Oqton announced it has raised a massive US$40M from investors.

The San Francisco / Belgium-based company was founded only in 2017, so it is in some respects still a startup. However, the US$40M investment is termed as a “Series A” investment. This type of investment is large and intended for recently established companies to aggressively grow their operations.

If you’re not yet familiar with Oqton, they are a bit challenging to describe. They don’t make 3D printers or materials, but instead provide an ingenious software infrastructure for additive manufacturing.

Essentially, they are trying to integrate multiple functions that are typically separate islands of activity in an additive operation. These include

- CAD — Computer Assisted Design

- PLM — Product Lifecycle Management

- CAM — Computer Aided Manufacturing

- IOT — Internet of Things

- MES — Manufacturing Execution System

- QMS — Quality Management System

While integrating these functions together is a notable achievement, Oqton does even more, as they apply AI techniques to the data flow to identify and apply optimizations and automations. For example, they say they can provide 100% automation to jewelry production, and save up to 30% by doing so.

This may sound quite fuzzy, but their system allows amazing things to be accomplished in short order by leveraging the AI-powered functions. For example, we previously reported on how they were able to very quickly design and build a universal quality control device for the factory floor.

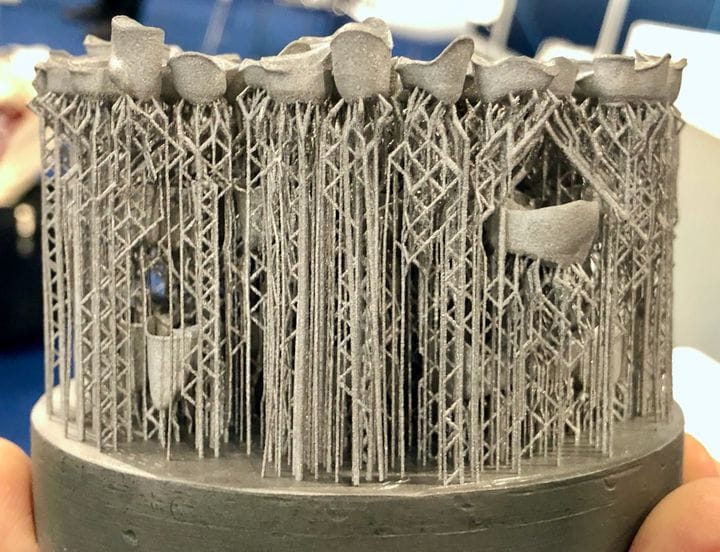

Another example we’ve seen is this incredible three-layer metal 3D print, where the support structures snake their way around each other to create extra prints within the same job to save time and materials.

This incredible functionality seems to have attracted investor attention, as the massive US$40M investment is larger than most investments in the space.

But what will Oqton do with this new cash? They explain:

“The financing will be used to further develop its platform, while expanding its commercial partnerships in multiple domains and verticals (Additive manufacturing, Robotic welding, CNC machining).”

Translation: more sales to get out the product they’ve already built, and secondly expand the product line by adding more manufacturing functions.

This makes a great deal of sense. If you think about what they’ve already done, you could say they vertically integrated the typical manufacturing sequence — but only for additive manufacturing. If they were able to do this for AM, then perhaps they can do something similar for those other types of manufacturing.

In fact, it may be easier to achieve as there are plenty of complexities in AM that don’t exist in other disciplines.

Another future possibility is cross-discipline integration, where a product might travel between these functions. For example, a metal part may be 3D printed, but then undergo CNC machining to finish its surface, and then be welded to other components.

The US$40M should be more than sufficient for Oqton to develop all this and likely much more. Today the company has partnerships with several established AM players, including EOS, Sisma, Trumpf, Prodways and Sandvik.

There will be more soon.

Via Oqton