At least two companies plan to produce 3D printed chamois pads.

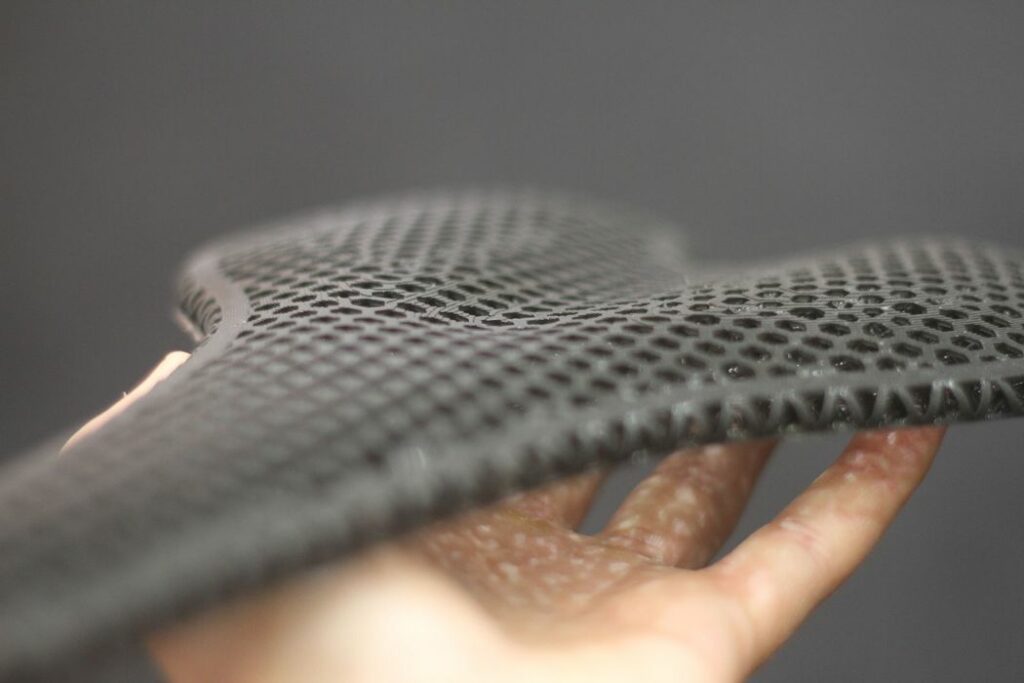

I have a suspicion most Fabbaloo readers have no clue what a chamois pad might be. It’s in fact that spongy piece found on the inside of bike shorts that provides padding for the rider. Chamois pads are especially welcome for long rides where there’s plenty of pressure and abrasion potential.

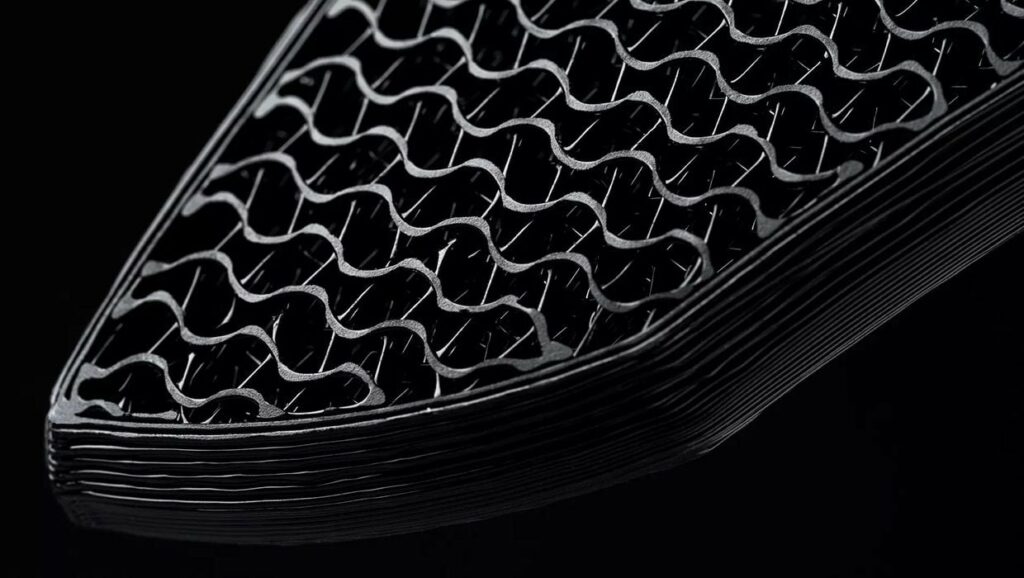

Companies like Carbon in particular have designed their hardware and software to produce complex lattice systems that have been used for a variety of sports gear, typically for components absorbing forces, like helmets, midsoles and seats. Lattice structures cannot be easily manufactured using conventional processes, but are no problem for 3D printing approaches.

