Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

Stratays Announces 16 New Materials

Stratasys announced a spread of no less than 16 new 3D print materials for their ever-growing spectrum of 3D printing processes. An arrangement with Covestro, Kimya/Arkema and Victrex will enable the use of PEKK-SC, LMPAEK, PA6/66 GF20 FR, PC FR and HIPS for use in their FDM systems.

For Stratasys’ Origin One system, they have added eight materials from a list of providers to their open materials program. These include casting resins, ceramics, ESD, elastic and other advanced functions.

Finally, they’ve added PP to their H350 system, which should be of great interest to manufacturers using the system.

Zimple’s Zilament

Zimple has developed a new PETG material:

“For our very first 3D printing material, we wanted the best for outdoor use and for the environment, so we developed the Zilament : a recycled PETG loaded with organic compounds, and, made in France from European materials!”

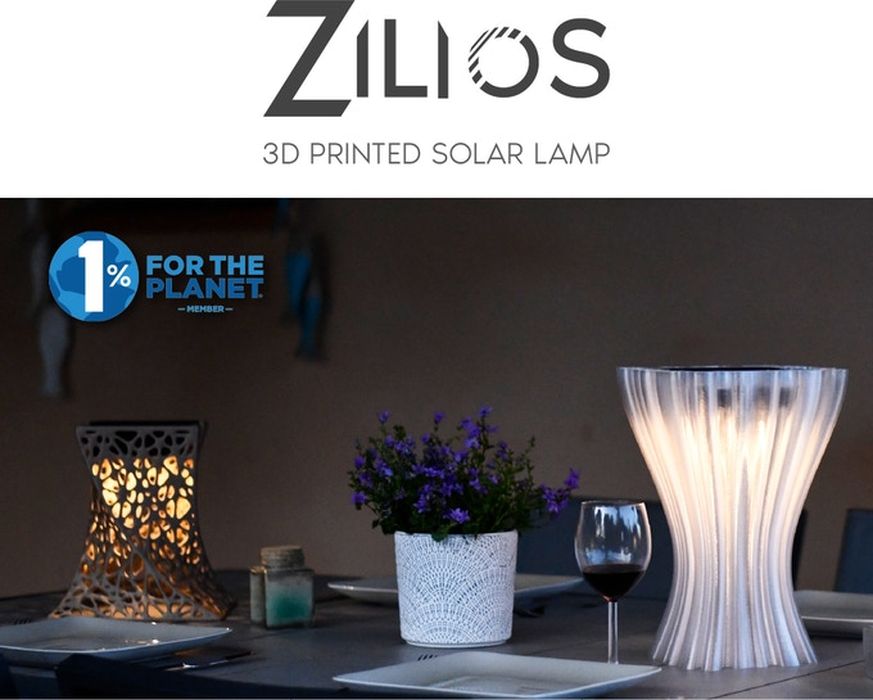

The material does not yet appear for sale, but is being used in some of their products, most notably on their latest Kickstarter project involving 3D printed outdoor solar lamps.

New Formlabs Resins

Formlabs announced two new engineering resins, PU Rigid 650 and PU Rigid 1000. These are both polyurethane materials that provide unusual properties. Formlabs explains:

“Both materials enable users to break free of the limitations of traditional polyurethane manufacturing with newfound design freedom, reduced production costs, and increased workflow efficiencies. PU Rigid 650 Resin can be used to produce impact resistant and pliable parts that can maintain dimensional accuracy under load, while PU Rigid 1000 Resin can be used to produce semi-stiff, sturdy and unyielding parts that repeatedly endure high stress environments.”

BCN3D Partners with Henkel on Viscous Resins

BNC3D is linking up with chemical giant Henkel to produce new materials for the company’s new 3D printing process, VLM (Viscous Lithography Manufacturing). The companies are not yet telling exactly what they are working on, but BCN3D said:

“The materials currently under development by Henkel and BCN3D cannot yet be fully disclosed; however, one of the primary areas of research is in elastomeric applications – one that is indubitably beneficial from high-viscosity resins. These materials can include a high fraction of oligomers to obtain a loosely crosslinked polymer network: a structure that can flexibly withstand mechanical stresses, act like industrial-grade molded elastomers, and provide improved mechanical properties.”