It’s the end of the year, and I wondered which stories gathered the most views by Fabbaloo readers.

To determine the results, I fired up our analytics engine and went through our stats month by month all through 2021 to see which story was the most popular of each month. These are the results, barring some incredible burst of reading activity today, which is highly unlikely.

January: You May Soon Upgrade Your 3D Printer To Not Require Support

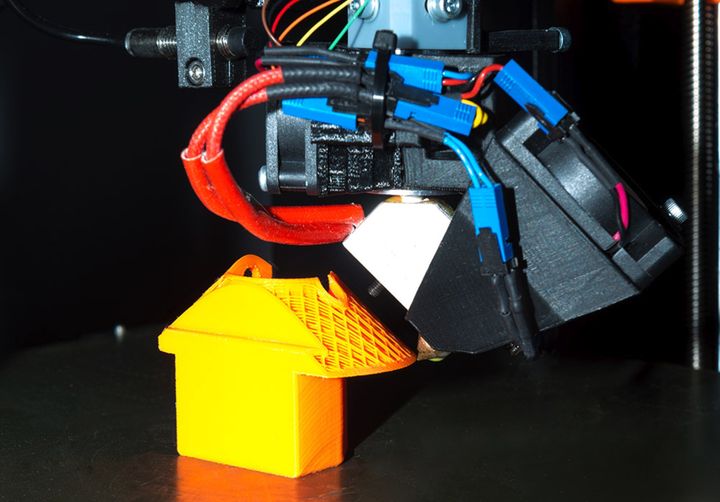

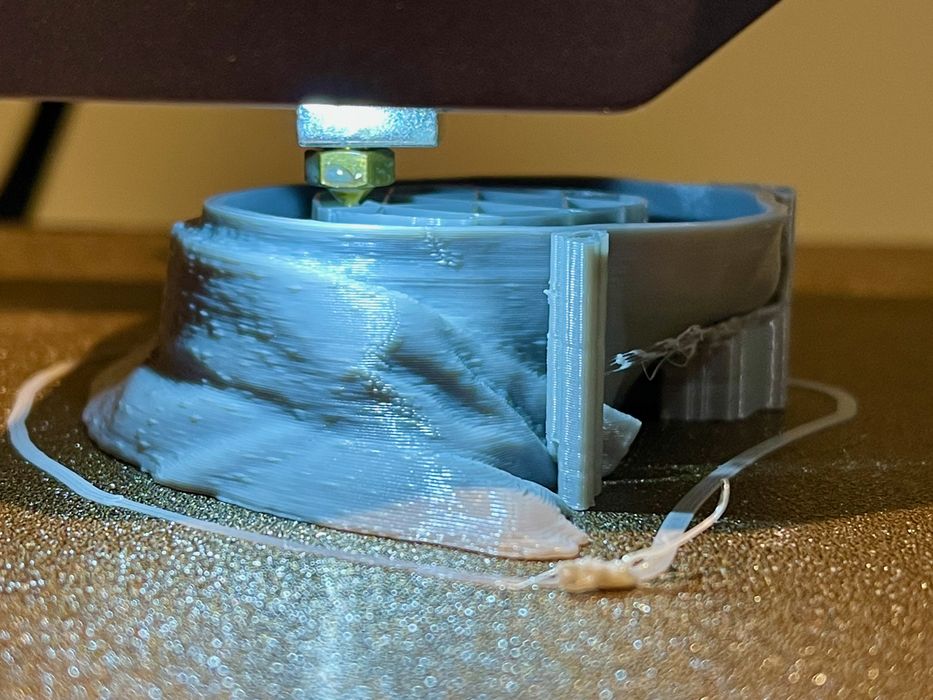

This story describes research undertaken by folks at the Zurich University of Applied Sciences who have developed a method of FFF 3D printing that requires no, or at least very minimal, support structures.

Their idea is to tilt the nozzle to 45 degrees, similar to what’s done with belt 3D printers, and build the object from the inside out.

Their system, called “RotBot”, has not yet seen commercialization, but I have to be sure that they are working with some 3D printer manufacturing partner to do so. This is something to look for in 2022.

February: Software For Self-Built 3D Scanners?

