinations that frequently enable new applications.

We spoke with them at Formnext 2022, right underneath this gigantic spool of filament. It’s not actually filament, but is scaled perfectly from one of Polymaker’s actual spools. The design, made by Polymaker’s Luke Taylor, used construction materials as the “filament”, which was 19.5mm in diameter. The rest of the structure was simply scaled appropriately. Taylor explained that it was easy to move during set up and take down because “it rolls!”

While most 3D printer filament manufacturers these days focus on innovative materials, including Polymaker, Polymaker is also focusing on colors. They’ve long had an extensive set of colors, but now they’ve really reached what could be the ultimate set: 114 different colors of PLA.

To demonstrate these colors, they printed an ice cream cone of each material and displayed them on a huge table, as seen above. As one would expect, some visitors pinched cones, so extra security was required. Nevertheless, it would seem that if you want a specific PLA color, Polymaker likely has it.

Their “silk” filament options are brilliantly colored and can transform common prints into much more visible and attractive alternatives.

One of their latest materials is “nylon 612”, which is apparently a material similar to nylon 6 and nylon 12. In other words, it’s stronger than PA12, but absorbs far less moisture than PA6.

The company is also developing a new ESD-safe material that leverages carbon nanotubes to conduct static electricity, and another material that contains only 50% virgin material, with the remainder made from recycled sources. We’re told this filament is only be sold in black color.

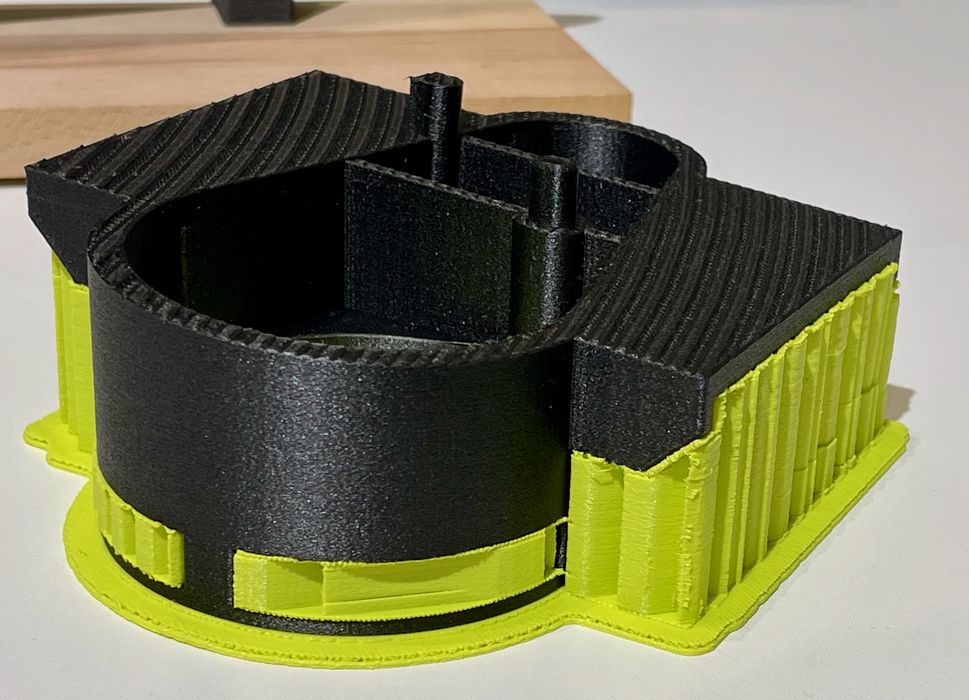

Another interesting material is their new breakaway support material, PolySupport for PA12. This material, designed to be used with their PA12-CF filament, provides a smooth interface, but breaks away very easily by hand. So long as you don’t have embedded support structures, this material could be one of the fastest to remove after printing.

One very interesting trivia note about Polysupport for PA12 is that it’s a green color. The reason for that unusual selection is that they’re comparing it to video “green screens”, which are removed during video development.

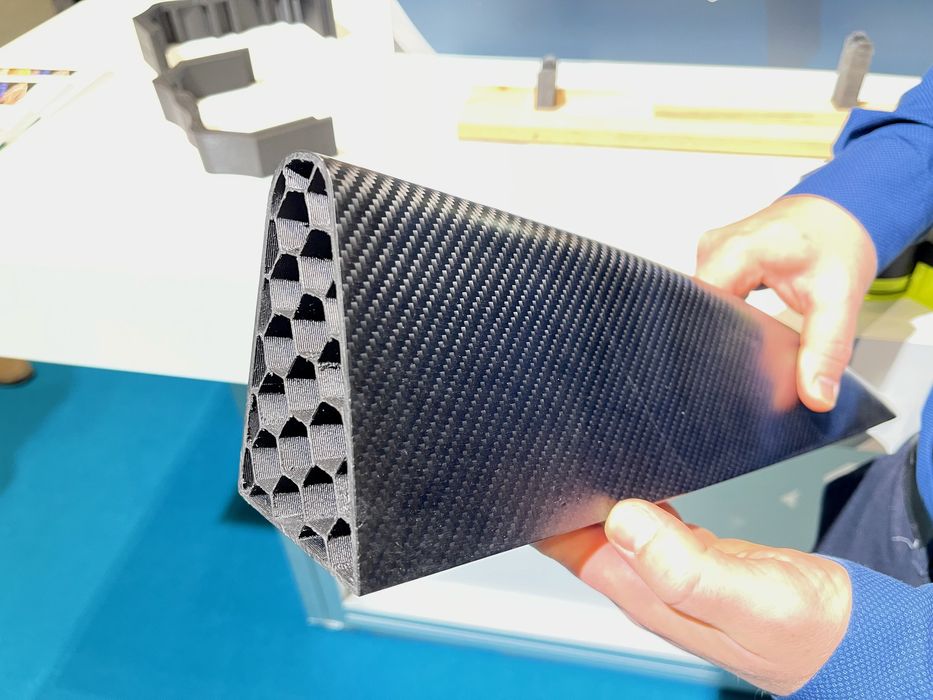

This wakeboard section is an interesting application of their CF material. As you can see, the interior portions of the wakeboard are 3D printed in lightweight form using their PA CF materials, but the outside is wrapped with standard carbon fiber sheets to provide a smooth surface for the wakeboard. It’s an interesting way to combine two different making methods.

Via Polymaker