Nanoscribe announced a new feature for their ultra high resolution 3D printer that could put them in competition with SLA 3D printers.

For many years the world of nanoprinting was quite separate from conventional 3D printing of mechanical parts. Nanoprinting is a technology that allows production of extremely small objects with great precision. Normally this is done using the two-photon printing process, which has been adopted by several nanoprinting players.

One of those players is Nanoscribe, a German company that produces the Quantum X, a device capable of producing objects with features as small as 100nm in size. (Note: 100nm is 1000x smaller than the typical FFF 3D print layer size of 0.1mm).

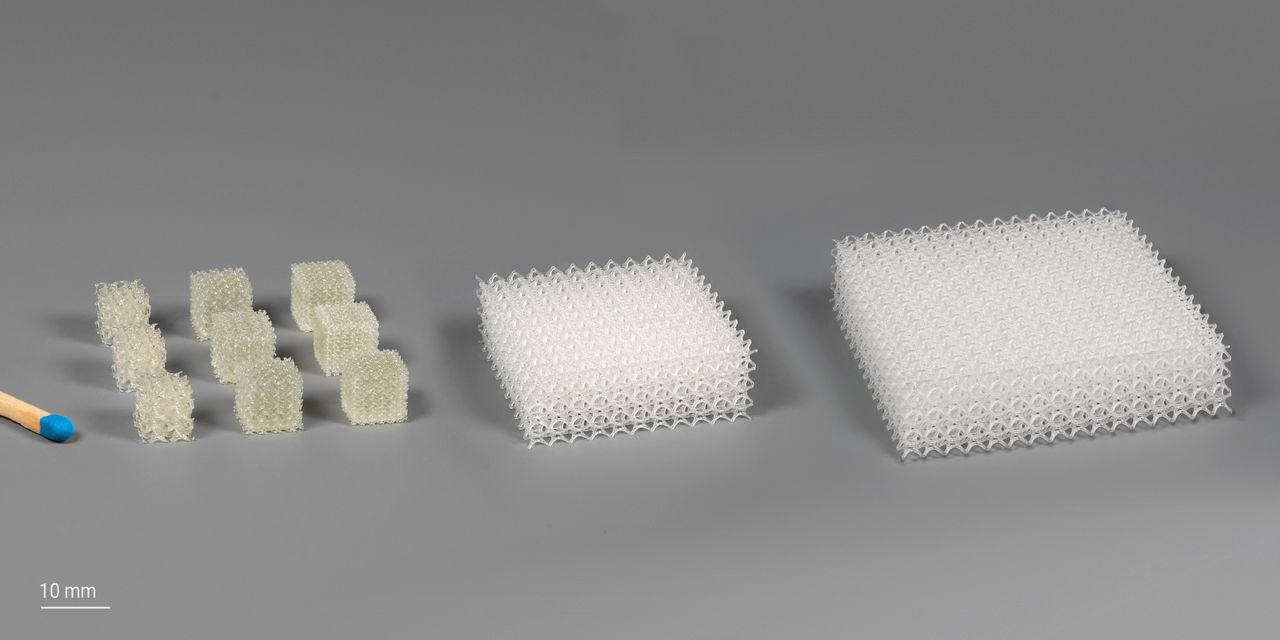

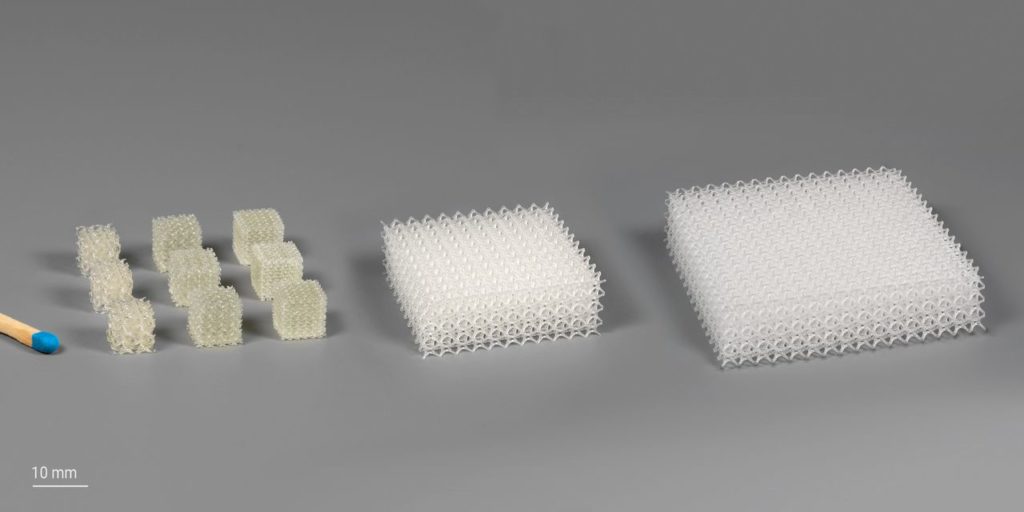

Because of the extremely small details possible with this technology, the normal approach has been to produce very tiny objects. Items such as complex optical elements, filtration components or other finely detailed objects were produced. However, the size of these objects resulted in a build volume measuring only a few millimeters across.

That is to change with Nanoscribe’s introduction of their new Extra Large Features Print Set for the Quantum X, or “XLF”. Nanoscribe explains:

“With the XLF Print Set, the high-precision 3D printing technology can now be seamlessly extended to centimeter-sized objects, with precision typically 2 to 5 times higher than comparable microfabrication technologies. In a single pass, objects up to 30 cubic centimeters can be produced.”

Now, 30 cubic centimeters is not exactly “large” as many would consider: that is a cube about 31mm on each side. However, in the nanoprinting world, that is a gigantic size.

Nanoscribe also said:

”Combined with a high scanning speed, adjustable voxel sizes, and a highly sensitive photopolymer resin, the XLF Print Set provides a comprehensive solution for high-precision 3D printing in the milli- and centimeter range. It is therefore an attractive solution for prototyping and manufacturing, for example, mechanical parts such as millimeter-sized connectors and housings, microfluidic structures, and scaffolds for biomedical research.”

The added build volume can also be used to increase throughput very significantly: more smaller objects can be produced in each print job.

The build volume appears to be near 50 x 50 x 10 mm. This is smaller than even jewelry 3D printers, but certainly vastly larger than the previous build volumes.

This is a very interesting development, because it may lead to a future where Nanoscribe’s XLF technology may collide with high resolution SLA systems that operate in the same or slightly larger build volumes.

But would those operating jewelry-sized 3D printers need the added resolution? Many of the details made possible by nanoprinting would not even be visible to the eye.

My thought is that the added build volume will eventually provoke the development of a new class of parts that leverage the huge build volume. Think of highly complex, multistage filters, or smart fluidic devices.

Or, more likely, something entirely new because this 3D printing capability didn’t exist before.

But it does now.

Via Nanoscribe