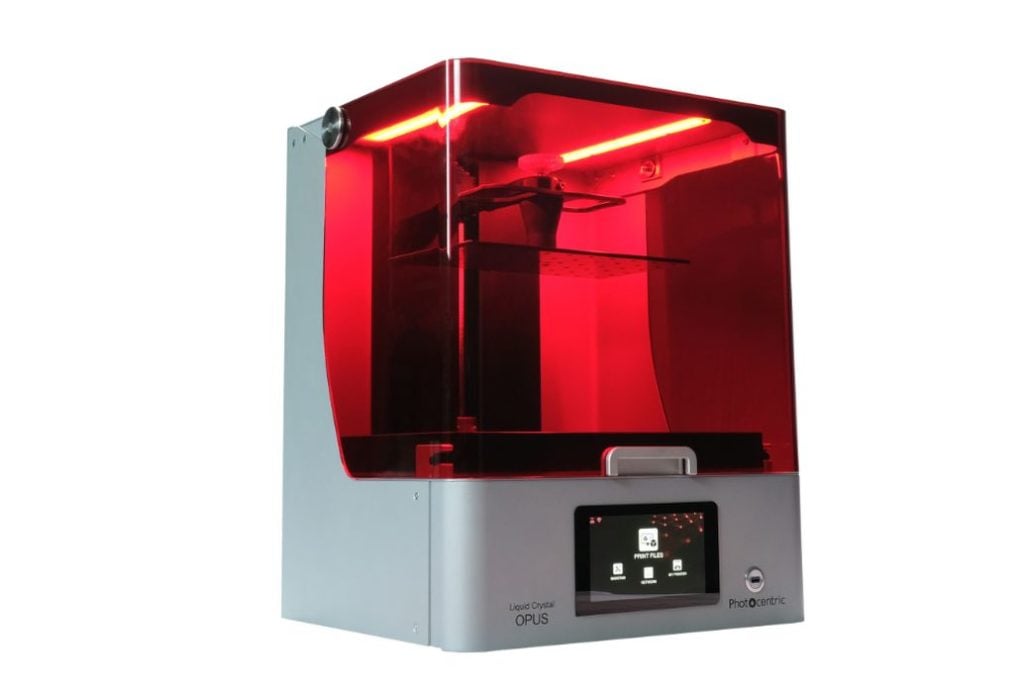

Photocentric has launched a new desktop resin 3D printer, the LC Opus.

The machine is the ninth 3D printer made by the company, which originated as a manufacturer of photopolymer resins, but later branched into producing their own 3D printer equipment in an effort to promote resins. However, they quickly found the business of 3D printer manufacturing to be quite profitable and have continued adding new models to this day.

That brings us to the LC Opus, their latest machine. It’s a bit of a departure from their previous equipment, which tended to be large-scale. Their LC Maximus offers a massive build volume of 893 x 510 x 700 mm, suitable for production. On the opposite end is the new LC Opus, which has a build volume of “only” 310 x 174 x 220 mm.

I say “only” with reference to its comparison with the LC Maximus; compared to most competing desktop resin equipment, the LC Opus is still quite massive.

Why the switch in machine format by Photocentric?

I suspect it has to do with the intended usage for the new LC Opus: dental and engineering. Photocentric’s material goes to quite some lengths to explain how the device can be beneficial to those applications. I don’t doubt that, particularly when you look at the company’s extensive list of functional resins.

The LC Opus uses an LCD process for solidifying photopolymer resin, as opposed to the laser and DLP processes seen in other equipment. They’re using a custom-designed 14” 4K monochrome LCD panel as the light engine in the LC Opus. This light engine’s wavelength is 410nm, in the UV range, making the machine compatible with many third party resins in addition to Photocentric’s own products.

Print speed is impressive due to the monochrome light engine. The specifications say the LC Opus can 3D print objects at up to 18mm in height per hour, and cure 0.05mm layers in about 2 seconds.

They’re able to produce high quality results with this configuration. The company explains they can achieve:

“XY resolution of 81µm provides scanned data accuracy of ≥95% at <100µm and ≥70% at <50 µm”

One question that always must be asked of resin 3D printer manufacturers is the method of peeling fresh layers off the resin tank. Photocentric uses a patented “Vat-Lift” process that “ensures reliability over large surface areas”. This is quite important, because the typical “lift the print” process might be compromised on a large print area such as used in the LC Opus.

They say this, combined with the tank design and materials used, makes for a very long life for the tank.

There’s three other interesting aspects of the LC Opus.

First, they’ve designed the machine to be extremely quiet. They have specialized fans for LCD panel cooling that are “ultra quiet”, and they use specialized stepper drivers that make operation mostly silent. This should make the device more office-friendly than some other devices. Longer jobs that run on this larger-scale desktop device would produce less noise pollution for those nearby.

The second interesting design feature is the longevity of the device. Photocentric has made the exterior case and other components potentially exposed to resin spills more chemically resistant. Spills are an inevitable occurrence with resin 3D printing, and it’s good to see they’ve taken this into account.

Finally, the LC Opus apparently requires no calibration. The resin tanks and motion system are designed to be “interchangeable without the need to re-calibrate”. That’s an important step, as it makes the machine more friendly for dental technicians or engineers producing prototypes. Photocentric’s easy-to-use STUDIO software should combine with the hardware to produce a very simple path to achieving great results.

The LC Opus seems to be a very intriguing device, and apparently Photocentric has received the most pre-orders for any machine produced by the company.

They’re expecting to ship units starting this month.

Via Photocentric