Researchers at ETH Zurich have developed a method of 3D printing with salt, which is being commercialized.

Salt is a ubiquitous material, one we are literally made from. Yet to date no one seems to have considered the use of it as a 3D print material.

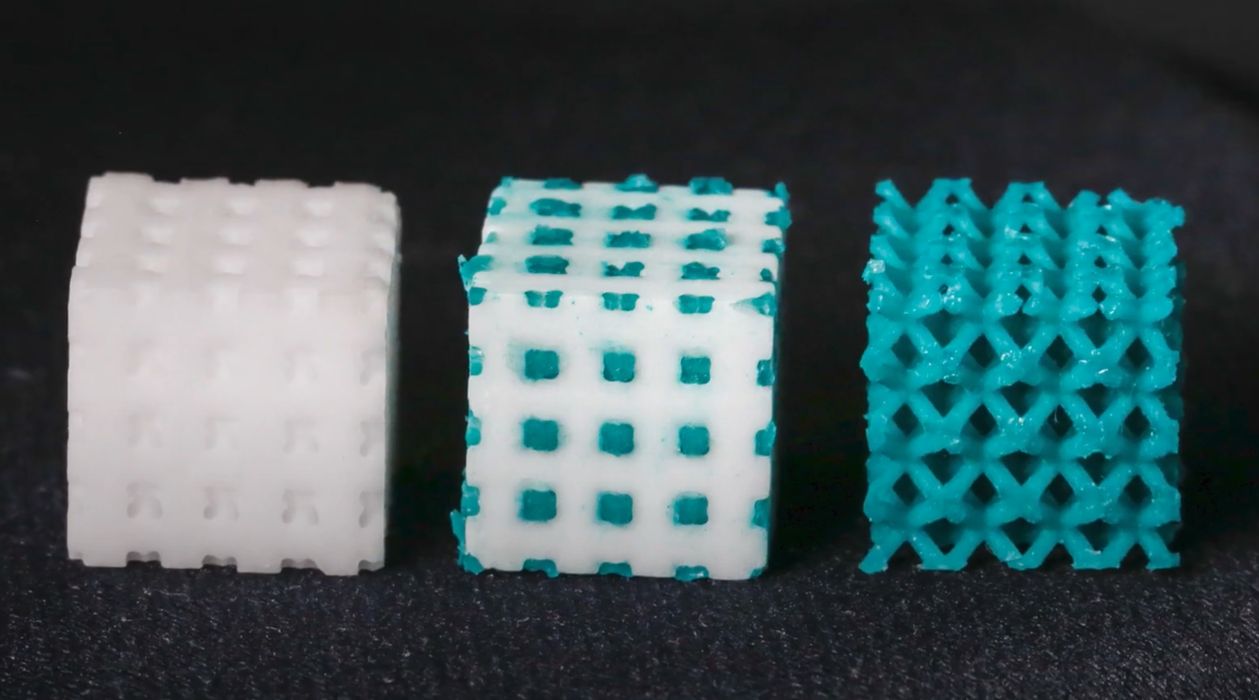

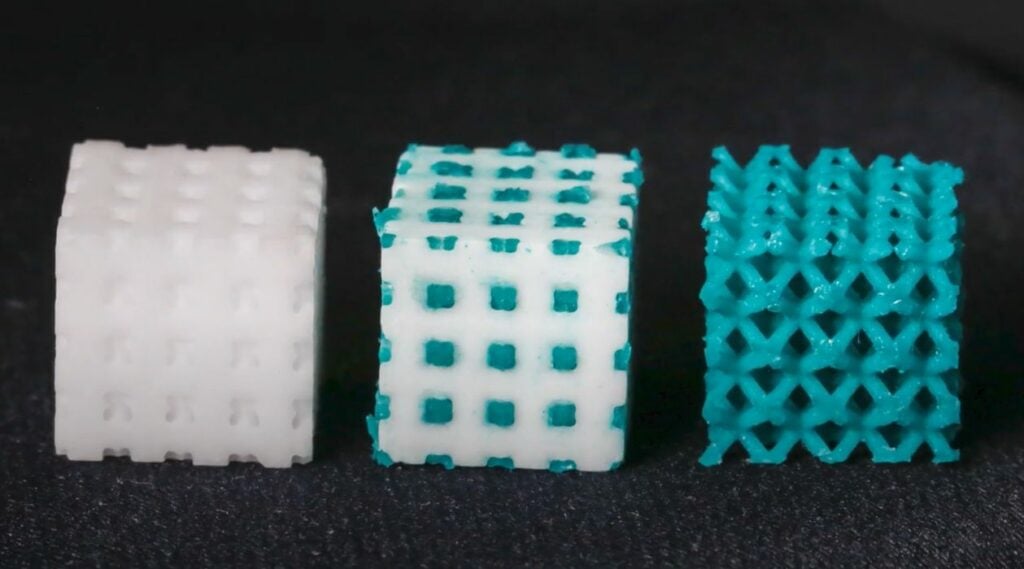

In a paper published earlier this year, researchers at ETH Zurich described a process by which complex molds could be 3D printed in salt.

The idea is to use a sacrificial mold, which is actually quite a common process in 3D printing. There are companies like ExOne and voxeljet that provide equipment to 3D print molds in sand, which are used to cast large metal objects. This is also done at nanoscale, by using two-photon 3D printing. However, those techniques don’t provide sufficient resolution for medium-scale objects. Worse, the removal of the mold can be difficult, and sometimes involves use of very high temperatures (400C) to degrade the material. That’s expensive.

The researchers referred to the new salt approach as a “universal” manufacturing platform, and I believe they may be on to something. Here’s how it works.

- A photopolymer resin is infused with fine NaCl (salt) particles

- A complex geometry is 3D printed using this resin, in the form of a negative mold

- The salt-resin print is heat-treated to remove the polymer

- The mold then undergoes a sintering process at 690C to fuse the remaining salt together into rigid form

- A wide variety of liquid materials can be cast into the mold

- After hardening the salt mold must be removed, and this is easily done with plain water!

There are multiple advantages to this approach, including:

- The cost of salt is negligible and is available everywhere

- Salt is non-toxic, meaning bio-materials could be cast and no extra safety procedures are required

- Water for mold removal is inexpensive and easily available

- The resulting salt water is non-toxic and can easily be disposed of

- Many different materials can be cast

The two ETH Zurich researchers, Nicole Kleger and Simona Fehlmann, intend on launching a startup company to exploit the new process. Their startup is to be called “Sallea”.

From the looks of their material, it seems they could be 3D printing molds to make objects from metals, composites, polymers and even food.

The process used by Sallea seems quite reminiscent of that of AddiFab, which uses polymer resin 3D printing to produce complex sacrificial molds. However, the Sallea salt process could prove less expensive.

Via Wiley, 3D Grenzenlos (Deutsch), ChemEurope and Sallea (Hat tip to Benjamin)