Hidden at the back of their Rapid+TCT booth, Mosaic Manufacturing displayed an amazing 3D print technology.

Mosaic Manufacturing is best known for their Palette series of 3D print accessories. These devices “read” a stream of GCODE and determine how to change colors during a print job. The machines then literally splice together a multicolor filament to make that happen. It’s an amazing technology, but the company has now branched into far bigger things.

The most visibly bigger thing is of course their factory system, the Mosaic Manufacturing Array. This is essentially a 3D print farm in a box — a very large box — that includes all necessary features to serially make parts for low volume production.

That’s a big step for the company, but it was announced over a year ago. They are still growing sales of the device, but along the way they’ve been working with manufacturers to identify new applications that might be deployed on the Mosaic Manufacturing Array.

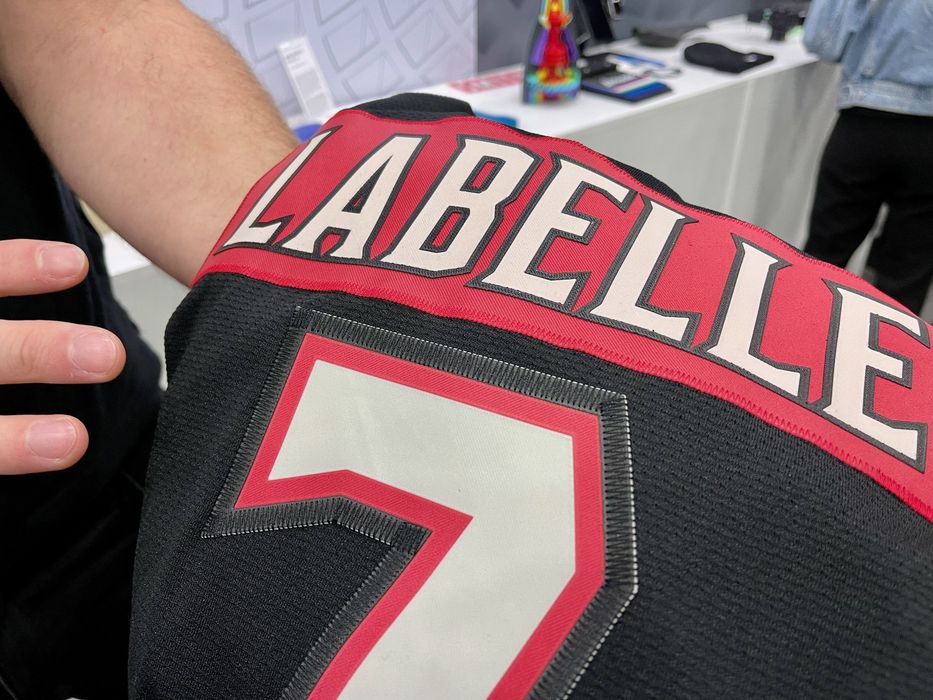

One client working with Mosaic Manufacturing is Toronto-based Athletic Knit, one of the world’s largest producers of team-based uniforms and apparel. The main feature that makes team uniforms different from normal apparel is the presence of logos, names, numbers and other features. This is Athletic Knit’s speciality.

Mosaic Manufacturing realized there was an opportunity here to revolutionize their business and that industry. They undertook an iterative process to develop a method of 3D printing labels, logos and numbers using their equipment, but with newly developed materials.

The result is something they call “E-Twill”, a system for 3D printing on fabric. The system will 3D print directly on various fabrics, but also produce iron-on pieces for later application.

You might correctly point out that 3D printing on fabric is not new. That’s true, it has been experimentally done for several years, most notably by Susana Marques. It was attempted commercially in 2015 by 3D Systems, but that venture, like many by 3D Systems in that era, quietly faded away. More recently, Stratasys announced a system dedicated to fabric 3D printing, the J850 TechStyle.

It would appear that Stratasys has the edge here, but there are some challenges they have to overcome: while the Stratasys full color fabric prints are incredibly realistic, they are quite expensive to produce using PolyJet technology and are not particularly durable. That could not work for Athletic Knit and similar companies.

Instead, Mosaic Manufacturing has developed a fabric 3D printing process that is highly economical and can be built to scale using their array system.

As for durability, they’ve tested E-Twill fabric prints by running them through a washing machine for weeks at a time, with no degradation in color or loosening of attachment. They’ve also managed to find a material chemistry that produce a perfect matte texture.

The prints themselves are incredibly strong, and it’s literally impossible to rip them apart with your hands, as you can see here.

My thought is that Mosaic Manufacturing may have uncovered a powerful application for 3D printing that has largely been ignored by the industry due to costs and other complications. By overcoming those challenges, Mosaic Manufacturing could be on the verge taking over this particular application niche.