Researchers have created a unique nanoprinting process that can produce extremely small objects in a wide variety of materials.

The Australian and American researchers wanted to develop a different approach for nanoprinting, the process for 3D printing very small objects in the nanometer range. Currently this field is dominated by the two photon process, where small vats are targeted by extremely precise lasers. While this has been a very successful process, it has some limitations on the material types possible because the resin must include photoinitiators.

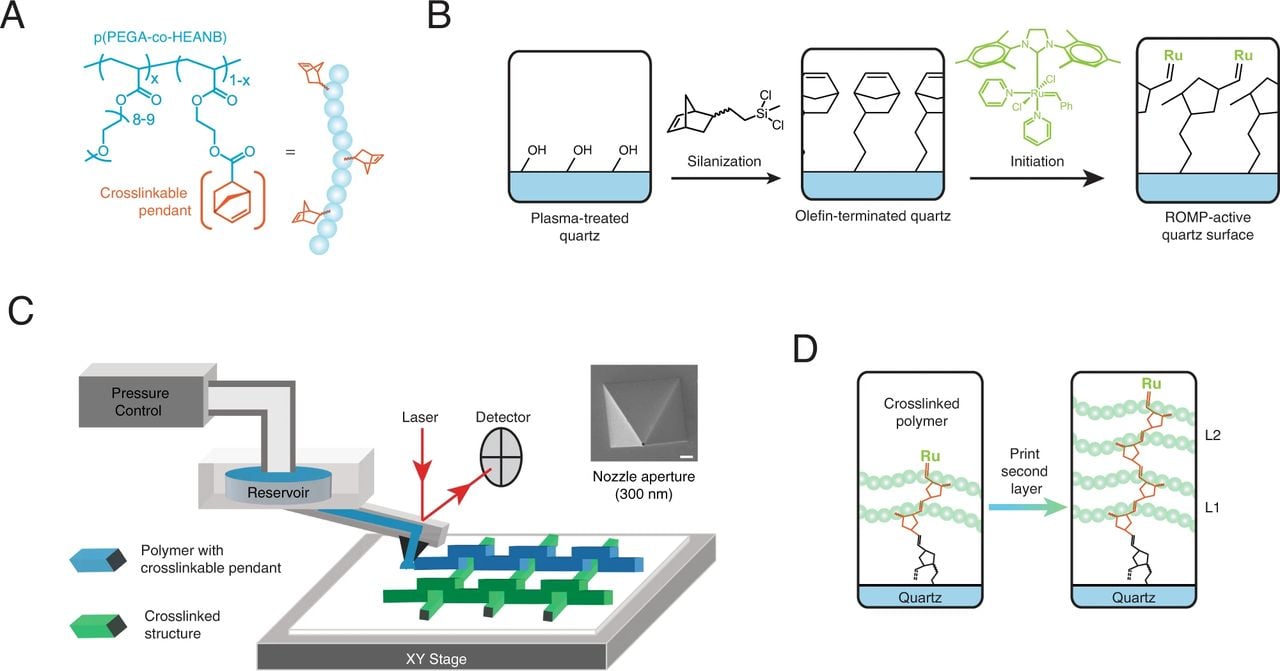

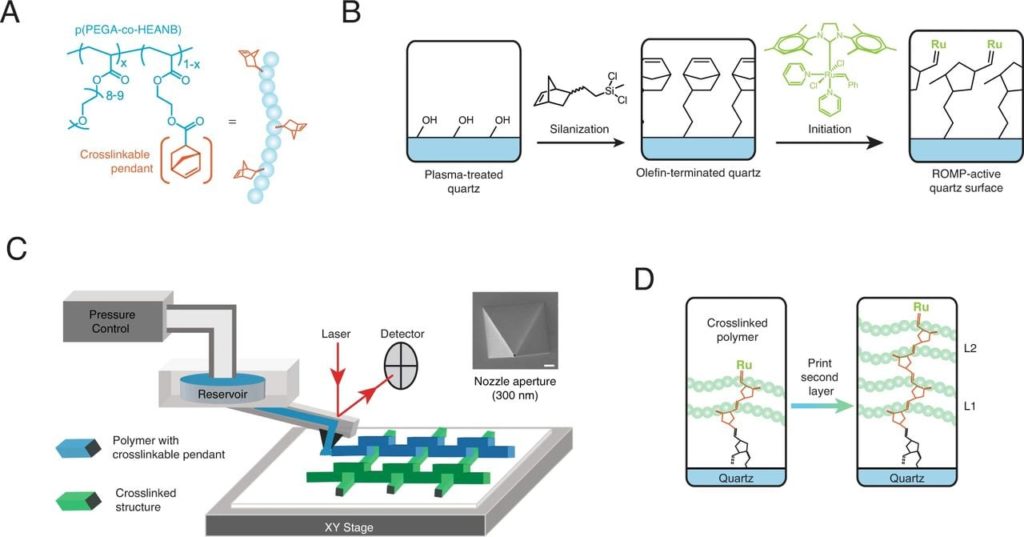

The new process is quite different, and the researchers have termed it “spatially controlled assembly and polymerization”.

The key component of the new system is a microfluidic-coupled atomic force microscope, which delivers the specialized cross linked polymer to a catalyzed surface. It seems that contact with the surface initiates polymerization automatically, which occurs very rapidly.

The researchers were able to use this approach to 3D print extrusion lines as thin as 450nm across (0.00045mm) and on the z-axis as thin as an invisible 2nm (0.000002mm)!

The surface used was quartz, heated by plasma. Evidently this combination is what causes the polymerization to occur.

The researchers were able to control the width and height of the extrusion by playing with the pressure exerted by the atomic force microscope. They explain:

“We also investigated the activity of the catalyst by depositing lines with an increasing number of passes, and then rinsing the surface to reveal stable polymer. When printing with the 300 nm aperture tip at 10 µm/sec and 1000 mbar of reservoir pressure, an increase in line-height was observed up to 30 depositions. Beyond this, the line height did not decrease. This corresponded with a line-height of 200 nm and indicates the burying of catalyst within the printed structure so that it can no longer crosslink further depositions without additional reinitiations.”

They say that this new process is actually somewhat slower to print than the two photon approach, but provides more material breadth. They explain:

“Our approach, although slower in terms of printing speed, enables broader applications as we could print various materials without being restricted to using materials that contain photosensitive or photoactive molecules. Thus, this methodology could save time overall, as it reduces the time required to synthesize molecules containing photoactive functional groups, and in the preparation of photolithography such as formulating the crosslinking mixture and solubilizing photoinitiator, or pre-baking a photoresist layer.”

The new process is also potentially able to deposit different materials on each layer, whereas two photon approaches must use only a single material for the entire print.

As of this writing, this science has not been commercialized. However, it does sound quite promising and I have little doubt that some parties will attempt to develop it further to the point where it could become a product.

However, the nature of the process seems quite different and more challenging to implement than other processes. When I see words like “quartz”, “plasma”, “atomic force microscope”, it’s going to be expensive.

Via Nature