A new 3D print material made from oranges has been used in an artistic project.

Italian design studio Krill Design produced a 3D printed lamp called “Ohmie” made with the unusual custom material. The studio is well-known for its previous ventures that have made use of material that would otherwise have been trashed.

The new biopolymer is not made from the entire orange, but just the peels.

The process is to dry Sicilian orange peels and then pulverize them into a powder. This powder is then mixed with a starch base to form pellets. These, in turn, are extruded using standard equipment into filament form on spools.

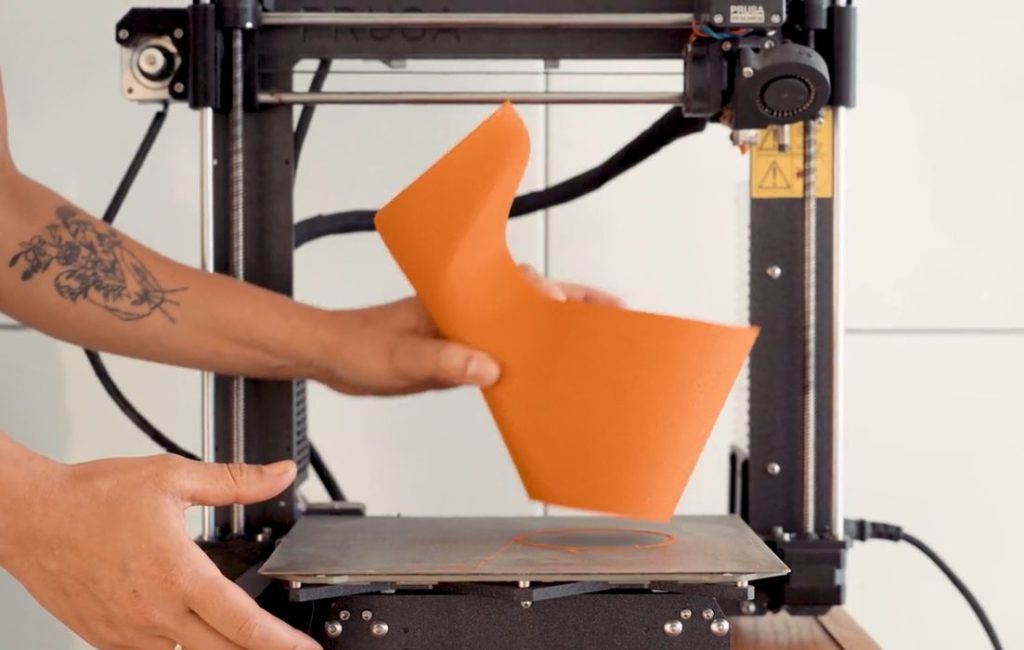

Then the Ohmie can be 3D printed. From their Kickstarter video, it appears they used Prusa equipment to do so.

The use of organics in 3D printer materials is not new. We’ve previously seen composite polymers made coconut shells, bamboo, certainly wood fiber, algae and coffee. And, yes, we’ve seen orange peels used. It’s a straightforward matter of mixing powder and polymer together in a suitable ratio.

These composite materials were popular in the past, not for their engineering properties, but instead for the sheer novelty of using them. Imagine the fun, for example, of 3D printing a tiny coffee table made from coffee!

In recent years interest in this approach has waned, but it seems that Krill Design has revived the approach, at least for this project.

What’s interesting about the Ohmie design is that Krill Design have leveraged the normally unattractive layer lines produced by the FFF production process. The texture formed by the extrusions actually fits very well with the shape and makes it far warmer than you’d get from a simple injection molded object.

The Ohmie is still available on Kickstarter if you wish to purchase one. It’s priced at €72 (US$85) and actually looks pretty good.

Via Krill Design, Kickstarter and Colossal (Hat tip to Pete)