Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

colorFabb PHA

colorFabb continued their habit of introducing highly unusual 3D printing materials with the introduction of “allPHA”. As you might suspect, their new filament is made with 100% PolyHydroxyAlkanoates, or “PHA”. It’s a biomaterial created via fermentation, requiring no fossil fuels in production. It also has the unique ability to fully break down when exposed the environment over time. colorFabb said it leaves no microplastics, and that’s a very good thing.

The new material, which I suspect will be quite popular, is available from June 1st, but can be pre-ordered now.

BASF Ultracur3D EL 4000

BASF’s Forward AM unit announced a new flexible material, Ultracur3D EL 4000. They explain:

“Ultracur3D EL 4000 by Forward AM is the latest addition to our flexible and elastomeric resins. With its high hardness of Shore 90 A, it is at the high end of our portfolio, which now covers the whole spectrum from Shore 40 A to 90 A. Due to its superior strength, rebound and tear resistance, this material is perfectly suitable for applications such as footwear, bike saddles and cushioning pads.”

This is an important development in the company’s portfolio, as it allows manufacturers a complete selection of flexible materials that should apply to any application.

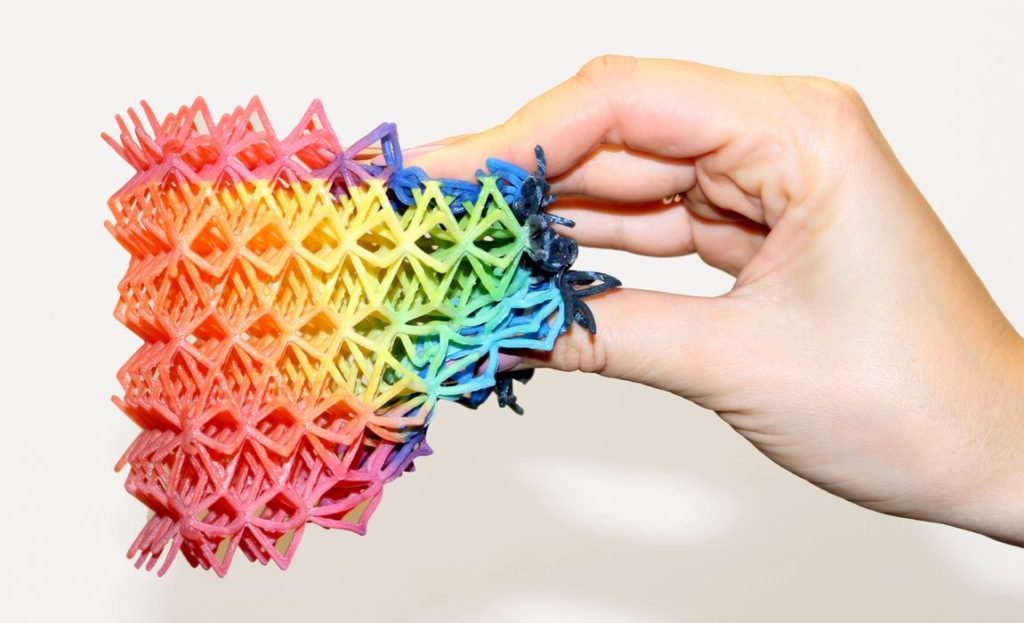

Stratasys Agilus30 Color Materials

Stratasys today introduced three new color resin materials for certain PolyJet devices, the J7 and J8 series. The new colors, each in the Agilus30 series, are cyan, magenta and yellow. Note those are the three base colors in the CMYK scheme, along with K (black).

Stratasys has essentially replaced their color base with this new Agilus30 trio that is said to reproduce lifelike colors in far more vibrance and realism. They explain:

“Full-color prototypes that look and feel like a final product are time-intensive, expensive and have previously been virtually unachievable. Agilus30 Colors takes the existing rigid materials and extends them to include flexible, full-color modeling capabilities with exact shore value definition ability. This allows designers to achieve full-color prints and prototypes that look, feel and flex like the final product, all of which are key to achieving designs with true realism.”

In other words, prints made from these colors will not only look lifelike, but they will FEEL lifelike as well. Note the flexibility shown in the images here.