MIT researchers have 3D printed a key component of mass spectrometers that could result in significant change.

Mass spectrometers are a specialized sensor that can identify the elements within a given physical sample. They work by ionizing the input material and then accelerating it with an electric field. The particles deflect in different directions during this process, which allows the identification of specific elements.

In other words, a mass spectrometer can tell you what an object is made from. They are used in many areas of science and exploration.

However, there’s a problem. Mass spectrometers are quite expensive, sometimes costing six figures or more. This has greatly limited their use to only applications where significant value is obtained.

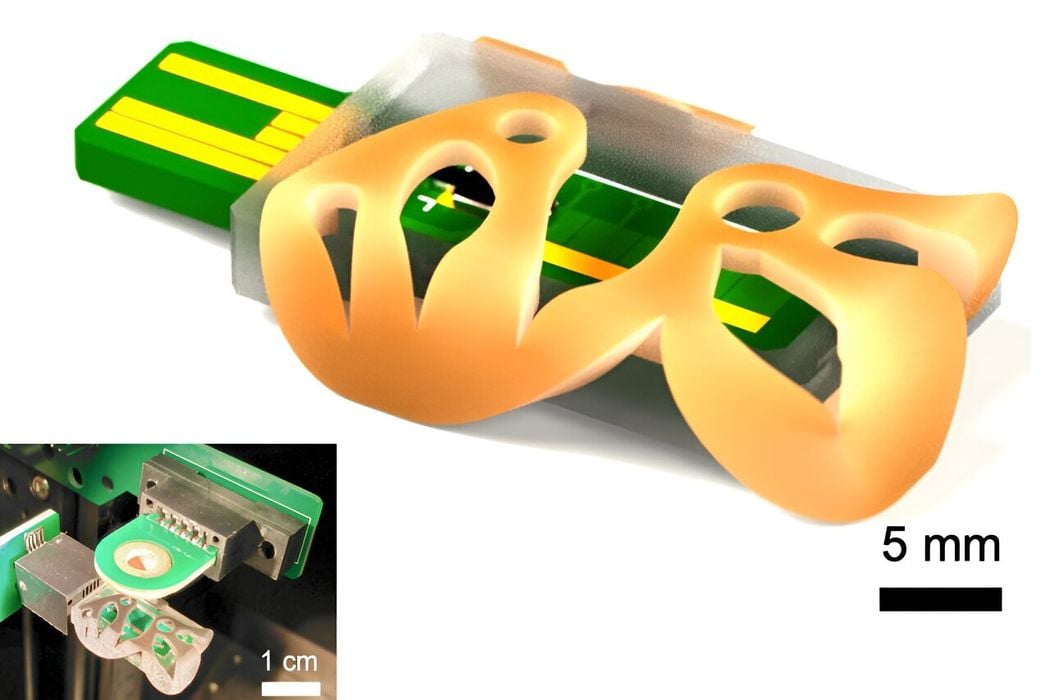

That could change with a new process developed by MIT researchers. They were able to 3D print an “electrospray source” for a mass spectrometer that is able to perform the ionization part of the process.

Even better, their 3D printed source was found to have improved performance over conventionally made components. For example, the 3D printed version achieved 116% improved signal to noise ratios, and 24% higher bias voltages.

The researchers explain:

”To the best of our knowledge, the surface-mounted emitters reported in this study are the first to be compatible with automated electronics assembly, eliminating issues associated with fragile capillaries or inefficiencies from alternatives, such as paper spray. The emitters are bulk fabricated in arrays via 3D printing, facilitating batch processing and scaling. High-resolution 3D-printing is ordinarily expensive for single-use parts but could enable substantial benefits at scale due to the compact size of the surface-mounted emitters.”

This suggests that the cost of this component could be lowered in future mass spectrometer designs if this process is used. That could lead to increased use of mass spectrometers and entirely new applications.