Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

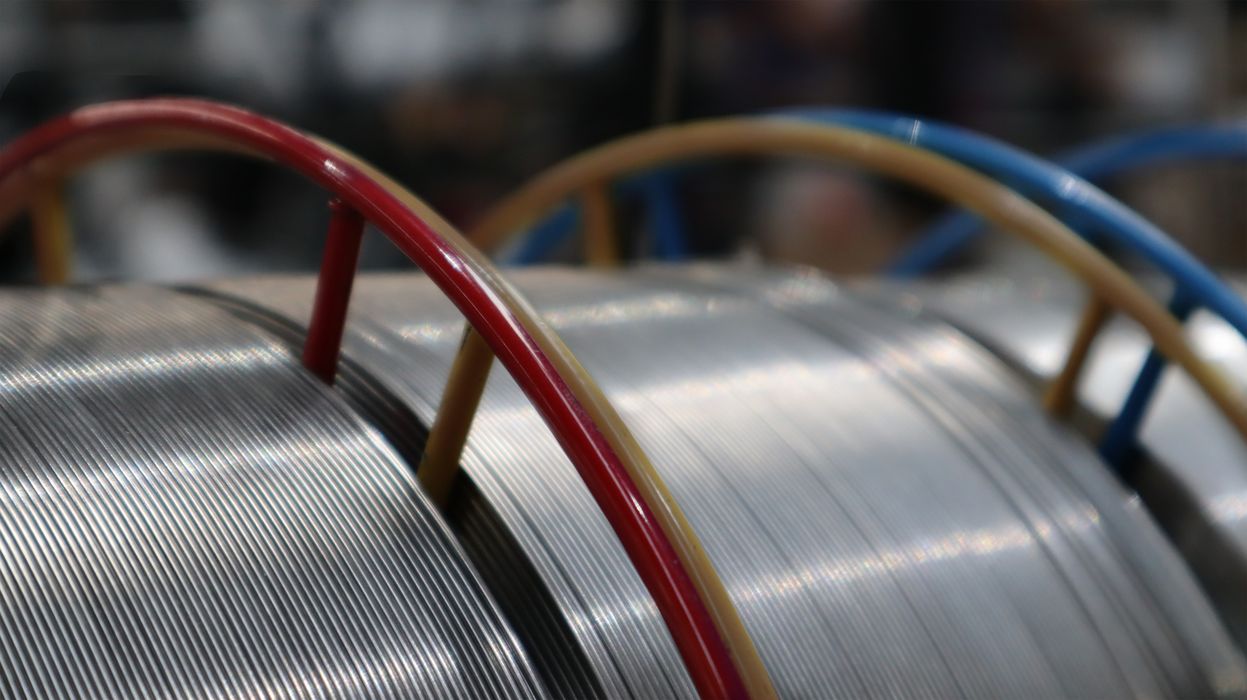

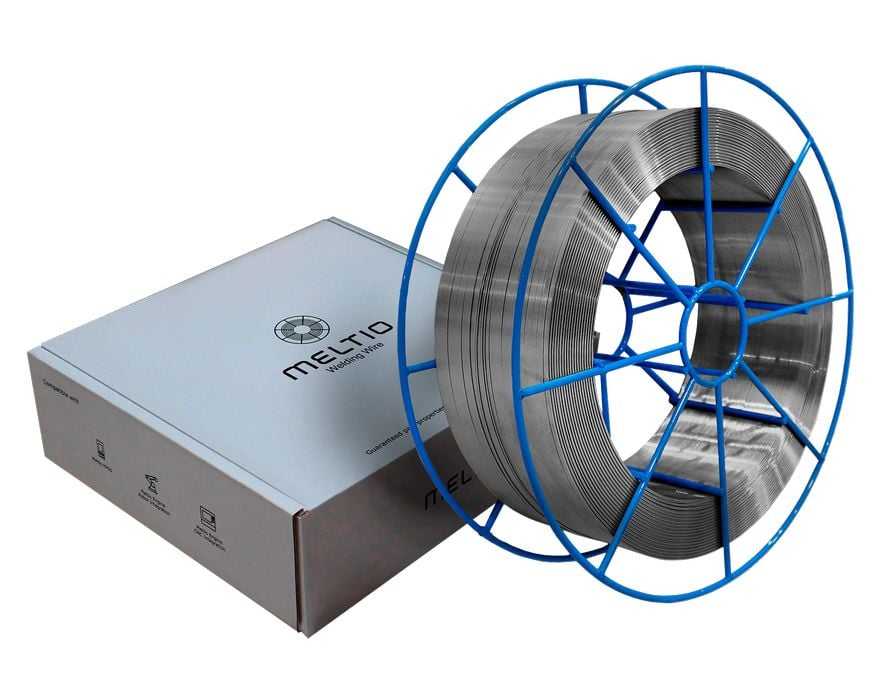

MELTIO Metals

MELTIO announced they’re introducing their own line of metal wire material for their DED 3D printing system. While the system has used commodity third party metal wire, they’re now offering own in addition. The materials in the MELTIO line include: Stainless Steel 316L, Stainless Steel 308L, Mild Steel ER70S, Titanium 64, and Nickel 718, and there are likely more to be added. The company also indicated they are working on enabling the use of refractory metals, such as copper and aluminum in the future.