At least two companies are now planning to manufacture chamois pads for bike shorts: Elastic Interface, a long time B2B provider of pads, and Endura, who displayed a 3D printed chamois pads at a recent trade event.

The chamois pad provides the physical interface between the bike seat and, well, the rider’s bottom. It’s critical to get this correct, as long cycling rides can amplify the slightest problem from annoying to catastrophic.

Elastic Interface 3D Printed Pads

Elastic Interface is a B2B company that produces the pads for installation into bike shorts by apparel manufacturers. They’ve been around for many years, and have a large selection of products. Is there a one best pad? Not really, as they explain:

“There isn’t an absolute best cycling pad. There is the best cycling pad for your needs: it all depends on discipline, duration of ride, gender…”

As such they market a variety of different pad products to meet general market demands.

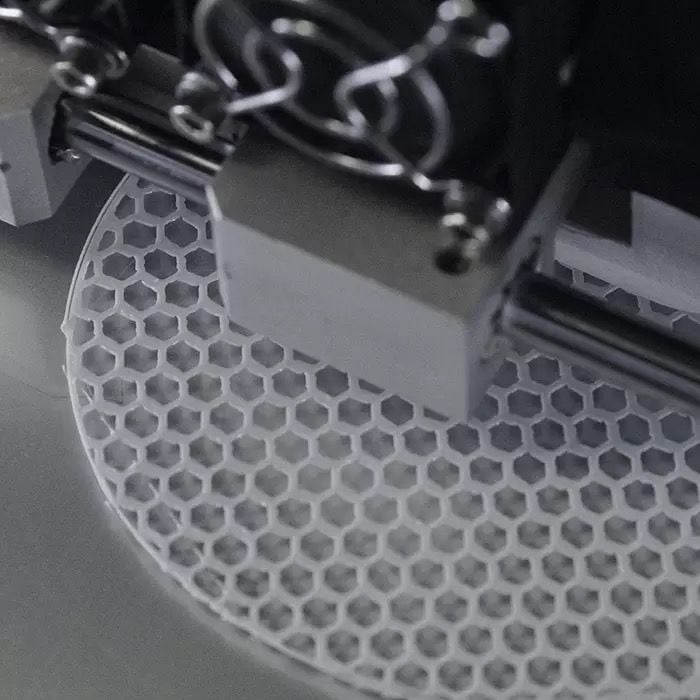

However, Elastic Interface has developed what they call “N3X: The third dimension in comfort”. This is a hexagonal structure that’s inserted into the pad that provides additional benefits, including:

- Complete freedom of movement

- Enhanced stability

- Comfort

- Enhanced air permeability and breathability

- Quick drying

- Moisture management

- Differentiated areas of support

- Prevents bacterial proliferation

And, most importantly, is “100% customizable”. This takes advantage of 3D printing’s ability to print different geometries at the touch of a button. While this might not be leveraged at the individual basis, it’s possible for Elastic Interfaces’ B2B clients to order precisely what they need.

It’s not clear what specific 3D print technology is used by Elastic Interface, but from the looks of the prints, it would appear to be an FFF process.

Endura 3D Printed Pads

Another company working on 3D printed chamois pads is Endura. They’ve partnered with Carbon to produce a pad that will supposedly show up in 2023 in the company’s Professional SL 3D Matrix EGM Bibshort product.

Carbon has focused much of their advanced 3D printing technology towards applications that involve complex lattices. In the past they have worked with shoe manufacturers to produce highly sophisticated midsoles that actually provide more power for runners through an ingenious configuration of varying strength lattice zones.

Carbon is able to do this with the use of their now-open-for use 3D CAD design software, Design Engine. This software can easily create such complex lattice configurations, which are typically near impossible to produce using conventional CAD tools.

This capability has enabled Carbon’s clients to produce not only midsoles, but high performance sports helmets, bike seats and much more.

What we’re seeing here is companies now mass adopting 3D print technology for a new type of product. It may be that those still producing old-style products in this area might soon be forced by the market to switch to additive processes as well.

Via Cycling News, Carbon, Elastic Interface and Endura