This week Polymaker announced a partnership with AMESOS to developed what they call “FFF 2.0”, a high speed 3D printing process and associated 3D printer.

Polymaker is one of the leading manufacturers of high-quality 3D printer filament. Over the years they’ve introduced many innovative products to meet a variety of 3D printing requirements.

Most recently they have worked closely with industry to provide filaments suitable for production use in multiple applications.

Now they’re taking an even bigger step by partnering with AMESOS.

AMESOS is a spinoff of Singapore-based Akribis Systems. Akribis Systems produces advanced motors and motion control systems, and the production of a 3D printer using them seems like an appropriate step. The name, “AMESOS” stands for “Advanced Manufacturing Engineering Solutions”, and that certainly indicates their goal. According to Polymaker, this group has been working on 3D printing for at least five years, even though they have not released any products to the market.

Polymaker said:

“The deep technical capabilities in motor design and motion control from Akribis allowed the team to design 3D printing systems in ways that are very different from the status-quo.”

This sounds quite intriguing. What could make their system different?

It seems the difference is print speed. It’s well-known that one of the primary barriers to more widespread adoption of 3D print technology is the delay in producing objects. Today, for example, I launched a print job that would take over twelve hours for a single, not unreasonably-sized part.

That’s far too long.

It’s excessive when you consider how a business could use typical 3D printers: revenue is made only when parts are produced. If the machine can only produce a few parts per week, then it isn’t that valuable.

But what if the machine could 3D print parts far faster? The same single machine could produce more parts — and consequently more revenue — per week, and possibly enable many more companies to financially justify the technology.

But as most in the industry know, speeding up printing action is only happening when there is a precise combination of hardware, software, print parameters and material chemistry. That seems to have been discovered by AMESOS. AMESOS Co-founder Tommy Huang explained:

“We started by trying to solve the problem alone. But very soon we realized we are only part of the solution and desperately need many other areas of expertise.”

This explains the nature of the partnership: AMESOS provides the hardware and software, while Polymaker provides the material chemistry expertise. Together, they hope to develop an ultra-fast 3D printing process, FFF 2.0.

Their approach is a bit different from most 3D printer development projects. Instead of starting with the hardware, they are first defining the process itself, which no doubt will include print speed. Then they work backwards to engineer the components, software and materials to match.

The two companies are also working with Helio Additive, a company co-founded by Polymaker that has software to simulate the physics of extrusion. This technology is to assist in the development of the 3D printing process.

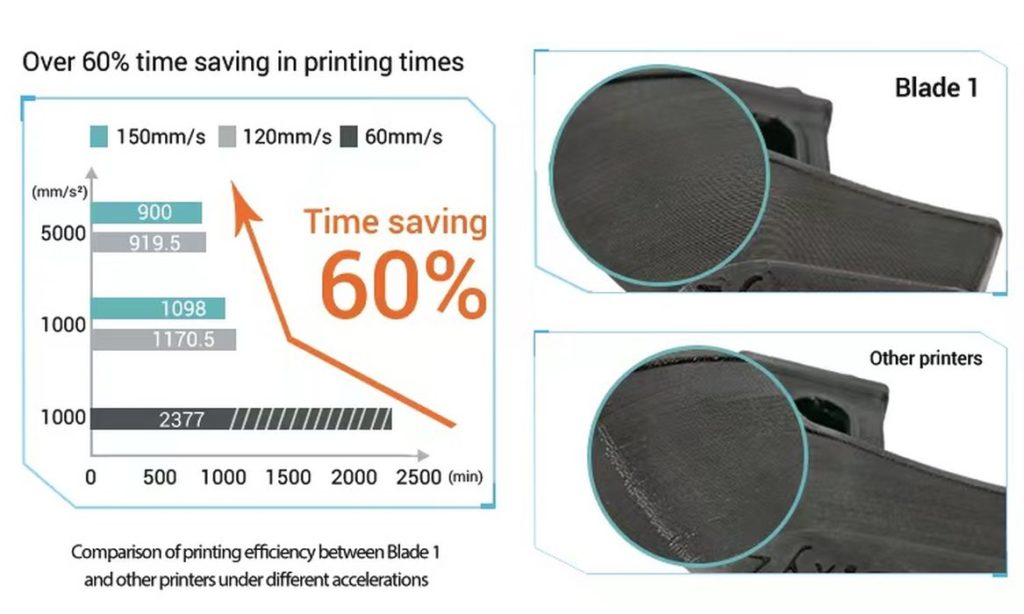

AMESOS reports their “Blade 1” prototype equipment has already been able to reduce print times by 60%. This translates to print speeds of 150mm/s, which is indeed faster than most devices that typically operate in the 40-80mm/s range.

It’s not all about speed, however. It’s speed AND quality. The companies are testing the parts produced at speed, and hope to match the quality and strength of parts produced at conventional speeds.

As of this writing, there are no 3D printers from the group on the market. However, they are “currently working on a multi-year technical roadmap”, which certainly will have releases of this technology mapped.

There’s always room for higher speed 3D printing, and I’m excited to see what AMESOS and Polymaker come up with in this venture.

Via Polymaker and AMESOS