Charles R. Goulding and Ryan Donley examine how 3D printing could be used in pickleball.

The Fastest Growing Sport in America – Pickleball

Pickleball is a game that combines tennis, ping pong, and some elements of racquetball into one game. The sport has mainly been synonymous with early youth P.E. classes but lately has gained popularity as a niche sport where nearly 3 million players are active in the U.S. today. Pickleball is also very popular in retirement communities.

Pickleball got its start in 1965 in Seattle, Washington and is credited to the Pritchard family where, from their home backyard, the sport grew exponentially year after year and is still growing to this day. Pickleball has grown quickly due to it having the ability to be played both indoors and outdoors. Dedicated courts for pickleball have been popping up lately whereas several years ago this would have been highly uncommon. Today there is not enough room on tennis courts, indoor gyms and the like to be shared with pickleball and dedicated courts are being constructed as the need grows.

3D Printing Rackets

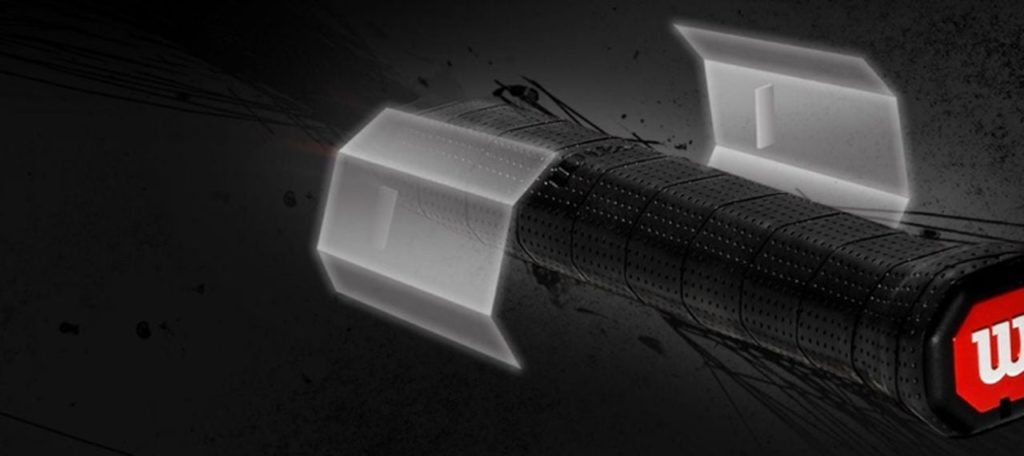

At the forefront of 3D printing in racket-based sports is Wilson Sporting Goods, the premier sporting goods company for tennis, pickleball, racquetball, and several other sports. Wilson has been experimenting with 3D printing methods for providing customizable, weight-balanced handles for rackets. Developments in 3D printing for Wilson have resulted in streamlined production where players can receive handles in as little as 72-hours compared to a typical 2 week wait time.

The handles are optimized for player utility as the handles are better for aerodynamics and have improved internal structures that are more durable and provide better weight balancing.

Wilson has also partnered with Azul 3D to create new 3D printed pickleball paddles and is disrupting the way that the game is played with two new designs – the Custom Core Paddle and the Quiet Paddle. The Quiet Paddles significantly reduces the sound from ball hits and the Custom Core Paddle is completely customized to fit a player’s style. The 3D lattice structure is more robust and provides less shock when striking a ball and will assist a player who may experience long-term hand and wrist issues from paddle use.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

With Pickleball’s rise in popularity and premier sporting good provider Wilson’s serious investment in the sport, it will continue to grow and retain its current player base. Pickleball’s playerbase and market share are continuing to grow year after year as well, the fastest growing sport in America today is seeing participation numbers gradually increase since 2015.