Humabiologics’ human-derived bioinks are now available for use on Allegro 3D bioprinters.

When scientists and clinicians study disease, they rely on the traditional progression of bench experiments to animal models. Since this is a time-consuming process with high failure rates, researchers need alternatives that can replicate the complexity of the human body in an inexpensive and accessible manner.

The emerging field of experimental organoids—layers of tissue and vasculature that resemble an “organ in a dish”—has helped to bridge the gap between bench work, animal models, and clinical trials. However, these three-dimensional, multicellular constructs require sequential stem cell development and careful maintenance.

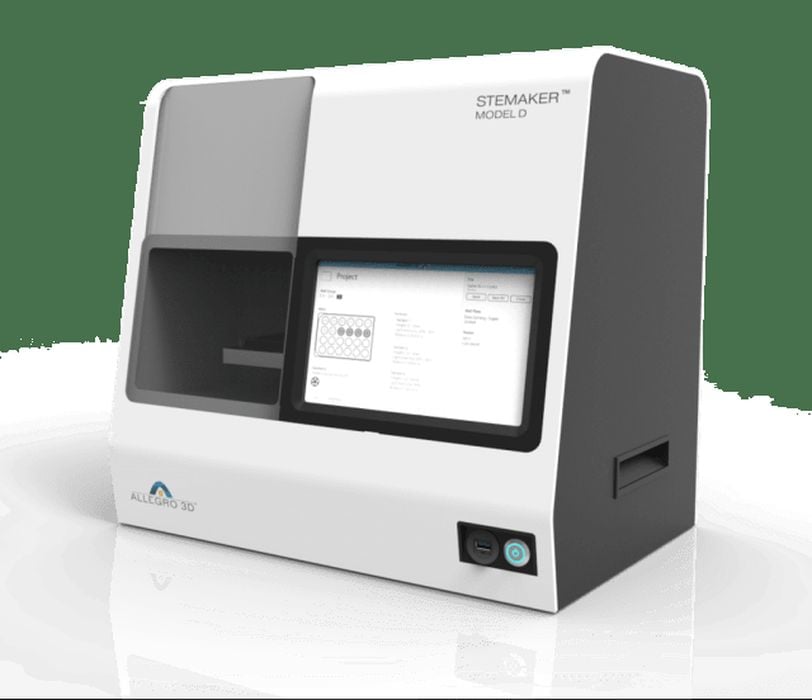

The use of bioprinters is gaining popularity across diverse fields of research and medicine as an inexpensive and effective alternative to traditional animal models. To accelerate the development of 3D tissue models, Humabiologics, a leading company in human-derived bioinks, recently partnered with Allegro 3D to advance bioprinters and help researchers and clinicians develop better tools for studying disease.

Animal Models Are Limited and Expensive

For decades, scientists have warned of the limitations of animal models as an approximation for human health and disease. Researchers have determined that results of drug trials and disease experiments are often dependent on the specific type of animal model used, identifying artifacts in data collection depending on the species and living conditions of animal subjects. For example, the microbiota—the community of microbes living inside an organism—affects the biology of mouse models of colorectal cancer. For years, this complicated our understanding of how the disease develops and prevented identification of novel chemotherapeutic agents.

Scientists cannot advance early-stage, experimental therapeutics directly to clinical trials, and it is often difficult or unethical to study the origins and development of disease in humans. To improve medical research, scientists need reliable, inexpensive models of human tissues that can be used in the lab to study how disease emerges and discover new ways to treat illness.

One elegant solution to this problem is using human-derived cell lines, stem cells, and other patient samples. Although many labs use these cell lines in the early stages of experimentation, they are also limited when it comes to accurately reflecting the 3D architecture and complexity of human tissues. With the widespread adoption of 3D printing, scientists realize the potential of using 3D printed tissues as an excellent approximation of human complexity within a laboratory environment.

What Is 3D Bioprinting?

Over the past several years, the United States Food and Drug Administration (FDA) approved multiple 3D printers for use in clinical settings, including for orthopedic and restorative devices. Most of the current applications of 3D printing in healthcare and biological sciences involve non-living constructs used for protheses, training, or custom equipment. But the potential of 3D printing goes well beyond synthetic, non-living prospects. The emerging field of 3D printed biological samples stands to revolutionize medicine and basic biology research.

3D bioprinting involves the same principles as 3D printing but relies on “bioinks” composed of living cells or active biomolecules. The layer-by-layer printing process allows bioprinters to deposit these bioinks to create 3D structures, including human-derived tissues.

There are three main types of bioprinting: extrusion, inkjet, and laser-assisted. Extrusion bioprinting uses a pressure-based system to create continuous filaments deposited on a substrate such as a gel matrix or culture plate. As the name implies, inkjet bioprinting uses the same process as inkjet printers you might find in your home or office. These bioprinters will deposit a small amount of bioink onto a hydrogel surface without direct contact. Finally, laser-assisted bioprinting uses the energy generated by a laser to deposit biomaterials onto the substrate of interest.

Read more at ENGINEERING.com