3D print startup OPT landed a huge US$15M investment.

The company was founded only a couple of years ago by then-graduating MIT student Jifei Ou. You may have heard much about this relatively new company, but you certainly will in the future.

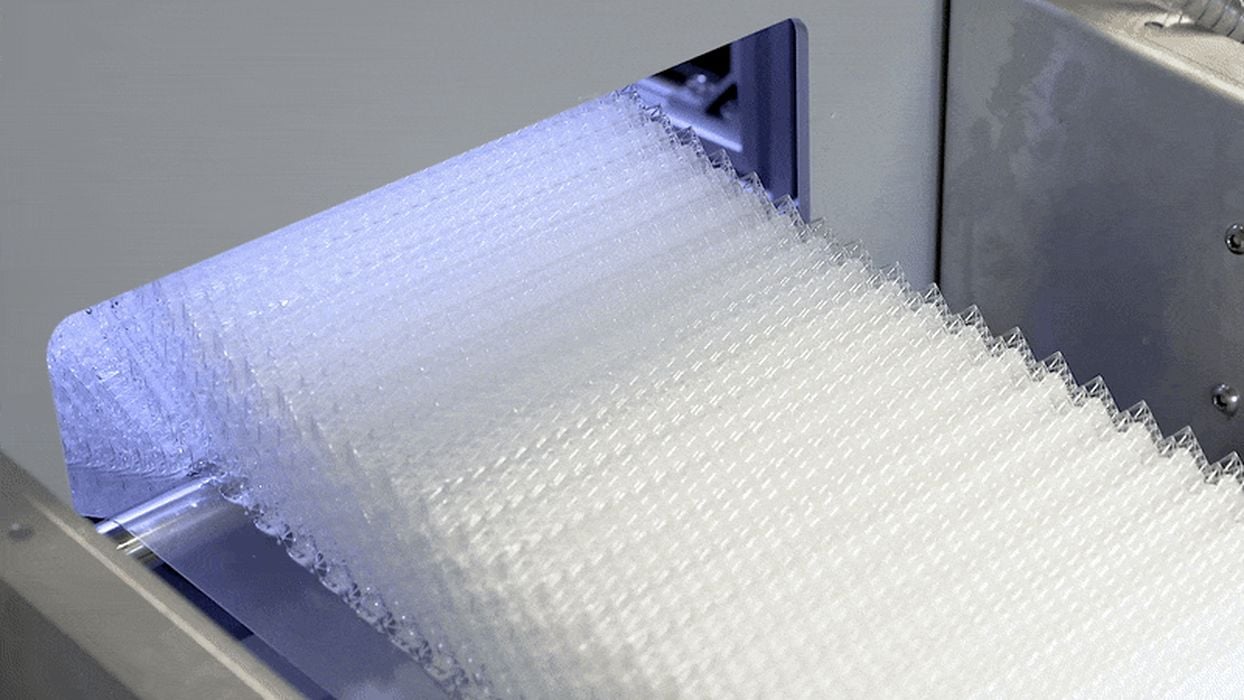

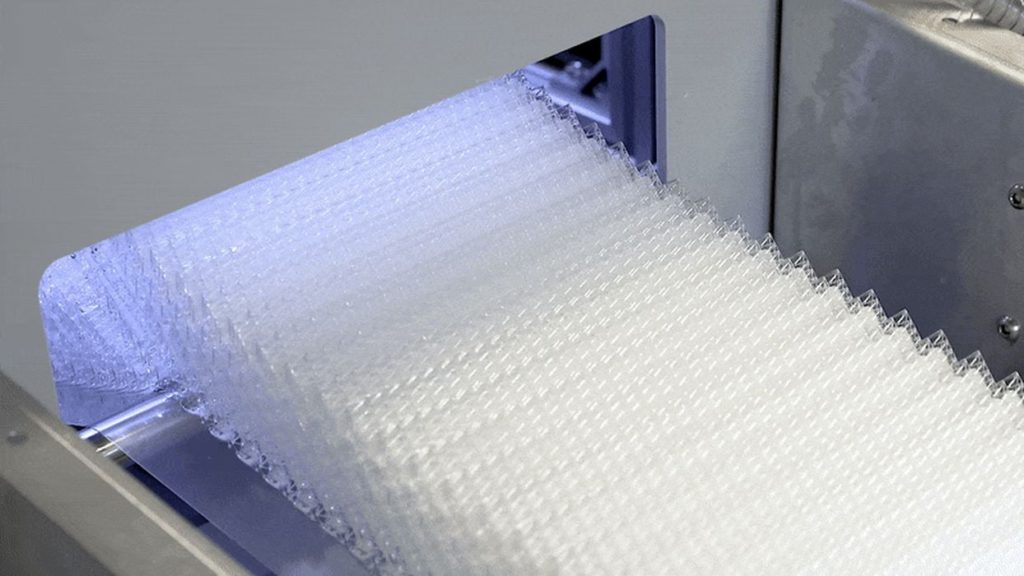

OPT Industries’ key technology is their RAMP 3D printer. It’s a resin-based system that does something no other resin 3D printer can do: print continuously. Don’t believe me? Watch this animation:

I’m still not exactly certain how this works, but somehow they have developed a method of rapidly curing photopolymer resin in a way that permits rapid creation of continuous objects as shown in the animation.

This process can potentially rapidly manufacture highly complex parts by leveraging the resolution of the resin printing process. In addition, OPT Industries specializes in metamaterials, the science of creating microstructures in a material that result in unusual macro-size properties. A simple example would be using a lattice to create a springy material, but OPT Industries’ science is way beyond that.

You can learn a bit more about OPT Industries in our previous interview with CEO Jifei Ou.

The news is that OPT Industries has received a massive injection of US$15M investment capital in a Series A round. “Series A” rounds are typically for companies that have proven a technology, but need cash to expand operations and grow. That seems to be where OPT Industries sits today.

Ou said:

“As an advanced manufacturing company, we see the value in building micro-scale technologies that solve macro-scale challenges. OPT works with customers to design and manufacture a novel range of metamaterials and products for the healthcare, automotive, cosmetics and consumer goods industries, and beyond. We will leverage the new financing to address the demand for InstaSwab™, fuel product development, scale operations and grow the team.”

Instaswab is OPT Industries’ current flagship product, a highly advanced test swab produced at scale on their RAMP system. They’ve attracted a number of clients due to the efficiency of the swab based on its use of metamaterials. OPT Industries said it is “20 times more effective” than typical swabs.

This demonstrates some of the potential of the RAMP system.

One aspect not mentioned in the company’s press release is their intentions with this new cash. Typically Series A rounds result in, for example, hiring a huge sales and marketing team to take the product to customers, or researching a new technology, or expanding a factory. What is OPT Industries going to do with this cash?

The answer might lie in their unusual business strategy. Most times a startup will invent a new type of 3D printer and the go about selling it to customers wishing to use it to make new kinds of products or make them more efficiently. That’s not at all what OPT Industries is doing.

Instead of focusing on manufacturers as clients, they instead are focusing on end-use products. OPT Industries becomes the manufacturer themselves. This allows them to avoid all the sales and marketing trouble of convincing stubborn manufacturers to change how they do their business, and enables them to refine the production process in house.

Because of this I suspect OPT Industries will do two things with the cash: expand their sales and marketing to find clients looking for unusual products to be manufactured, and secondly to expand their production capacity.

Apparently OPT Industries has already built out a huge 14000sf facility in Medford, MA for production, and I suspect they will need even more. Their success will be literally proportional to their manufacturing capacity; as their factories grow, so does their business.

Via OPT Industries