Charles R. Goulding and Preeti Sulibhavi look at recent usage of 3D printing in offshore oil rigs.

The demand for energy and the increase in oil prices has led to a global offshore drilling boom.

This was not the case in 2014 when oil prices began to crash, offshore drilling rigs were left stranded mid-construction in shipyards or sold for scrap. Large offshore drilling rig ships cost US$100,000 per day in 2016 when the industry reached its lowest point. Now, the industry is booming.

Companies such as Transocean Ltd and Noble Corp, which own and staff billion-dollar rigs such as the Titan are now able to charge oil companies US$400,000 each day for offshore drilling in the heightened search for petroleum.

Large drilling rigs are a combination of large ships and major drilling facilities. The 3D printing industry has made tremendous strides since the last low point in 2016. This includes advancements in both the shipbuilding and offshore drilling industries.

Recent Marine 3D Printing Developments

There are a myriad of recent marine 3D printing developments. Singapore is leading this maritime trend in the Asia-Pacific region. Due to the isolated location of offshore rigs and the limited ability to store spare parts, we believe that if each ship rig had a 3D printer on board it would benefit these companies in terms of time and cost.

Recent Oil and Gas 3D Printing Developments

Shell has been busy using 3D printing to create spare parts on demand and develop unique and customized equipment. Shell has found that they are able to rapidly prototype engineering designs and develop an internal ability to apply 3D printing to the energy industry. Shell has successfully installed the first 3D printed leak repair clamp in service. Clamps, also known as mechanical leak repair enclosures, are engineered solutions that are used to encapsulate and restore the integrity of operating pipelines against pipeline defects or wall thinning arising through erosion and corrosion mechanisms. This is a big move for a big oil company.

Likewise, in 2022, Chevron, utilized Lincoln Electric metal 3D printing technology to produce replacement parts during a supply chain crisis for the company. Chevron benefited from Lincoln Electric’s wire-based metal 3D printers to print critical replacement parts that met both production and quality standards. This was both a time and cost-effective strategy.

In the marine and offshore industry, organizations must develop innovative and sustainable concepts, and deliver cost-effective and budget-friendly solutions, all while complying with stringent safety and environmental regulations. 3D printing provides manufacturers with prototyping, advanced tooling, and production applications. 3D printing solutions are often the difference between turning down potential business and cost-effectively delivering and serving a niche need.

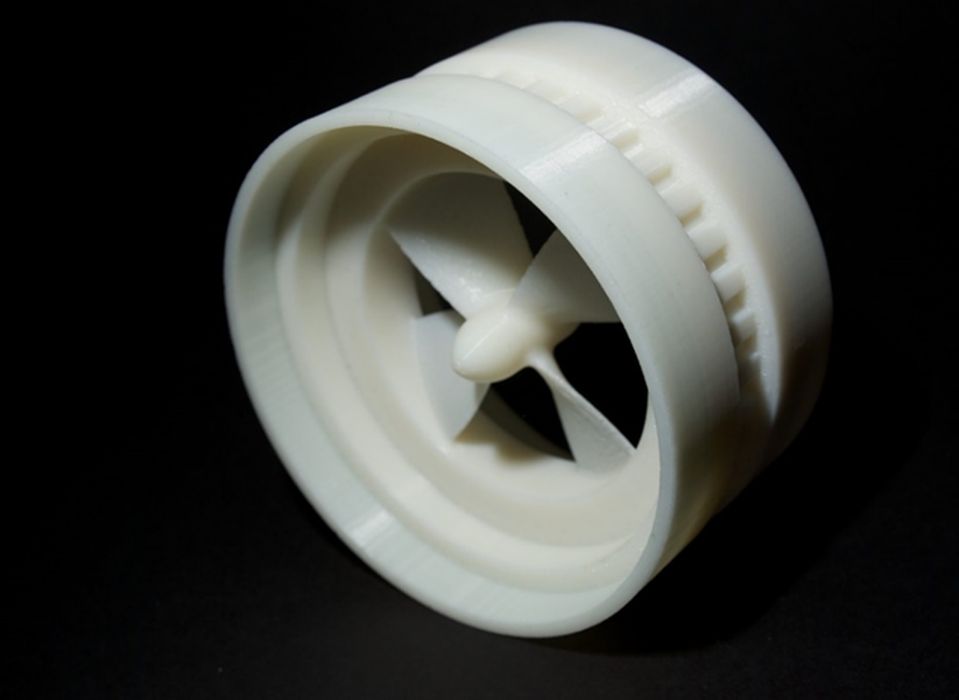

We have also covered the boat, shipbuilding and marine industries in some depth on Fabbaloo. There are notable applications of 3D printing in these industries, whether it is for propellers or various replacement parts 3D printing is helping achieve high-quality results.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The oil and gas industry has increasingly been integrating 3D printing into its processes. With the uptick in demand for offshore drilling due to the increased demand for energy, this is the opportune time for the industry to tap into 3D printing.