Volumetric 3D printing is the future, but it’s had a significant limitation: it must use transparent resin. Until now.

Volumetric 3D printing is utterly different from today’s common 3D printing processes such as FFF, SLA, SLS and others. It uses a rotating vat of resin, which is continuously illuminated with a series of “X-ray” images of the intended object. As time passes regions within the vat eventually accumulate sufficient energy to trigger polymerization. “Time” in this case means only minutes or even seconds to complete an entire 3D print job.

While the speed factor of volumetric 3D printing is obviously attractive, there has been a significant problem: in order for the light energy to travel all the way through the resin vat to reach the intended locations in 3D space, the resin must be basically transparent, at least to the wavelengths used for polymerization.

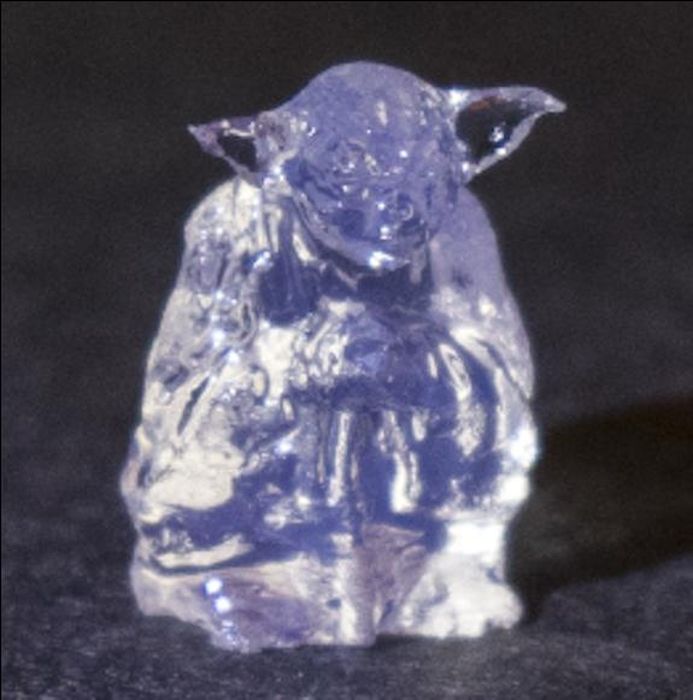

That’s why all volumetric demonstrations seen up to now involve vats of clear resin. Opaque resins would scatter the light beams as they traverse the vat, leading to corrupted prints and poor quality objects.

