Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

Roboze Helios PEEK 2005

Roboze introduced Helios PEEK 2005, a new high temperature filament for their equipment, to be available this month.

Helios is a very interesting material, as it is a composite of PEEK and ceramic filler. The ceramic material makes the resulting parts stronger at higher temperatures. Roboze said parts made with Helios PEEK 2005 are able to provide significant thermal insulation even at a scorching 170C. This material should be of great interest to anyone making parts exposed to high temperatures.

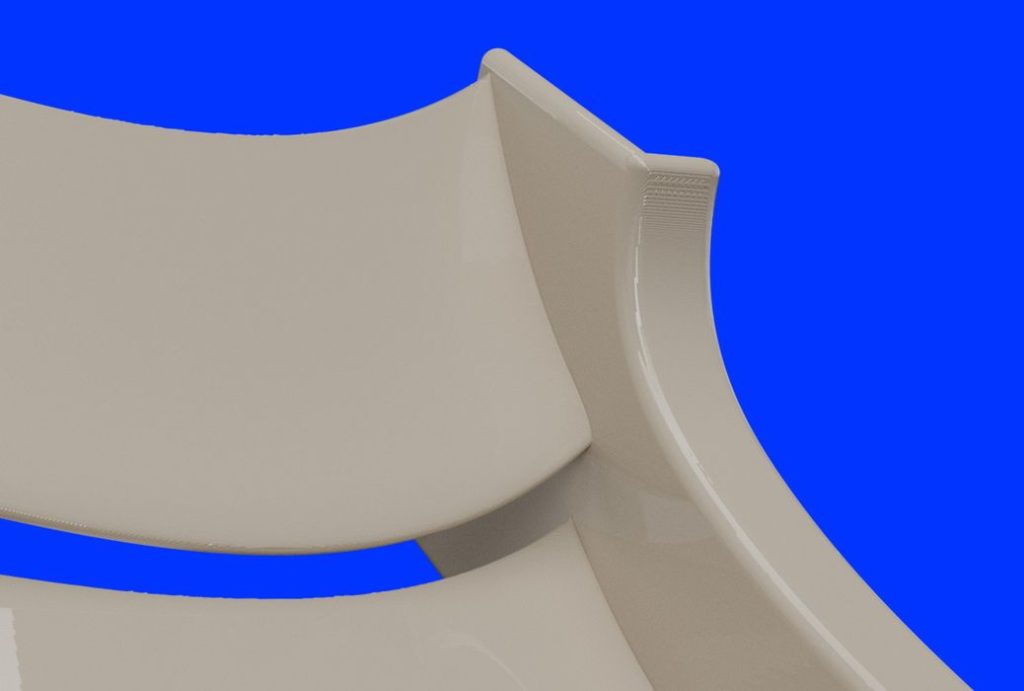

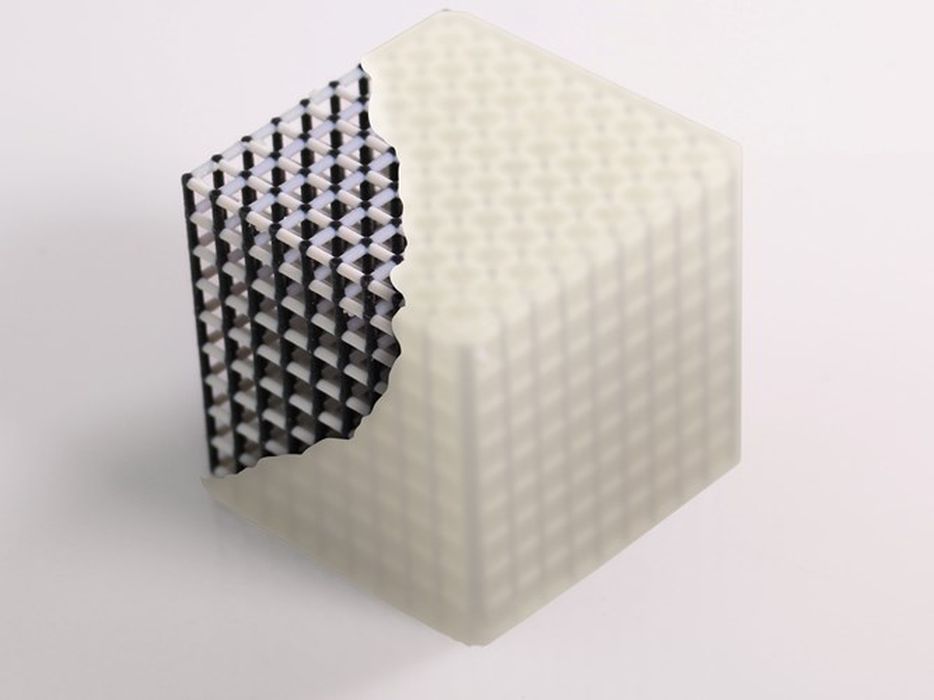

Roboze also made a point of explaining that the ceramic filler is made from particles much smaller than are found with typical fiber composites. This means that parts can be printed with thinner walls and finer details can be achieved, as you can see in the image above.

Formlabs Glass Filled Nylon 12

Formlabs announced a new strong material for their SLS Fuse 1 system. It’s a PA12 material that is mixed with a proportion of tiny glass fibers. This additive makes the corresponding printed parts much stronger than with just PA12. It also provides a bit more thermal resistance. It’s likely Fuse 1 operators will use the new GF material for parts requiring additional stiffness.

The new Nylon 12 GF Powder is available in black color, which makes it easier for the Fuse 1’s laser to sinter it: more light energy is absorbed. On the other hand, the black color prevents color dyeing the parts during post processing.

This is the first composite material offered by Formlabs on the Fuse 1, as the two previous materials, PA11 and PA12, were “straight” polymers only. Could we see a carbon fiber resin coming up in the near future?

Stratasys’ Water Soluble WSS150 Material

Stratasys announced WSS150, a new water soluble material intended for support structures. WSS150 is a resin to be used with the company’s PolyJet technology.

PolyJet prints require a considerable amount of support material because overhangs of any degree must be supported: the resin is deposited as a liquid, and it must have a surface to land on. Previous support material worked very effectively, but required water with additives to dissolve the structures.

The new WSS150 material is entirely soluble in plain water, meaning there are no additives required, nor concerns about waste water disposal. Stratasys said the material allows support removal with effort in water, or even in common dishwashers. This should greatly simplify post-processing of PolyJet prints on the J35 Pro and J55 Prime devices that currently permit the use of WSS150.

Evonik’s Osteoconductive VESTAKEEP Fusion PEEK

Evonik announced a new PEEK filament that is targeted for 3D bio prints in the healthcare sector. The new material is VESTAKEEP iC4800 3DF, which is osteoconductive.

“Osteoconductivity” is the property of a material to enable bone-making cells to occupy and gradually replace a scaffold structure. With the new VESTAKEEP material it would be possible to 3D print bone scaffold implants that could allow new bone to grow in areas where bone has gone missing due to accident or disease.