Nanoe is one of several companies providing specialized 3D printer filaments.

The 16-year old French company has been producing nanopowders for the ceramic industry for many years. In 2018 they introduced their Zetamix line of 3D printing filaments.

The Zetamix line includes filaments with both ceramic and metal powder mixes.

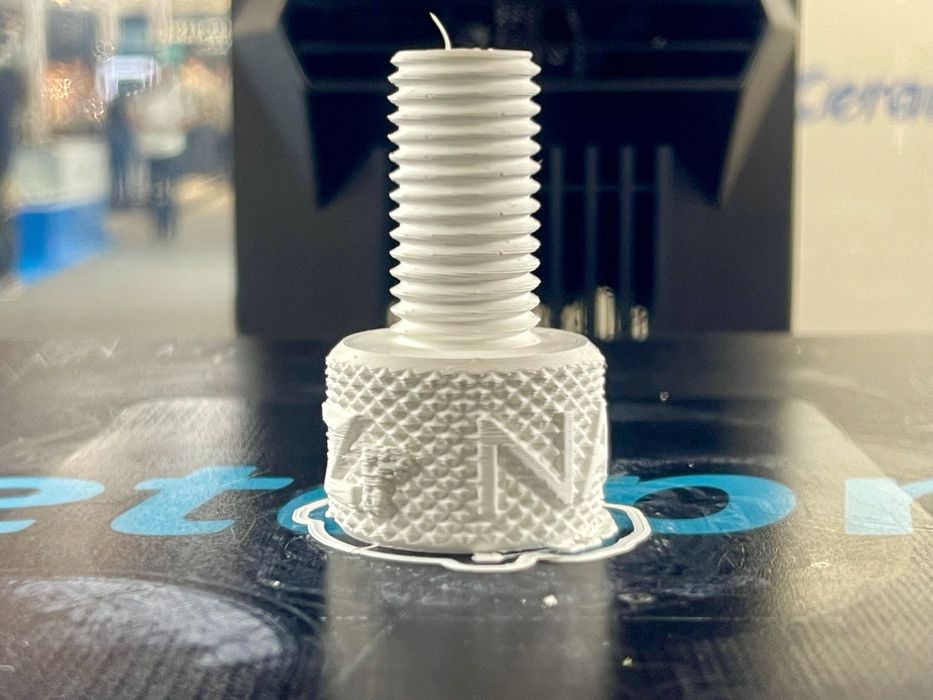

Producing objects with Zetamix filaments requires a few steps. First, the object is 3D printed in the usual fashion on most FFF 3D printers. Then the polymer component is removed with an application of acetone, and finally the remaining ceramic (or metal) particles are sintered together in an oven. The heating process involves a specific thermal profile for optimal results.

The resulting parts have a 99% density, meaning they are basically metal or ceramic parts — even though they were printed from filament.

Currently there are a number of materials available:

- White Zirconia

- Black Zirconia

- Alumina

- 316L Stainless Steel

- H13 Steel

- Porcelain

- Silicon Carbide

There’s also an intriguing product called “Zetamix filament Ɛ” (for “Epsilon), which apparently does not require debinding or sintering. Nanoe explains:

“The Zetamix Ɛ line includes 3 filaments with different permittivities: 2.2, 4.5 and 7.5. These products benefit from very low dielectric losses and heat resistance of up to 110 degrees Celsius.

These filaments can be used to produce components for the radio frequency field, in particular antennas or radars.”

I asked whether there are any special requirements for FFF 3D printers in order to use these filaments, and was told there were not, aside from recommending direct extruders rather than Bowden extruders. In fact, the materials adhere to standard build plates easily, and 3D printing them is straightforward. Nanoe themselves resell a stock Raise3D 3D printer model specifically for use with their filaments.

They do say that the materials are abrasive and recommend changing nozzles every two spools printed. This very likely refers to standard brass nozzles that are quite soft. It may be hardened nozzles would last far longer.

The only catch is that you must have an appropriate sintering oven to execute the required post processing steps. They specifically suggest using a sintering oven capable of using hydrogenated argon (Ar + H2 2.4%), so you’re not going to use a basic sintering furnace.

They also suggest using print speeds of 25-40mm/s, which is far lower than the usual high speeds of today’s desktop devices. However, other materials like TPU also require slower print speeds.

Note that these are premium industrial materials and thus carry premium prices. You’re not going to get a spool of ceramic filament for US$22.

Nanoe mentioned they are seeking resellers in North America. If you happen to be a reseller and want to sell a new line of advanced filaments, you should contact Nanoe.

If you’re interested in 3D printing with unusual ceramics and metals on an FFF 3D printer, and in particular are 3D printing antenna parts, you might want to consider looking at Nanoe’s Zetamix line of 3D printer materials.