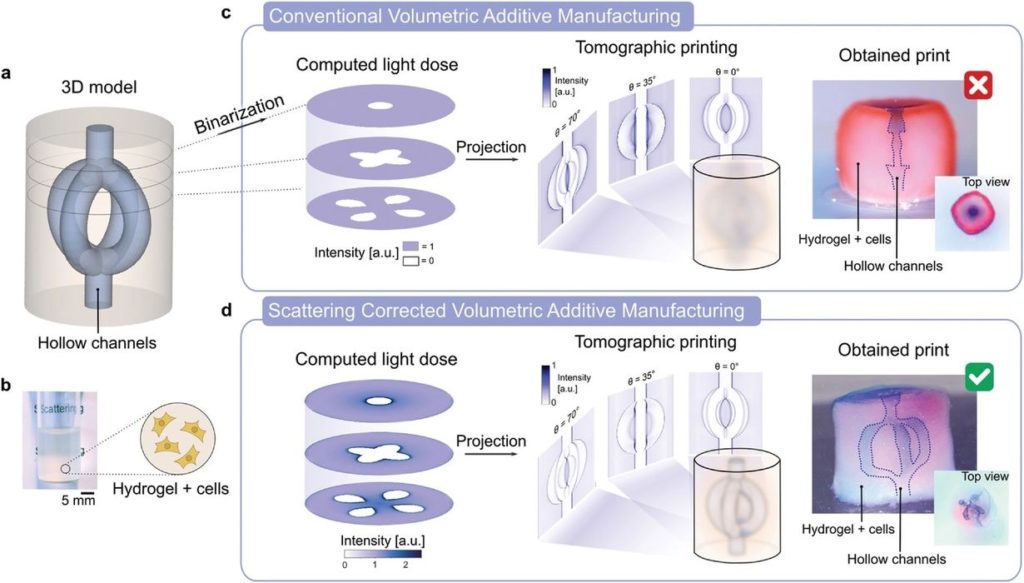

New research at EFPL in Switzerland seems to have found a way around this effect, at least for partially opaque resins. Their strategy is to account for the scattering when developing the projection patterns: the deeper into the vat, the more scattered the light will become. They explain:

“Herein, a method that takes into account light scattering in the resin prior to computing projection patterns is proposed. Using a tomographic volumetric printer, it is experimentally demonstrated that implementation of this correction is critical when printing objects whose size exceeds the scattering mean free path.”

How is this achieved? Apparently they used a pilot beam to observe the scattering for the basis of the adjustments. EFPL explains:

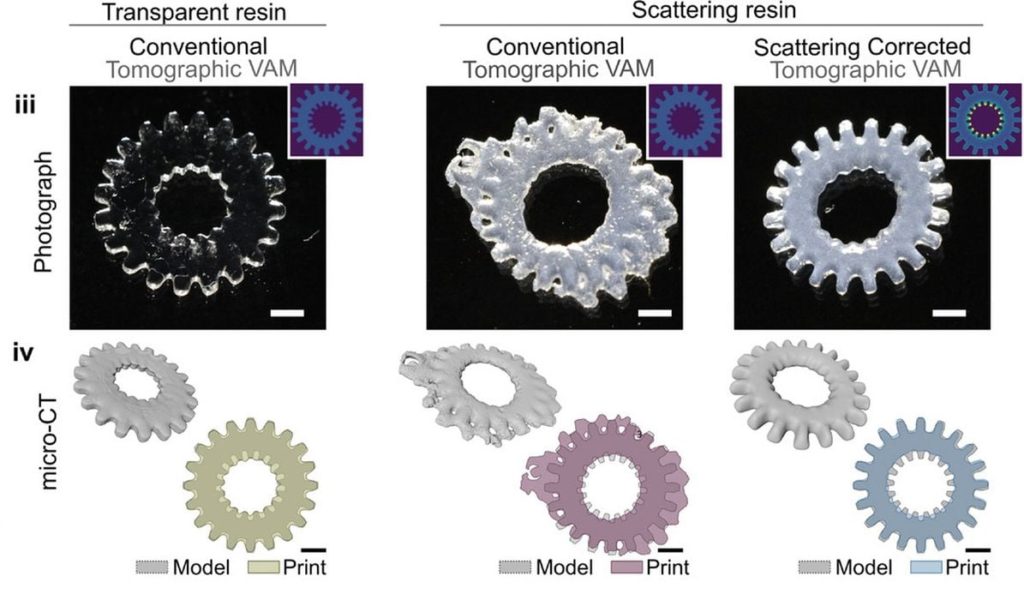

“The solution that the engineers found was actually quite simple. First, they used a video camera to observe the light’s trajectory through the resin and then designed computer calculations to compensate the light-ray distortion. They programmed their printer to run these calculations and correct the light rays as the printer operates. This made sure that the amount of energy needed to solidify the resin would be reached at the desired spots. By adjusting the computer calculations, the engineers were able to print objects in opaque resin with almost the same precision as for transparent resin – an important breakthrough.”

The objects printed are not fully opaque; if they were then no light propagation would occur and volumetric printing would not work at all. However, the ability to use slightly opaque resins is quite important.

This is because in 3D printing resins are often mixed with additives to gain new engineering properties, such as thermal resistance, coloration, flexibility, etc. These additives are typically not transparent, and so if added to a clear resin they would make it slightly opaque.

In other words, this development opens up the possibility of using a much wider range of practical resins for volumetric 3D printing.