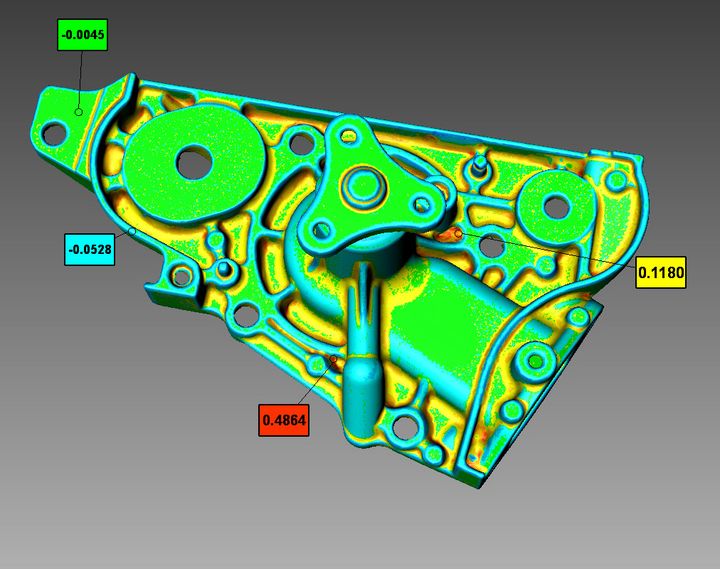

In February Vancouver-based Polyga released FlexScan, a software tool that implements 3D scanning functions. The idea is that you would build the hardware part of a 3D scanner on your own, then use FlexScan to drive it.

FlexScan appears to be a very powerful software tool that would rank with the top commercial software equivalents from actual scanner manufacturers. As it’s available by non-commercial license for only US$500, it could be an attractive option for those looking for an inexpensive 3D scanning alternative.

March: The Economist Tackles 3D Printed Crime

The venerable “The Economist” actually published a story on 3D printing, and one that actually made sense. Forgive my sarcasm, but coverage of 3D printing in mass media tends to focus on the spectacular and speculative aspects. This story rung true and discussed a number of issues for which I provided reaction from the 3D print world’s point of view.

April: Wall-Mounted 3D Printers?

Early 2021 was the belt 3D printing craze, with a couple of inexpensive models being released and used by the public. There’s one thing about belt 3D printers, though: they tend to take up a lot of desk space with their larger footprint and rather long space required to accommodate longer prints. There’s also a need for a catch bucket as objects stream off the belt.

The story related how someone managed to mount Creality CR-30 belt printers vertically on a wall, which takes up far less space. That’s a fabulous idea.

May: What Is Klipper, And Should You Use It?

Klipper is a third party firmware software package that is used to control many types of desktop 3D printers. It’s typically used only by hardcore DIY operators, as an alternative to the more common Marlin package.

The big deal with Klipper is that it allows more capacity to control the stepper motors on a 3D printer, and thus opens up the possibility of faster 3D print speeds.

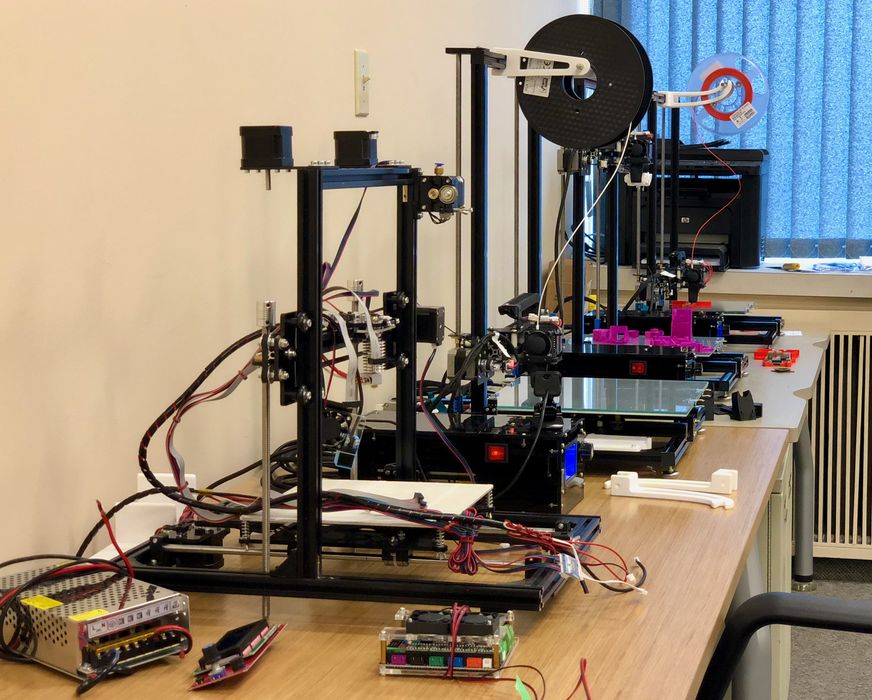

June: Complementary 3D Printers Is The Only Way To Go

This opinion piece from me describes the philosophy of having multiple — and DIFFERENT — 3D printers on hand. I said:

“I believe the answer is complementary machines. This is a concept where instead of having a single choice of 3D printer, you have two or more on hand. The idea is to have each machine type cover off a certain envelope of requirements, in hope of providing a wide variety of functionality.”

