MX3D announced a new installation of the WAAM system that signals the company’s growth.

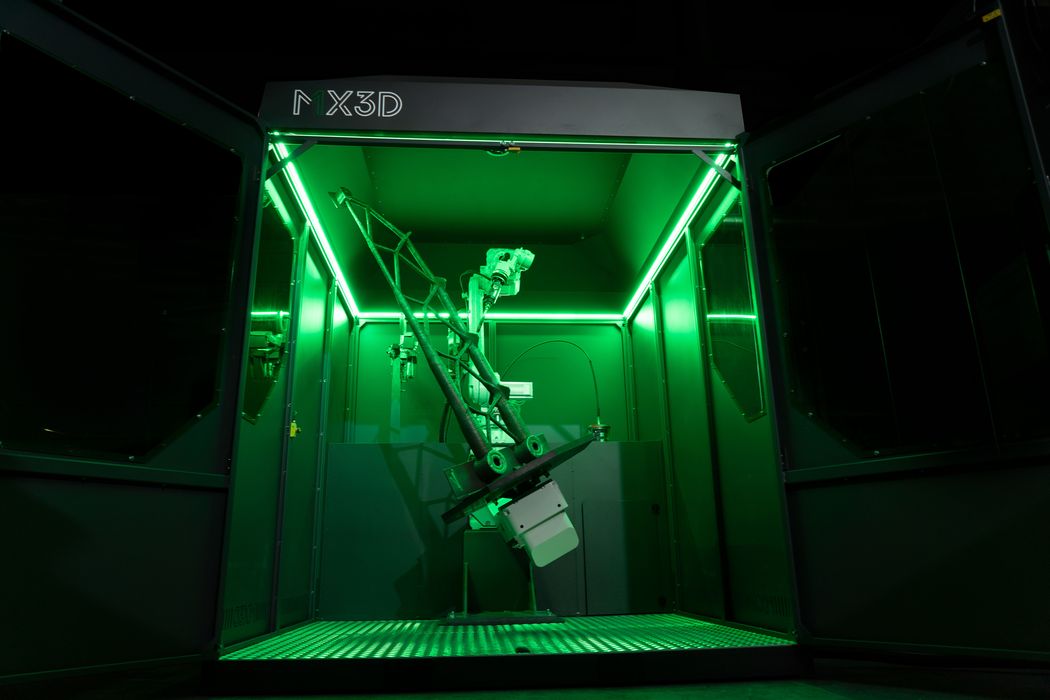

The company, based in Amsterdam, produces a WAAM 3D printing system: Wire Arc Additive Manufacturing. WAAM involves extruding a metal wire into a high-temperature electrical arc to instantly melt the material. The liquid then drops and solidifies. MX3D has mounted one of these print heads on a robotic arm, which moves around in 3D space to gradually deposit metal and form fully solid 3D objects.

The WAAM 3D printing process is relatively fast, but produces somewhat coarse output as compared to LPBF systems, but they are vastly more expensive to operate.

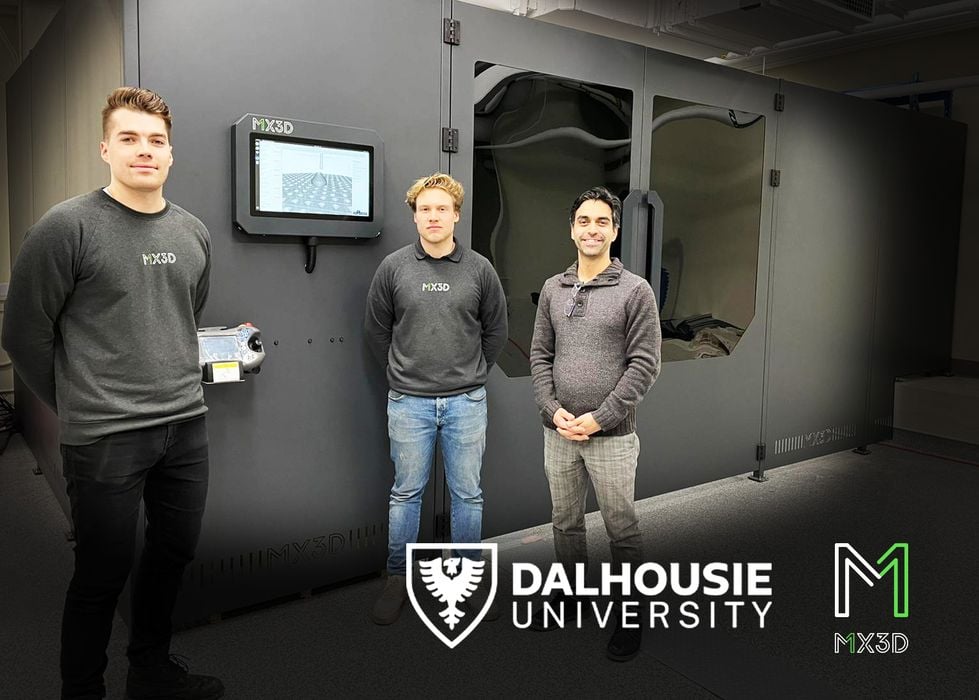

The news is that MX3D has installed their first M1 WAAM system in Canada, located at Dalhousie University near Halifax.

The intention of this installation is to provide a base for scholarly research into WAAM technology and methods, as well as offering the opportunity for innovation projects to make use of the technology.

MX3D explained the expected use of the M1:

“Their upcoming WAAM projects, including the manufacturing of R&D for the major architecture, engineering, and construction industries, are to follow their successful setup and orientation projects with MX3D. They will also use the technology for development testing on materials for components within manufacturing industries. Dalhousie is now at present, employing this technology and related applications for additive manufacturing from March 2023 onwards in Nova Scotia.”

Dalhousie University Professor Ali Nasiri explained:

“Our institute’s researchers and I are eager to observe how the manufacturing sector in Canada across multiple industries respond to this new technology. With metal additive manufacturing becoming increasingly popular in various industries, it’s crucial that we develop cutting-edge methods for testing and monitoring to fully unlock its potential.”

While the sale of a single machine is not normally a highly newsworthy event, this is a big deal for MX3D. It demonstrates their ability to service customers in locations distant from their Netherlands HQ, and thus opens the possibility of additional sales in similar regions.

In addition, the M1 at Dalhousie University will be viewed by students and others, who all will become familiar with WAAM technology. As they graduate and pass into the workplace, they just might find opportunities for using WAAM in other locations and situations.

This is a good move by MX3D.

Via MX3D