Have a clog in your FFF 3D printer? The NoClogger might be just what you need.

Clogs are a frequent issue in desktop Fused Filament Fabrication (FFF) 3D printers, and they come in various forms. One of the most common is when filament gets stuck in a way that prevents it from flowing due to temperature. The NoClogger, a new screwdriver-style tool, might be the solution you need for these stubborn clogs.

Traditional Clog-Clearing Methods

Typically, clogs are addressed by “persuading” the hot end to behave, often using an “acupuncture-like” needle applied from the bottom of the nozzle. Sometimes these needles are included with the 3D printer, and sometimes they’re not. They work occasionally, but not always.

An alternative clog-clearing approach is the “cold pull” method. This process involves heating a filament in the hot end and allowing it to cool. As the filament reaches sufficient solidity, it is quickly pulled out manually, grabbing any loose bits causing flow issues. However, this method is time-consuming due to warm-up and cool-down delays.

How the NoClogger Works

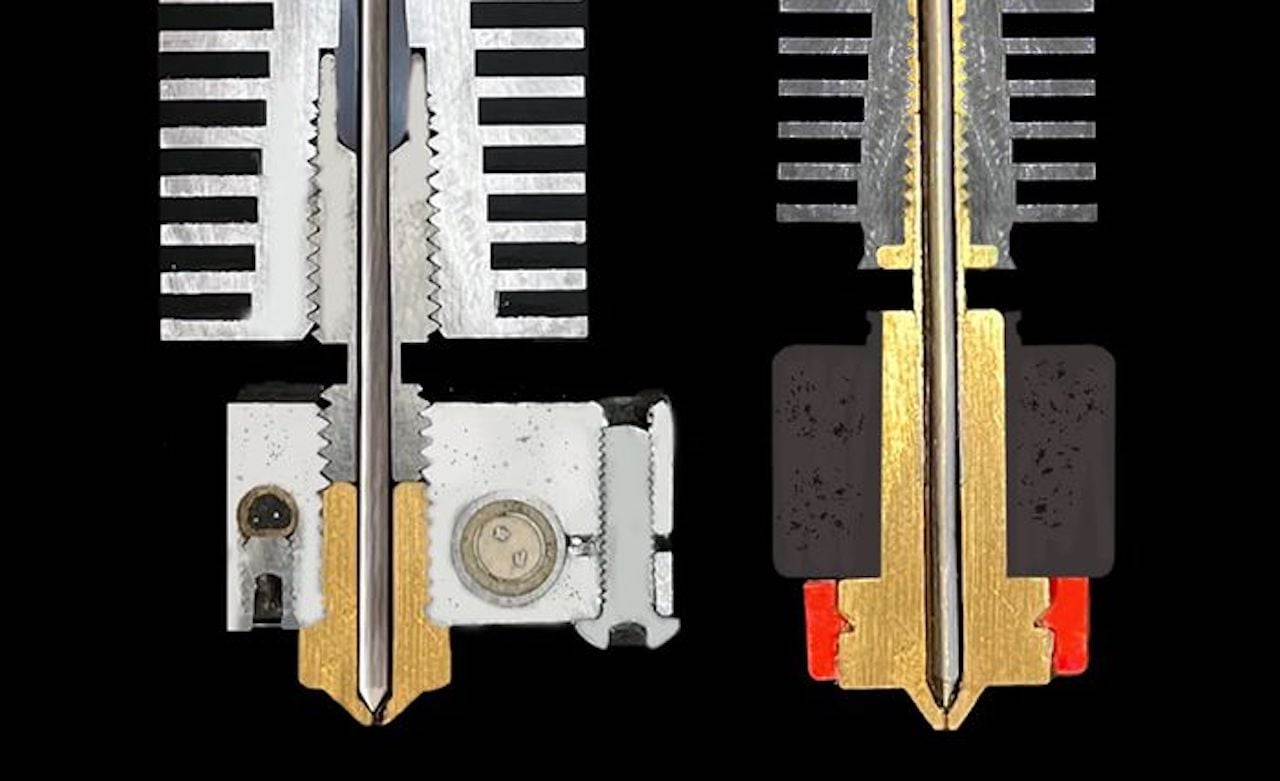

The NoClogger is a specially designed tool that tackles some of these challenges. It is inserted into the hot end from the top instead of the bottom. Its end shape closely matches the heating chamber’s shape deep within the hot end, allowing it to push anything inside the hot end out through the nozzle using pure force.

To use the NoClogger, heat up the nozzle without a filament inserted (but with a clog). Once at temperature, insert the NoClogger down the filament path. You may need to “open” the extruder gear for this to happen, but that’s easy to do. This tool can easily clear most jams and is simple to use, as demonstrated in this video:

Compatibility and Versatility

The NoClogger works with both direct and Bowden-style extruders and is available in versions for 1.75mm or 2.85mm setups. Its extra-long design means it can be used with almost any hot end and can even clear out bits from Bowden tubes.

However, the NoClogger may not fix all types of clogs. For instance, when using wood or composite filaments with fibrous matter mixed with the polymer, larger fibers can occasionally cause clogs. While the NoClogger might be able to push these fibers through the nozzle with enough force, there’s also a chance they may get tamped down at the bottom of the hot end, requiring a return to the cold pull method.

A Worthwhile Investment

If you operate FFF 3D printers, the NoClogger is a tool you should consider, retailing at approximately US$20 each. It’s a worthy investment for hassle-free 3D printing.

Via NoClogger