Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

3D Systems Production-Grade Resin

3D Systems announced “Accura AMX Durable Natural”, said to be ideal for production of large scale parts on SLA systems. They explain:

“Accura AMX Durable Natural is a tough, production-grade resin with a unique combination of impact resistance, tear-strength, and elongation at break. Engineered to withstand repeated flexing, bending, and loading, AMX Durable Natural is ideal for cost-efficiently delivering durable parts with the high surface quality, accuracy, and repeatability advantages of stereolithography.”

Materialise Announces New Bio Material

Materialise announced the availability of “Ultrasint PA11”, a bio-based material from BASF’s Forward AM unit, which is apparently made from castor beans. Materialise has targeted this production-grade nylon material at the eyewear industry, where there is currently significant wastage of material due to the use of traditional manufacturing processes and the need to display many fashion styles that end up not being purchased.

The new material is certainly green, as Materialise explains:

“Ultrasint® PA11 is the latest addition to the eyewear materials portfolio at Materialise. The bio-based material is responsibly sourced from castor beans, based on Arkema Rilsan® Polyamide 11. Arkema develops advanced polyamide 11 materials, derived from consciously sourced plants without causing deforestation. The company, along with BASF 3D Printing Solutions, Jayant Agro-Organics and Solidaridad, is a founding member of the Pragati Initiative for sustainable castor bean farming in India, which has trained several thousand farmers on good agricultural and socio-economic practices.”

Two New Biocompatible Resins From Formlabs

Formlabs announced BioMed White Resin and BioMed Black Resin products to expand their biocompatible material portfolio. These join BioMed Amber, Elastic and BioMed Clear in the now-five item biocompatible catalog from Formlabs.

These resins are used on Formlabs equipment for a variety of healthcare and dental applications. Formlabs explains:

“BioMed Black and White are USP Class VI certified and provide high performance, sterilization compatibility, and long term stability, designed for applications where opaque materials are preferred for functionality or aesthetic quality.”

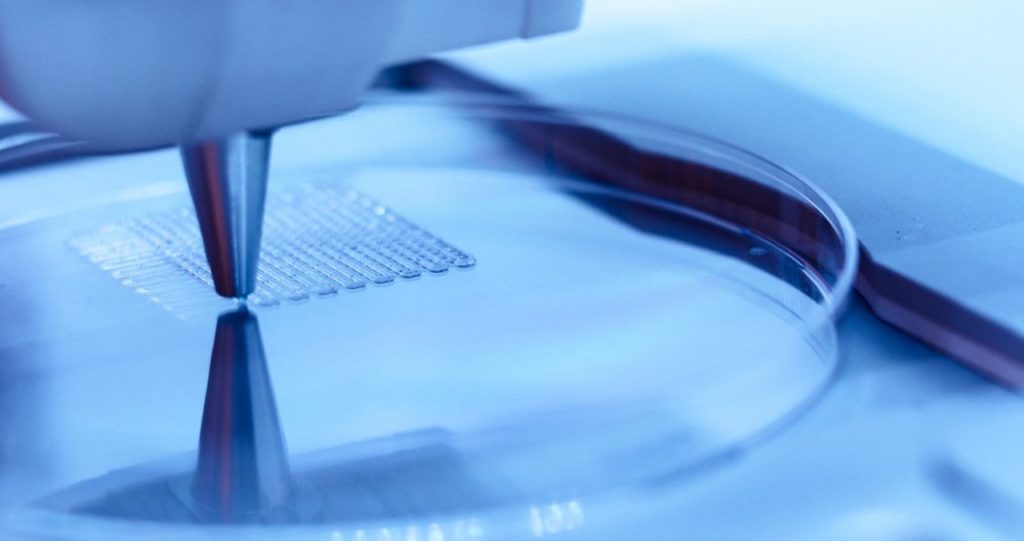

Startup “BIO INX” To Produce Bioprinting Materials

A spin off from the University of Ghent has incorporated and launched as “BIO INX”. The goal of the company is to produce advanced bioprinting materials.

Why do so? They explain:

“Cells as such are very difficult to process with a 3D printer, therefore, there is a need to combine these cells with suitable materials which not only make the cells printable, but also mimic the natural extracellular environment and keep the cells alive during the printing process. These materials are often referred to as bio inks.”

Hence the company’s name.

What materials are offered?

“The targeted printing technologies include deposition-based printing and light-based printing. For deposition-based printing where a construct is generated by depositing multiple layers of material on top of each other, it currently offers 5 different inks. For the high resolution laser based multiphoton lithography, it currently has 4 different inks, including the world’s only multiphoton lithography material allowing live cell encapsulation with printing resolutions down to 1 µm.”

Evidently they are working on DLP-capable biomaterials for a future release.