This appears to be a way to provide a convenient source of materials for MELTIO clients, and a way the company can leverage their customer base for a bit more revenue.

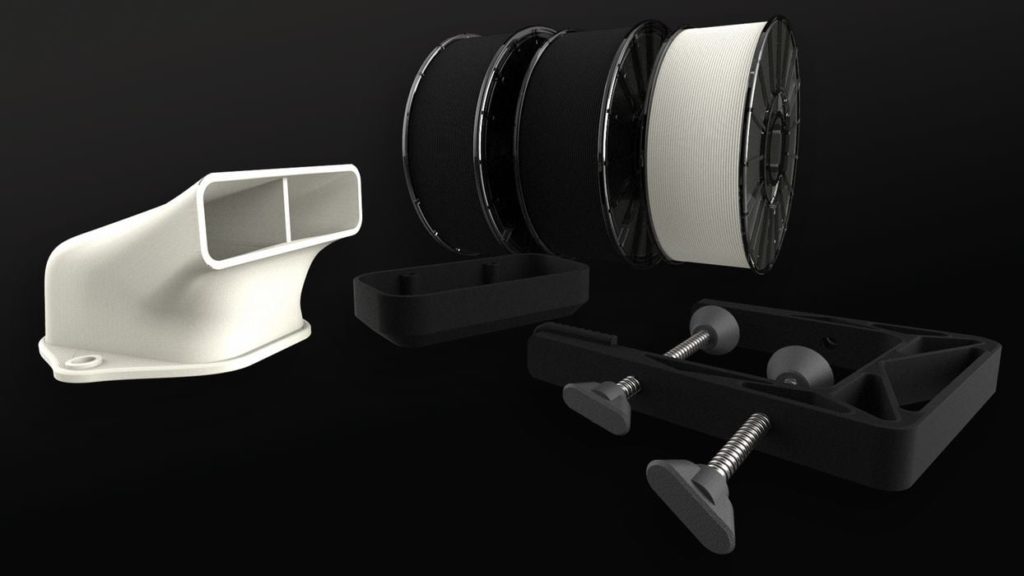

Recreus PETG-CF

Recreus announced a new PETG variant, this one with a mix of chopped carbon fiber. Their new PET-G-CF filament is said to have a breaking strength 5X higher than plain PETG material. Of course, you will have to use this filament in a FFF 3D printer equipped with a hardened nozzle to avoid nozzle wear.

Recreus offers the new PET-G-CF in two sizes, 750g for €40 (US$45) and a huge 2.5kg spool for €140 (US$160). This should be an excellent material for printing mechanical parts.

MakerBot Advanced Materials

MakerBot has been on a tear this year adding new materials to their list of METHOD-certified filaments. This time they’re introducing three new advanced LUVOCOM materials from provider LEHVOSS Group. The materials include:

- LUVOCOM 3F PAHT 9825 NT – A high-temperature polyamide material with continuous service temperature of up to 100°C and the strength of PA6. The material has 50% reduced water uptake and a 4X slower absorption rate compared to PA6. Low moisture absorption can help minimize printing issues as well as property changes of the printed part. This material is optimized for low warpage, high strength and impact resistance, and excellent surface finish for end-use parts, such as flanges and fixtures.

- LUVOCOM 3F PAHT CF 9891 BK – The carbon fiber (CF) filled grade of LUVOCOM 3F PAHT 9825 NT has even lower water uptake and good resistance against harsh chemicals like automotive fluids. The addition of carbon fiber strengthens the thermal and mechanical properties, and has a continued use of up to 150°C while retaining 50% of its mechanical properties. The material is suitable for high temperature environments such as automotive under-the-hood applications, such as housings or engine covers. In addition to its outstanding mechanical performance, the material is easy to print and does not warp.

- LUVOCOM 3F PET CF 9780 BK – A carbon fiber-filled polyethylene terephthalate (PET) material that is easy to print, with low warping, and exhibits a superb surface finish straight from the printer, reducing the need for post-processing. It provides high strength, elevated temperature resistance up to 120°C and chemical resistance outperforming PETG.

Photocentric Mechnano-enhanced Resin

Photocentric has partnered with Mechnano to produce a new ESD resin suitable for electronic applications. The new material involves a mix of microscopic carbon nanotubes, which carry away electricity. This new material should eliminate static discharge damage to electronics, and thus should be ideal for the production of electronics cases, robotic grippers or other applications where static electricity could be an issue.

CEO of Photocentric USA 3D Paul Anfinson said:

“We’re delighted to partner with Mechnano to deliver what we believe will be a terrific innovation for the electronics manufacturing industry when paired with our proficiency in resin development. Damage caused by ESD is a huge issue in this sector, and this solves a previous challenge when it came to additive manufacturing, with our nanoengineered resin not only strengthening the product but also imbuing the material with the necessary ESD properties. The strength of materials can be hindered or compromised by other ESD additives but not with Mechnano’s technology, so we have something truly unique here. The addition of carbon nanotubes (CNTs) opens up many more exciting applications for our additive manufacturing solutions.”