Charles R. Goulding and Preeti Sulibhavi consider the use of new 3D printed parts versus those from OEM inventory as airplanes again require more spare parts.

The pandemic caused planes of all ages to be put in storage and many of them at that. Planes that are at the end of their useful life are considered scrap but may be retained for replacement parts. In recent years, more and more 3D printed aircraft parts have been certified for both original equipment manufacturer (OEM) and replacement parts. Most car owners are familiar with the concept that certified used parts may be substantially less expensive than a brand new part. In fact, the used airplane parts business is estimated to be a $3 billion sales industry. Millions of Americans were introduced to the concept of large airplane graveyards in the great classic movie, The Best Years of Our Lives.

Currently, aircraft parts prices are low because many planes are grounded and replacement parts aren’t in demand. However, the travel industry is rapidly recovering and, presumably, the airplane parts and components industry will steadily recover as well. The travel industry data shows a record level of air travel reservations since COVID-19, however we have not yet returned to the record level of 2019 airline reservations. Only 440 large body planes were scrapped in 2020, down 15% from 2019.

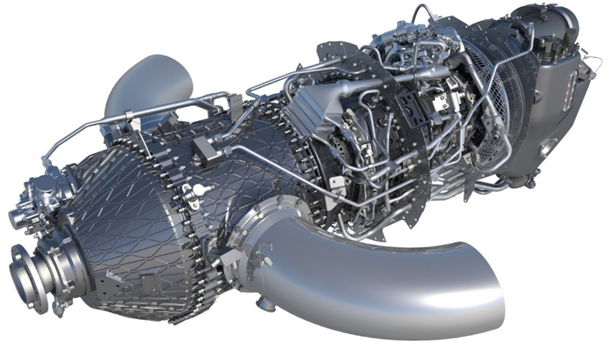

In theory, this means that as the industry recovers, fewer used parts should be available which should expand the market for certified 3D printed parts. When deciding between used parts and new 3D printed parts, it is important to also consider 3D topology design improvements and integrated parts. A new 3D printed part may be designed better and may integrate multiple parts into an improved seamless component.

It is important to remember that the replacement part/component will be functioning in unison with other parts. The quality of the replacement part will be improved by utilizing additively manufactured components that are often more durable with less weight.

It is helpful to remember that this is a global trend and that this issue is not unique to the United States. As digital inventory and the use of 3D printed replacement parts picks up, such a solution will become more common the world over, perhaps one day even being the go-to choice.

The Research & Development Tax Credit

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Taking Off With 3D Printing

The decision to utilize old replacement parts vs new, 3D printed parts will determine how the airline industry handles the uptick in travel demand since COVID-19. The industry should consider how the parts will seamlessly fit in to improve function as well. The 3D printing industry can soar to new heights in meeting this demand.