Several new AM materials were announced in past weeks.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

Evonik’s VESTAKEEP i4 3DF PEEK Filament

Evonik’s new PEEK filament is apparently the “world’s first implant-grade filament” that is made from high temperature PEEK material. I’m not sure that PEEK’s high temperature properties are useful for implants, but PEEK’s chemical resistance certainly would be.

Nanovia Flex B4C

Nanovia introduced a unique filament that has some very unusual properties. Flex B4C is an “enriched composite” that is able to absorb free neutrons, meaning it is suitable for use in some nuclear applications. It’s also able to withstand significant impacts, and has an operational maximum temperature of 70C. However, it’s quite expensive €499 (US$544) per 500g spool.

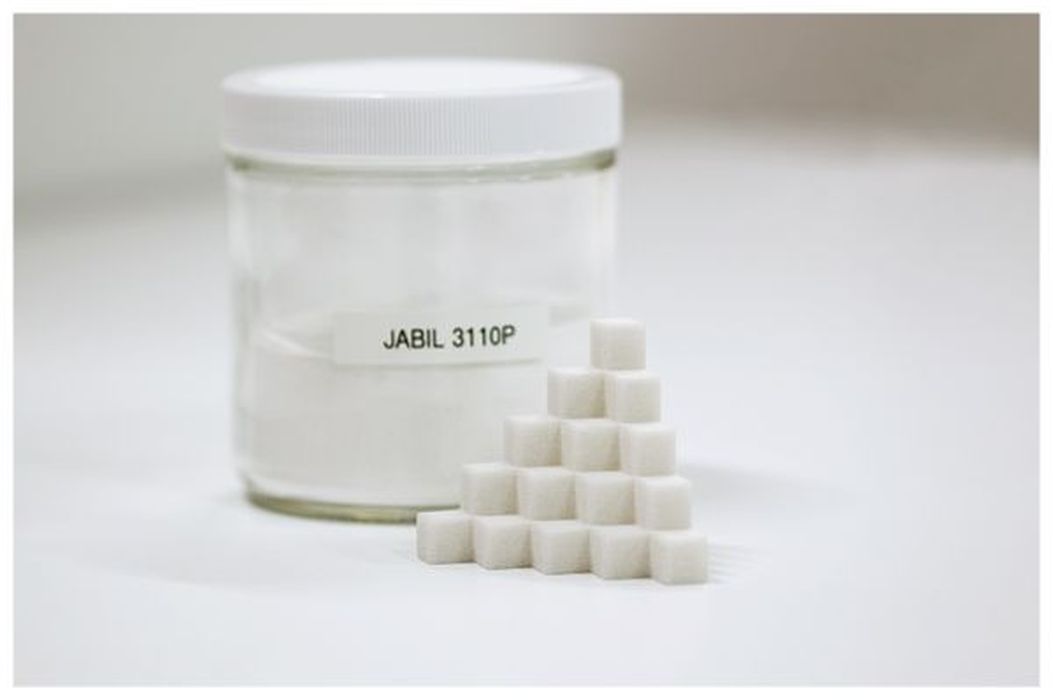

Jabil’s PLA 3110P

Well-known contract manufacturing service Jabil introduced a unique PLA powder for use in their SLS equipment. As far as I can tell, this is the only PLA powder used in any SLS systems.

Xtellar Sugar Cane Pellets

New 3D print materials provider Xtellar introduced a material never previously seen: EVA pellets, which are made from raw sugar cane. This is a flexible (89 Shore A) material that would be used in pellet-based 3D printing systems. The idea is to provide another sustainable, low-carbon option for 3D print materials.

Kimya ABS-R

Kimya introduced ABS-R, a recycled ABS material. Kimya sources the standard ABS from a recycling company in France, where the material is 100% post-consumer waste. ABS is an excellent candidate for recycling, and this product should help reduce the carbon footprint. This also might be one of the very few recycled ABS options on the market.

Liqcreate

Liqcreate’s new Bio-Med Clear resin is a rigid material that is non-cytotoxic, non-sensitizing and non-irritating. It can be used on most desktop resin 3D printers that use any light frequency between 385-420nm (most machines are 405nm). It’s also possible to sanitize parts printed with the material using disinfectants or high temperature steam methods.