Charles R. Goulding and Preeti Sulibhavi look at the use of 3D printing in the battle against myopia.

In a recent article in the Atlantic, the topic of nearsightedness, or myopia, was put front and center. While it may not have immediate political, economic, or social applications, it was an eye-opener, so-to-speak.

In the early 2000s, approximately 42 percent of 12-to-54- year-olds were considered nearsighted. That ratio was up 25 percent from the 1970s. And, by 2050, it is estimated that half of the global population will be myopic.

The amount of screen time children and adults spend is alarming and is the obvious culprit in this global myopia trend. Whether it is playing Minecraft on an iPad or scrutinizing voluminous data on a laptop, there are no limits to what could be causing this disturbing trend.

Eyewear and 3D Printing

We have written about various eyewear companies like Marcolin and Luxottica. We have even written about 3D printing AR contact lenses. But this issue goes beyond corrective options, it addresses the underlying issue of myopia. Companies are viewing this global myopic trend as something they can cash in on.

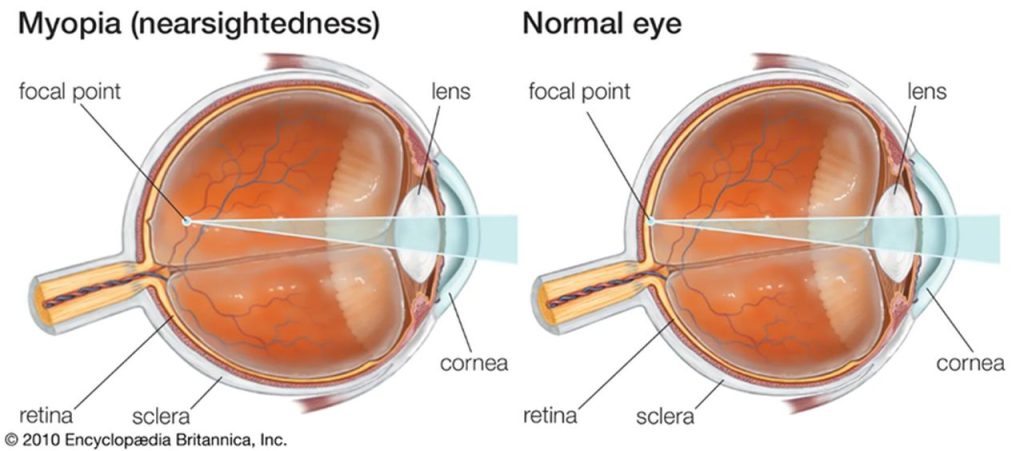

CooperVision and Bausch and Lomb are seeking FDA approval for new lenses that tweak how light enters the eye and produce a signal for the eyeball to stop lengthening. There is an alternative to lenses, which is eyedrops containing atropine, or a generic version of it. Atropine chemically alters the growth pathway of the eye when used at low doses thereby reducing the progression of myopia. There are also US trials in which eyeglasses can tweak how light enters the eye in order to slow its growth. Canada and Europe have already allowed these to be sold.

There are 3D printed contact lenses that are being investigated for functions in addition to corrective purposes. Researchers in India are using 3D printed, self-moisturizing contact lenses as medical devices. 3D printing lenses accomplish two goals: improving self-moisturizing capabilities of lenses and providing a platform for the future development of lenses with lab-on-a-chip capabilities, lending these lenses to work as functional real-time biomarker probing medical devices.

Companies using 3D printing to test and develop new and improved contact lenses are in good standing to take advantage of R&D Tax Credits.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Nothing “Corne-a’bout” This

Myopia is an issue that affects so many people, albeit to varying degrees. The forecast of one in every two people being afflicted by this disease should not be, and is not, taken lightly. Major multinational eye-care companies are vying for FDA approval to help resolve this condition and to economically improve their bottom lines. The 3D printing industry should not be myopic about this opportunity.