Mosaic Manufacturing announced they’re now shipping their latest hardware, the Palette 3 and Palette 3 Pro.

If you’re not familiar with the Palette line of 3D print accessory, you should be. They are devices that can magically transform any desktop FFF 3D printer into a multimaterial device.

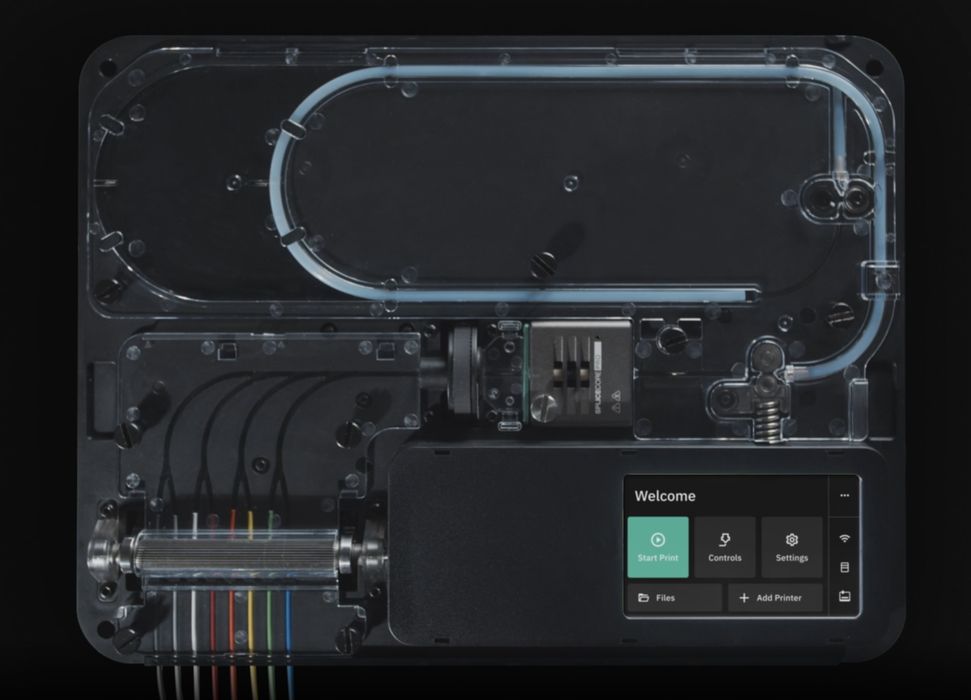

The concept behind the Palette is at first glance perhaps a bit crazy. They sought a way to instantly change the material at the hot end in a way that didn’t involve altering the 3D printer itself. Their idea was to examine the GCODE for a multimaterial 3D print job and identify the positions in the filament stream that would have to change material. Then, they built a machine that would literally cut and splice a custom filament to those specifications — on the fly.

It sounds ridiculous at first, but through effort the company actually made this work, and work very well. The Palette devices accept a number of input material spools that can be spliced together to form an odd-looking Frankenstein filament that heads to the 3D printer.

The hot end on the 3D printer knows nothing, and simply prints what’s pushed into it. The magic is that the materials change as the print job proceeds in just the correct way to achieve the desired outcome.

Typically, the Palette is used to produce multicolor output, although in theory it could be used for different materials, if the temperatures were compatible.

Palette 3

Mosaic Manufacturing has been refining this process for years now, and the latest iteration is the Palette 3, which is now shipping.

The Palette 3 comes in two models, the base unit and the Pro version.

The Palette 3 accepts up to four input filaments, and it includes a new “Splice Core” that’s more reliable and efficient. It is also able to automatically switch from one input to another of the same material, should the first spool run out during a long job. One possible configuration is to have all four inputs as the same material and enable extremely long print jobs.

The Palette 3 is equipped with WiFi, meaning it does not require a long cable from your printer location to your workstation, which might be physically separated.

Mosaic Manufacturing also provides “Canvas” software to not only slice 3D models for use with the Palette, but also can “paint” colors onto the surfaces of uncolored 3D models before printing.

Palette 3 Pro

Meanwhile, the Palette 3 Pro is different — and not only because it comes in a black finish where the Palette 3 is white.

The Pro version’s most differentiating feature is that it accepts twice as many input filaments: eight in total.

That provides not only a wider breadth of colors for a given print job, but also enables extraordinarily long print jobs. Consider the use of 2kg spools: the Palette 3 Pro would place no less than 16kg of material at a 3D printer’s disposal. I have a suspicion the Palette 3 Pro would be an outstanding accessory for belt 3D printers or Quinly-equipped 3D printers, which can run continuously for weeks.

The Pro version also includes a two-year warranty, rather than the single year provided with the base unit.

Finally, the Palette 3 Pro can splice ten percent faster. This might seem to be a minor feature, but consider a very long running job as described above: a ten-day job would take only nine days. The longer the job, the more savings achieved.

Palette 3 Pricing

The two models are priced differently. The base unit is priced at US$599, and the Palette 3 Pro is priced at US$799.

That may be a steep price, considering you can purchase entire 3D printers for less, but think of it this way: what 3D printer can you purchase that includes eight different colors?