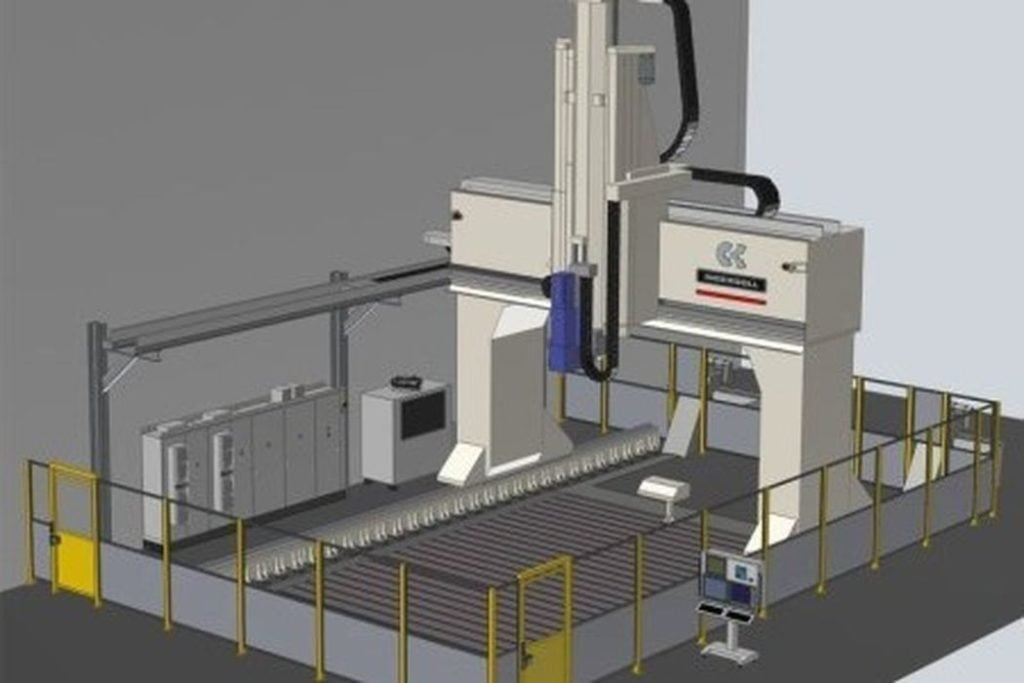

July: US Army To Build World’s Largest Metal 3D Printer

A report in July indicated that the US Army has launched a project to build what apparently would be the largest metal 3D printer ever. They intend on 3D printing hulls for a variety of advanced ground vehicles.

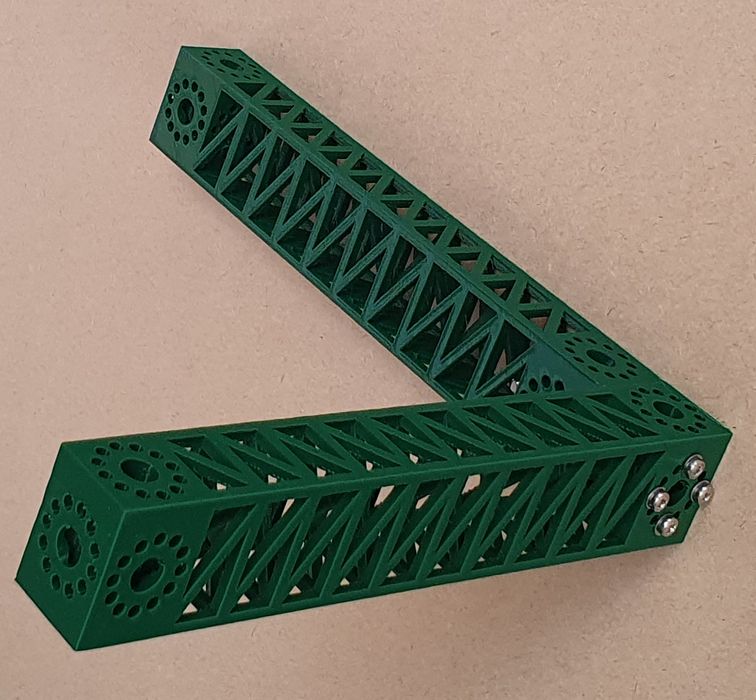

August: PLA Stronger Than Steel? New Script Generates 3D Printable Beams

The folks at RepRap Ltd. developed a Python script to automatically generate 3D models of strong beams using a minimal amount of material.

The script is freely available on GitHub, and can be used and modified for your own use.

