Nano Dimension announced a partnership with XPTL to develop a new conductive ink for their systems that is based on nanoparticles.

Nano Dimension is a manufacturer of specialized 3D printers for the electronics industry. Using their DragonFly system one can 3D print complex circuit boards in ways that cannot be achieved easily using conventional means. The “3” in 3D is not particularly prominent, as the DragonFly’s Z-axis is only three millimeters thick. However, that’s more than enough to enable the printing of multi-layer circuit boards. We track Nano Dimension each week on our leaderboard of 3D print companies.

XTPL is a Polish company that develops concentrated silver inks with nanoparticles for a variety of industrial applications, including semiconductors, visual displays, biosensors, anti-counterfeiting and PCBs.

Nano Dimension said:

“Nano Dimension and XTPL will focus on the development of new nano-particle conductive ink for AME [Additively Manufactured Electronics] applications, enabling high conductivity and high-performance material suitable for 3D electronic printing technology for ultra-precise delivery of nanomaterials.”

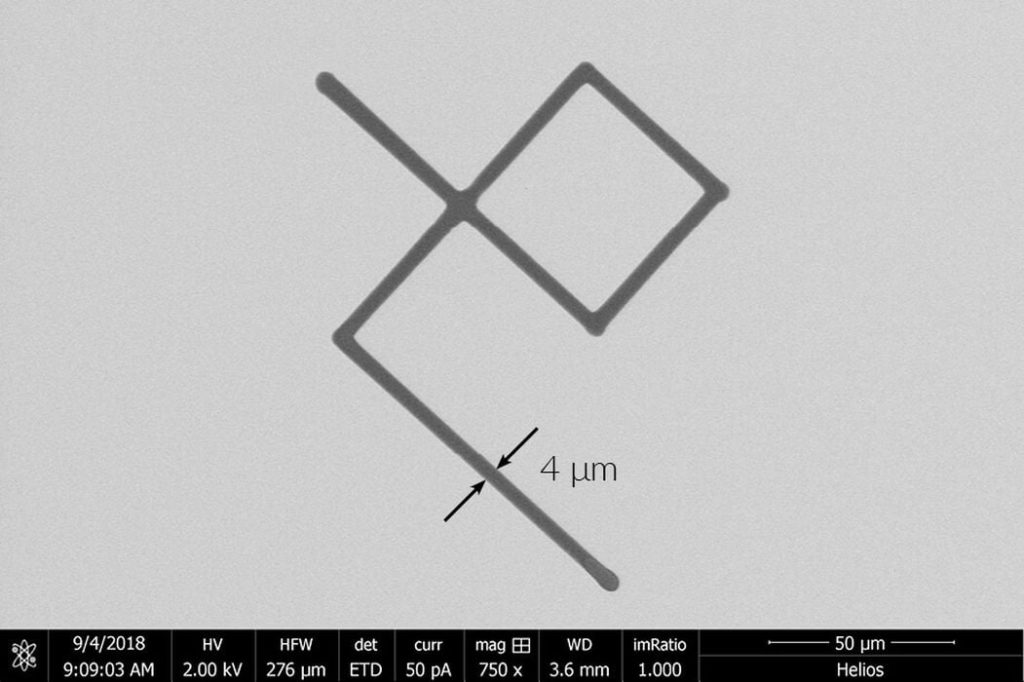

Apparently XTPL’s inks are entirely suitable for use in 3D printing, and can provide a resolution smaller than one micrometer (0.001mm) if dispensed by suitable equipment.

Here is an example of XTPL material deposition, at an incredibly small scale:

Chief Product Officer of Nano Dimension Hanan Gino said:

“Adding new materials to our portfolio is a key strategic aim for Nano Dimension. In addition to in-house development of dielectric and conductive ink, we partner with material companies to expand our material portfolio for different applications. The expertise of XTPL will enable our customers to more easily develop new classes of High-Performance Electronic Devices (Hi-PEDs) on our AME intelligent systems combining software, hardware, deep/machine learning, and materials for advanced industrial solutions.”

In other words, this new material should supercharge DragonFly operators’ ability to create unique PCBs with the system. It’s possible the XTPL material and technology could provide much higher resolution for PCB structures, and thus the size of PCBs could be decreased, or alternatively made more complex within the same space.

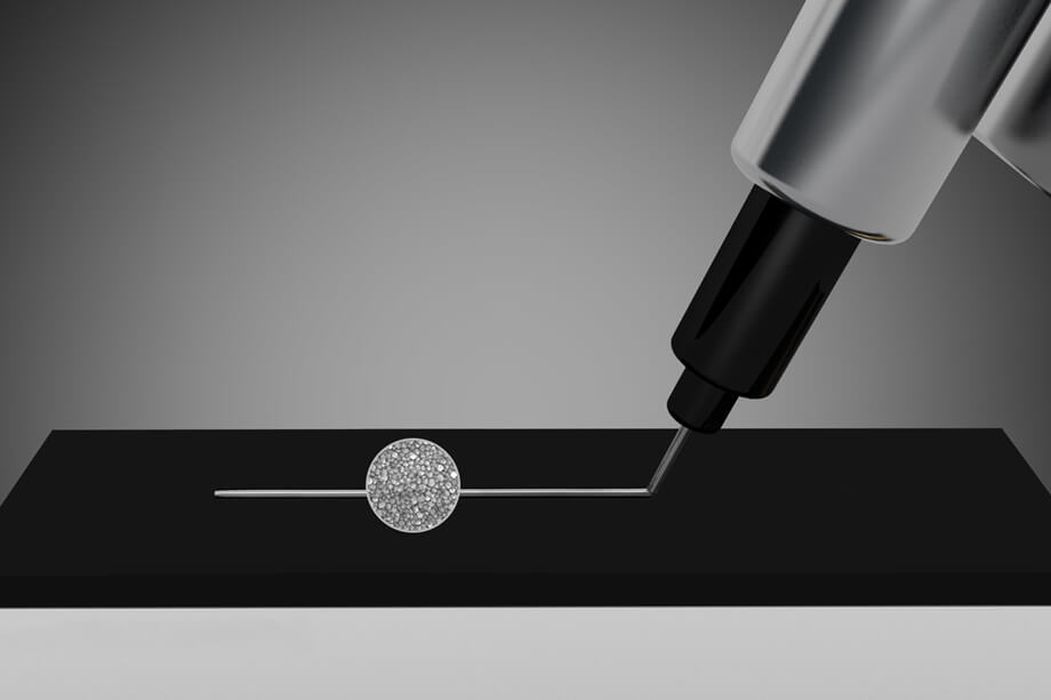

However, there may be hardware changes necessary for this to take place. According to XTPL’s website, the company uses a proprietary printing head and dispensing technology they call “UPD”, or ultraprecise dispensing technology. UPD can deposit in lines as well as single dots with varying widths.

It may be that future DragonFly equipment may have to somehow incorporate UPD tech into the printhead assembly, and that is likely the focus of the two companies’ work together.

It should be interesting to see if this announcement buoys the company’s valuation by the end of the week.

Via Nano Dimension and XTPL