Several new AM materials were announced in the past couple of weeks.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

Stratasys To Increase Materials Selection

Stratasys hinted at forthcoming announcements regarding increased materials selections for their burgeoning 3D printer portfolio, which now includes stereolithography, SAF, FDM, P3, and PolyJet processes. They’ve been working with chemical players Arkema/Kimya, Victrex plc, and Covestro to develop these upcoming materials.

Stratasys President EMEA Andy Langfeld said:

“Over the last two and half years, our focus has expanded from building up our hardware portfolio to working with key industry partners to develop a wide-range of use-case-specific solutions. These complete solutions encompass hardware, software, materials and services that create new business opportunities for our customers. We continue to accelerate cutting-edge developments in additive manufacturing and advance our strategy of providing the best and most complete polymer 3D printing portfolio in the industry.”

Carbon’s Bioabsorbable Elastomer

Carbon announced their new “biosorbable” elastomer has been proven to be biocompatible “in vivo”, meaning “performed or taking place in a living organism.” They explain:

“Carbon’s developmental bioabsorbable elastomer offers impressive mechanical performance, biocompatibility, and tunability. This includes an absorption rate that can be tuned to suit a variety of potential applications, making it versatile for a broad array of medical uses. Additionally, current in vivo studies have demonstrated the required tissue tolerance and desirable healing responses for an implantable device through 26 weeks.”

The implication here is that using this material it would be possible to 3D print custom soft implants for patients. Carbon suggests applications including: soft tissue repair, wound dressings, nerve conduits, space fillers, and temporary mechanical supports.

These are very likely entirely new applications for 3D printing that would not otherwise be possible without this type of material.

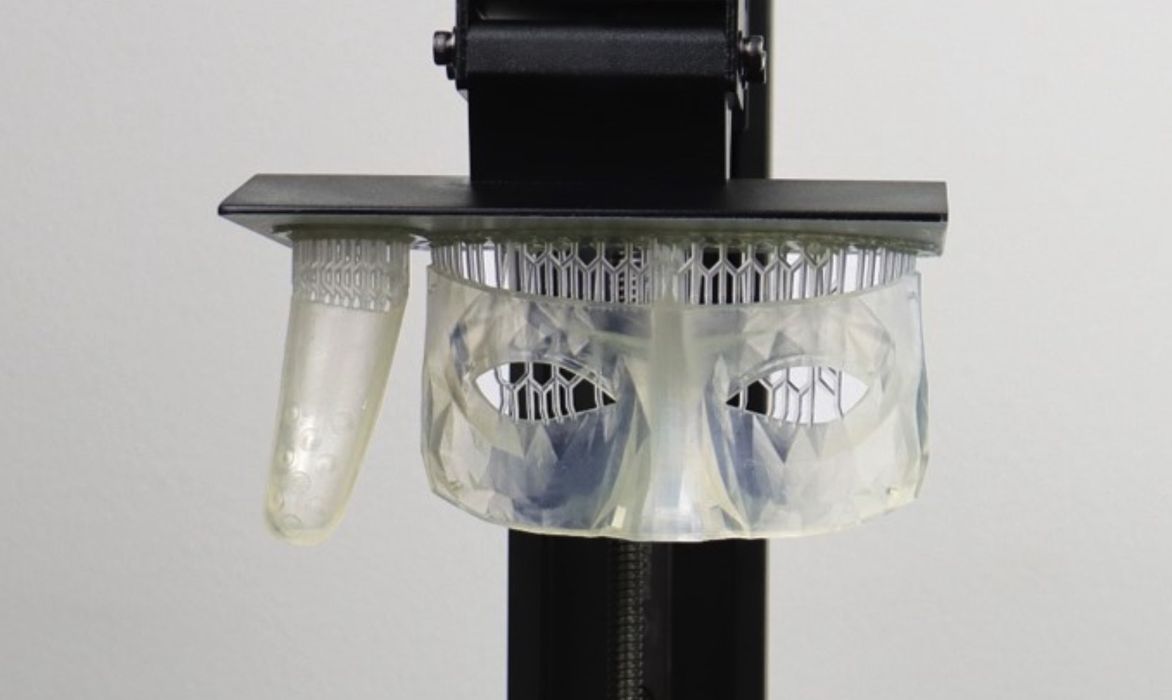

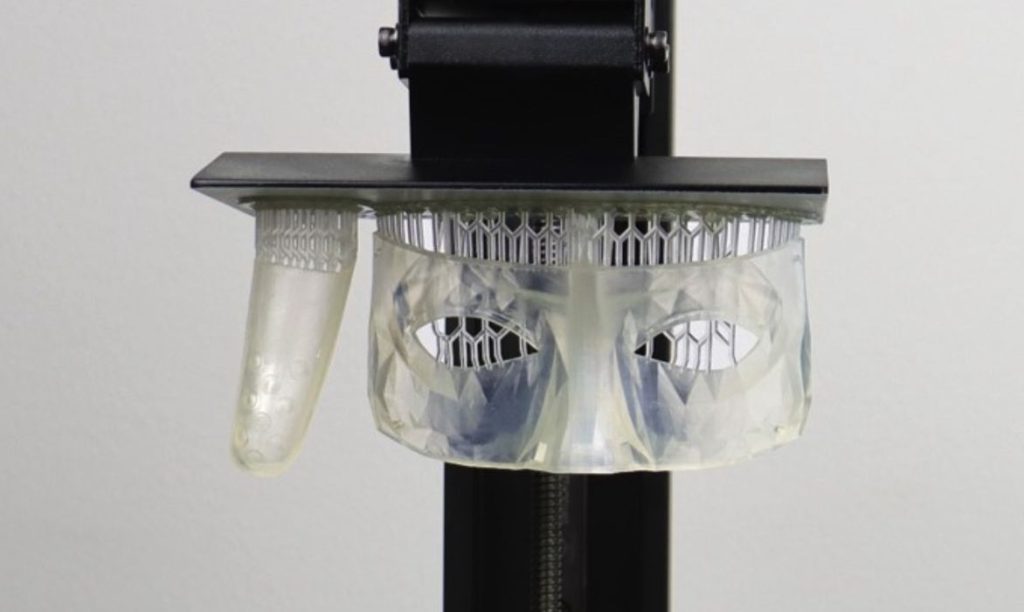

Liqcreate Releases Silicone-like Resin

Liqcreate released “Elastomer-X”, a new resin that is compatible with almost all desktop resin 3D printers (385-420nm). The unique feature of Elastomer-X is that the parts produced are extremely soft, having a shore value of only 43!

Liqcreate explains:

“Liqcreate Elastomer-X is a clear photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material are exceptionally soft with a Shore A of 43 and feature great flexibility. The product can be used as received, or colored with almost any commercial available 3D-resin colorant. Liqcreate Elastomer-X can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Its properties simulate soft TPU and silicone which makes it perfect for the production digital lattice foams, soft end of arm tooling (EOAT) for robots, grommets, bellows and elastic industrial parts.”

This is quite a significant announcement, as this could reduce the need for purchasing dedicated silicone 3D printers, which are rare and more expensive than standard desktop MSLA devices.

Cubicure and UpNano Develop Heat-Resistant 2PP Resin

Cubicure teamed up with UpNano to develop a new type of resin specifically for 2PP (two-photon) nanoprinting. The new material, “UpThermo”, is able to withstand higher temperatures after printing, said to be up to 300C.

Evidently the use of 2PP nanoprinting technology has been limited in industry because of the poor thermal resistance of prior materials. In particular, the electrical industry often requires components to be able to withstand higher temperatures for safety reasons, and the new UpThermo resin should be able to meet that demand.