September: Seven 3D Printer Features That Should Be Standard

I see a lot of 3D printers, and almost always there’s an interesting feature or two on them that I think should be a default for all machines. In this story I list the ones that really should be industry standards.

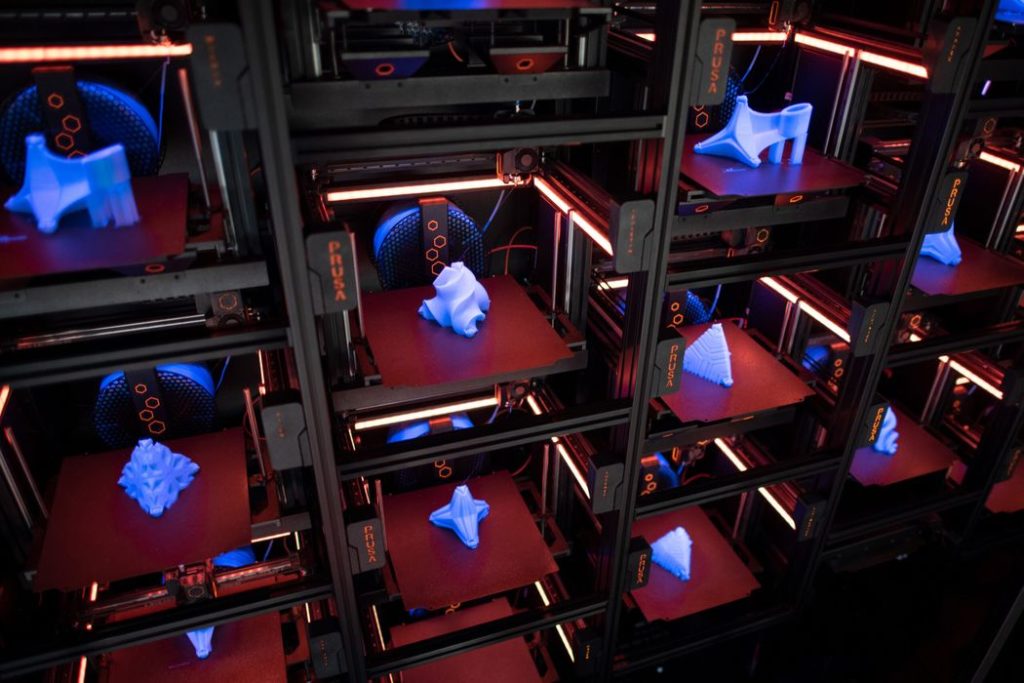

October: Prusa Research Takes Huge Step Into Manufacturing With The Automated Farm System

Prusa Research did make a very strategic move in October by announcing a factory array system that can be purchased for low volume manufacturing. This is not only an important product, but may also signal a shift in market focus for Prusa Research towards industry and farther away from their traditional desktop market.

November: Prusa Acquires Trilab and Moves Into Industrial 3D Printing

Another big Prusa Research story in November revealed the company’s purchase of Trilab, a Czech company that produces powerful delta-style 3D printers for professional and industrial use. This move complements the company’s factory announcement, and even more strongly suggests they are breaking into a new market.

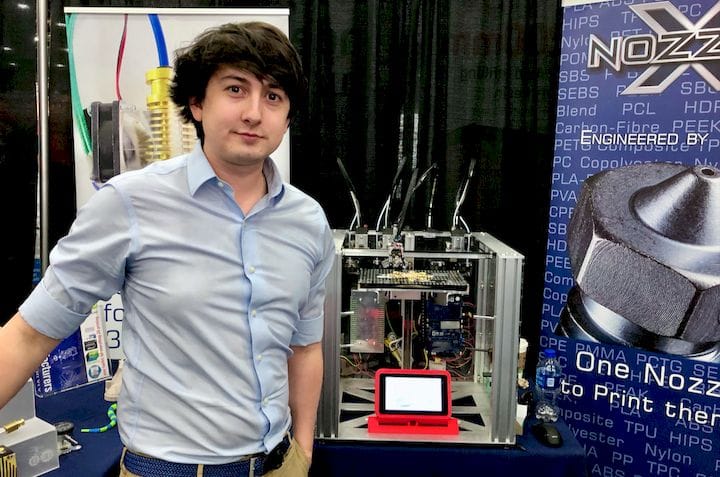

December: We All Lose Sanjay Mortimer

In December we unexpectedly lost Sanjay Mortimer, the founder of E3D-Online, producers of the industry standard V3 hot end, which revolutionized the industry. The company’s products have been behind many of the most successful 3D print ventures in recent years, and they were well-known for being the first to develop innovative components for 3D printers. Mortimer’s loss is a significant blow to E3D-Online and the rest of the industry, and it’s unclear how things will proceed from here.

Next Up: 2022.