Researchers have developed a method for 3D printing flower jellies.

I know exactly what you are thinking right now: “What the heck is a flower jelly?”.

Flower Jellies

To be frank, I didn’t know either, but it turns out flower jellies are a thing in certain countries. There seems to be two kinds of flower jellies. One is an actual food item, a jelly made from different types of flowers for which there are many recipes. The other type, which is the focus of this discussion, is an edible dessert made from jelly and flower-like structures.

It seems that dessert artists will painstakingly create these flower jellies by injecting a differently-colored jelly into a clear jelly.

As with most artistic platforms, these flower jellies can get quite complex in design.

Now, researchers at the University of Tokyo have developed hardware and software that is capable of 3D printing flower jellies using a parametric slit injection 3D printing scheme.

3D Printed Flower Jellies

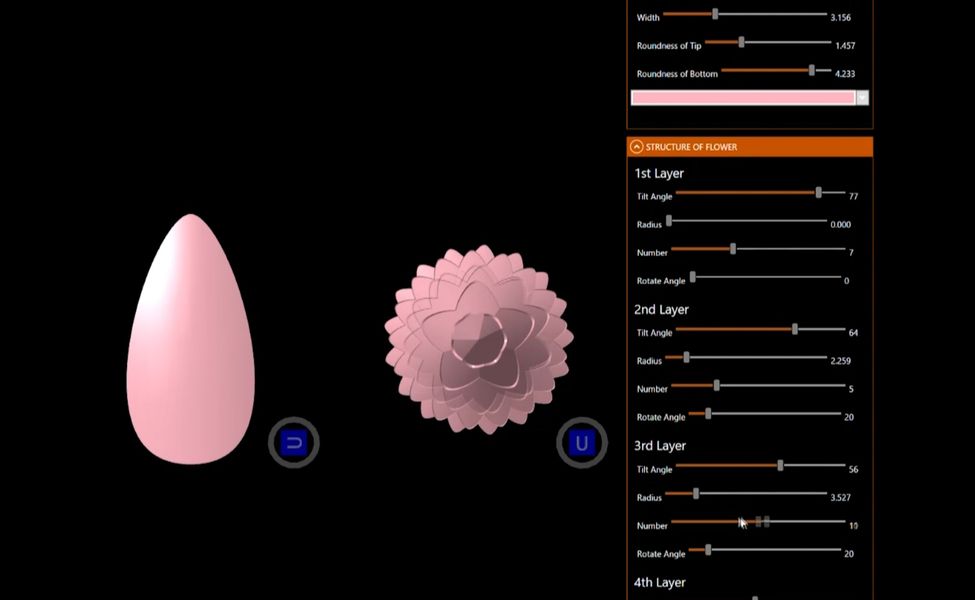

The process begins with a flower design that makes heavy use of parametric generation. A designer can tweak a number of slider bars to generate a unique flower design, which is essentially a collection of petals.

The software then generates GCODE to 3D print this specific design using a slit injection approach.

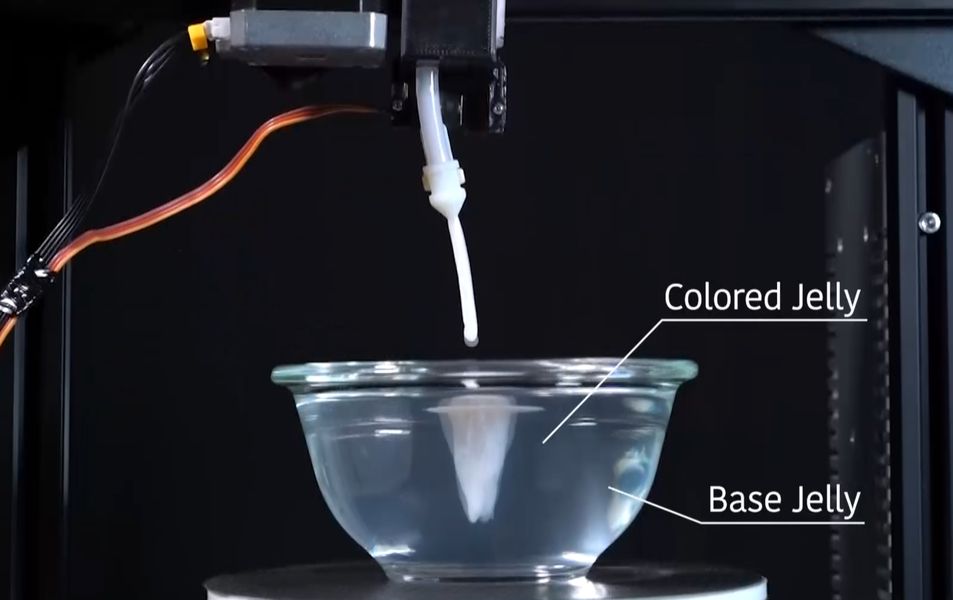

But what is “slit injection”? As you can see in this video, the 3D printer has a thin blade instead of the traditional nozzle. The blade slices into the clear base jelly at a specific angle, and when withdrawing it injects the colored jelly into the slit. The slit then closes around the new jelly, forming a thin, petal-like object.

In short order you end up with a flower jelly, and the designs shown by the researchers are quite varied in design, demonstrating the flexibility of the system.

Other Uses For Slit Injection 3D Printing

While flower jellies might not be a particularly popular use case, I’m wondering whether slit injection 3D printing could be adapted for other materials and used in a more general fashion.

I can see several possibilities:

If the “colored jelly” was instead an epoxy, it would harden into the shape. The clear jelly could be washed away to reveal the finished object. It might be useful to 3D print silicone objects in this way.

Another possibility might be to use a photopolymer jelly. After rapid slit injection, the clear jelly would hold the geometry of the object while it undergoes curing. Then the clear jelly can be washed away.

Composite materials might be used in slit injection 3D printing. Imagine if the colored jelly was in fact a mix of ceramic, polymer or metal powder and binder. The resulting object could then be heated to completely solidify it. This might be a new way to produce metal objects.

If there’s one thing I know, it’s that inventive people will do their best to leverage any technology to succeed in new applications. I suspect slit injection 3D printing might become an interesting option if they do.

Via ACM