Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

SLM Solutions Case Hardening Steels

SLM Solutions announced one of their partners, Germany-based Burgmaier, had developed a technique for 3D printing with case-hardening steels, including 16MnCr5. This type of steel is often used for tool and mold making, as the material offers a very hard surface, yet can have a ductile core.

SLM Solutions explains:

“The introduction of case-hardening-steels to AM is a game changer: a new world of hard-wearing designs is now possible—from lightweight tools with flexible cooling channels to resistant and cost-efficient molds. The hybrid-manufacturing process includes an innovative, self-developed system to clamp various base bodies and a standardized approach to manufacture the parts additively in a SLM® 280, enabling single-use and series production with the highest accuracy. Burgmaier achieves a positioning and repeating accuracy of fewer than 0.05 millimeters and a high-quality joint of the base body and the AM part.”

Recreus Purifier Filaments

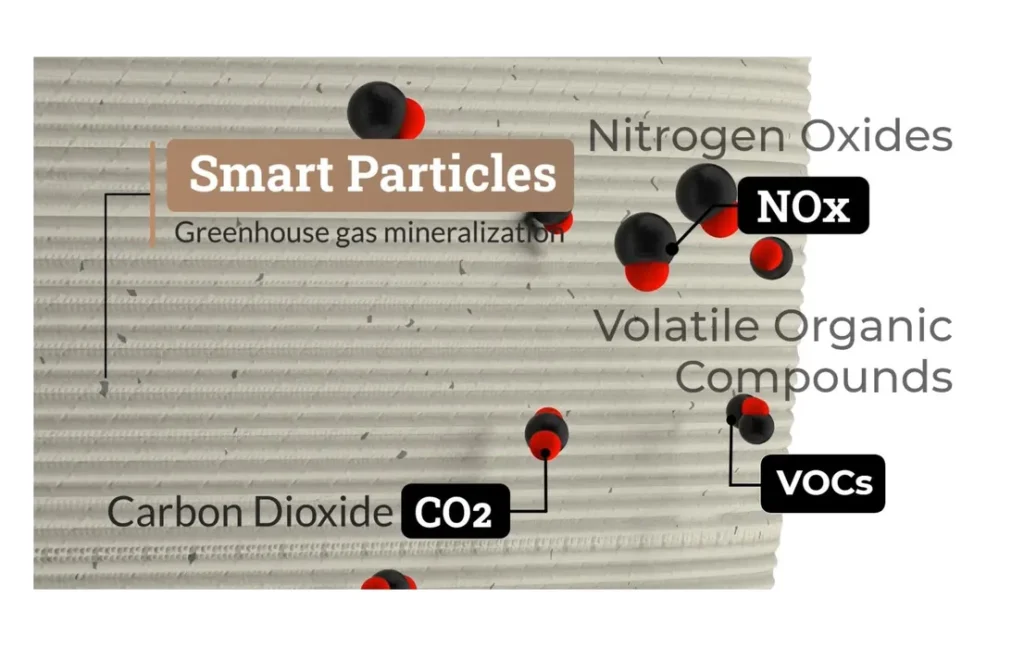

Recreus announced a new line of 3D printing filaments called “Purifier”, which apparently have “transformative properties”.

According to Recreus, the new Filaflex Purifier and PLA Purifier are able to remove noxious gases and particles from the air.

How does this work? It seems that the new materials contain “smart particles” that are able to absorb CO2, Nix and VOCs when exposed. Thus you will be able to 3D print objects that, as they rest in the atmosphere — and in sunlight, will slowly absorb small quantities of these noxious materials.

Recreus explained that the process is a combination of catalysis and photocatalysis. The “bad” molecules are transformed through these processes into calcium carbonate, magnesium carbonate and ferrous carbonate, all harmless substances.

This is a highly unusual material and I’m not quite sure of the applications. It might be possible to 3D print some sort of filtration apparatus that could take advantage of these properties, but success would depend on the volume of noxious particles that could be handled.

New Evonik INFINAM Resins

Evonik announced two new AM resins for their INFINAM line: FL 6300 and RG 3101 L.

RG 3101 Lresins is intended for use in both SLA and DLP 3D printing processes. They explain its benefits:

“The ready-to-use material combines excellent impact resistance with high temperature resistance while exhibiting long-lasting thermomechanical performance. 3D components printed from INFINAM RG 3101 L, such as drones, buckles, or automotive parts, can be processed by machine and remain fracture-resistant even when subjected to strong forces.”

Meanwhile, the other new material, FL 6300 L, is actually the product of a joint venture with Cubicure, another maker of speciality resins for additive manufacturing. They explain how this new resin can be used:

“The hot lithography printing process developed by Cubicure makes it possible for the first time to process highly viscous light-curing polyester-based resins. In contrast to conventional stereolithography, Hot Lithography creates objects at an elevated processing temperature using light-induced polymerization. The process allows a significantly wider range of processable components.

The result of this collaboration is the first industrially suitable elastomer from the photopolymer class. INFINAM® FL 6300 L enables the additive manufacturing of highly flexible 3D objects that excel in material properties essential for elastomers: in addition to outstanding low-temperature elasticity, its strengths include dynamic load cycles of up to one million load cycles.”

Both are powerful materials that will certainly be used for industrial applications.

Via SLM Solutions, Burgmaier, Recreus and Evonik