Photocentric is definitely moving into the large-format 3D print space.

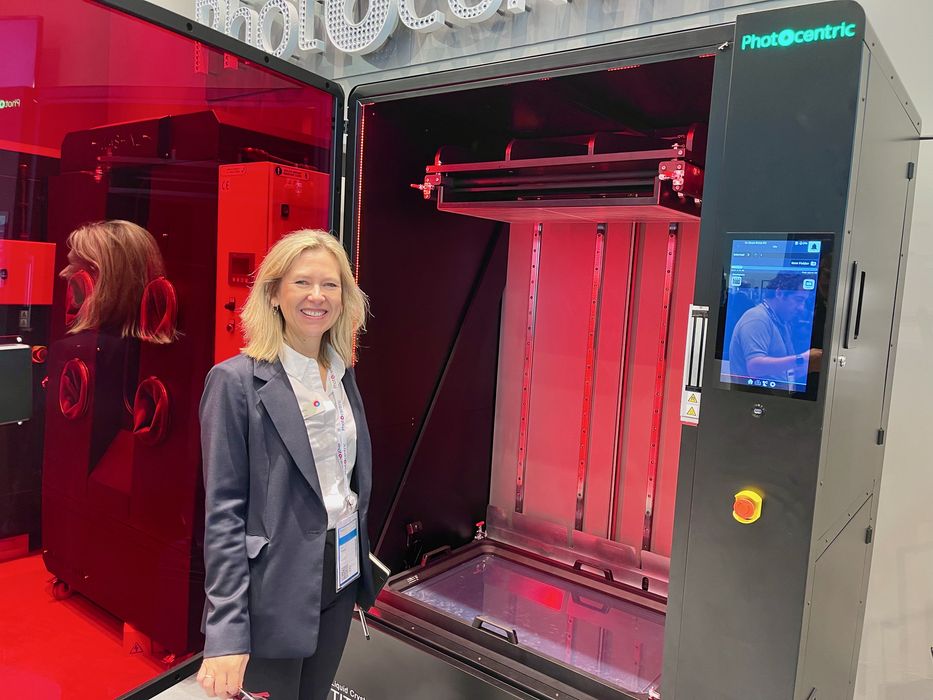

We were able to take a close look at the company’s flagship device, the long-awaited LC Titan. It’s an enormous resin 3D printer, perhaps the largest one we’ve ever seen. At top you can see an image of the machine with Photocentric’s Sally Tipping as the banana. It’s a huge machine.

The Titan’s build volume is an astonishing 695 x 385 x 1200 mm. This is over a meter tall, enabling the production of very large high resolution objects.

But does the Titan compromise on print quality? Many resin 3D printers have increasingly worse resolution as build volume increases. In this case the Titan manages to maintain a 0.091mm resolution, which is outstanding for parts of this size.

Large format 3D printers typically have an issue with print durations, so many larger systems have features that will speed up operations. Does the Titan do so as well?

They say that at a 0.350mm layer size, they can print up to 86mm/hr, or a volumetric rate of 24 liters per hour! For a 1200mm tall print, this suggests it could be complete the job in only 14 hours. That’s quite incredible — I can recall seeing large format devices take literally days or weeks to build something that big, and the Titan does so in high resolution.

The Titan would be ideal for producing sculptures, artwork and even furniture. What’s interesting to me is that the combination of high resolution and large size just might enable all manner of interesting industrial parts. Normally larger parts have more simplistic designs, but here we might have something comparable to the metal 3D printers that produce intricately designed rocket engines. This same approach could be done in polymers with the Titan, although not for rocket engines.

But wait, if you print large resin objects, don’t you have to wash and cure them just like regularly-sized prints? Yes, you do, and Photocentric has also made what has to be the largest wash and cure stations I’ve ever seen.

I asked Tipping about the cost of large prints, which can be considerable on other systems. She explained that the cost of Photocentric’s resins are quite low: their hard material for the Titan is only US$40/kg, far less than the US$200/kg charged by some other manufacturers. Their general daylight resin is even less expensive at US$23/kg, and their most expensive is a high temperature flame resistance material at a “whopping” US$90/kg.

These price points are not unsurprising, as Photocentric is one of the very few actual manufacturers of photopolymer resin. The get a good deal from themselves, clearly.

Speaking of resins, Photocentric recently introduced a new clear resin, and above you can see a sample of this material. It’s absolutely clear, with no yellowing as far as we could see.

With these low-cost resins, it’s very likely we’ll see some new companies emerge with the goal of producing unusual 3D printed furniture items.

Via Photocentric