A food tech startup hopes to develop a powerful and economical food 3D printer.

Mooji Meats is a Y Combinator graduate startup that is one of the several players in the alt-meat space. This is the technology to produce lifelike food products, but using methods other than traditional farms.

Two approaches have emerged in this space: plant based solutions and alt-meat produced in bioreactors. The plant-based solutions take regular grain crops and through innovative methods transform it into meat-like food products. You may have seen some of these in the grocery store or restaurant: Beyond Meat and Impossible Foods are two of the most well-known brands.

But the alt-meat process is a bit different in that it uses actual animal cells — but not the animal itself — and brews them up in a bioreactor to generate sufficient quantities to make into food products.

Both approaches are valid, but they both suffer from the texture problem: when you assemble the food material into a product it just doesn’t feel like “real meat”. This is why most of the existing players focus on ground meats like hamburger or sausage equivalents: there’s no expectation of texture.

But if you wanted to produce a food product that acts, feels and tastes like a cut of meat, you must introduce a complex texture.

This has been done using 3D printing. One company doing so now, perhaps the only one, is Redefine Meat, who recently opened up sales in Europe. Their system is plant-based and uses a 3D printer to extrude material to match real meat textures.

Baltimore-based Mooji Meats wants to do the same, but they see a key problem in this approach: it’s too expensive.

I’m not surprised at this, because 3D printing of anything is usually more expensive than alternative methods. The cost is usually driven by the need to build objects in a tedious manner: layer by layer or extrusion by extrusion. Those processes are by definition very slow.

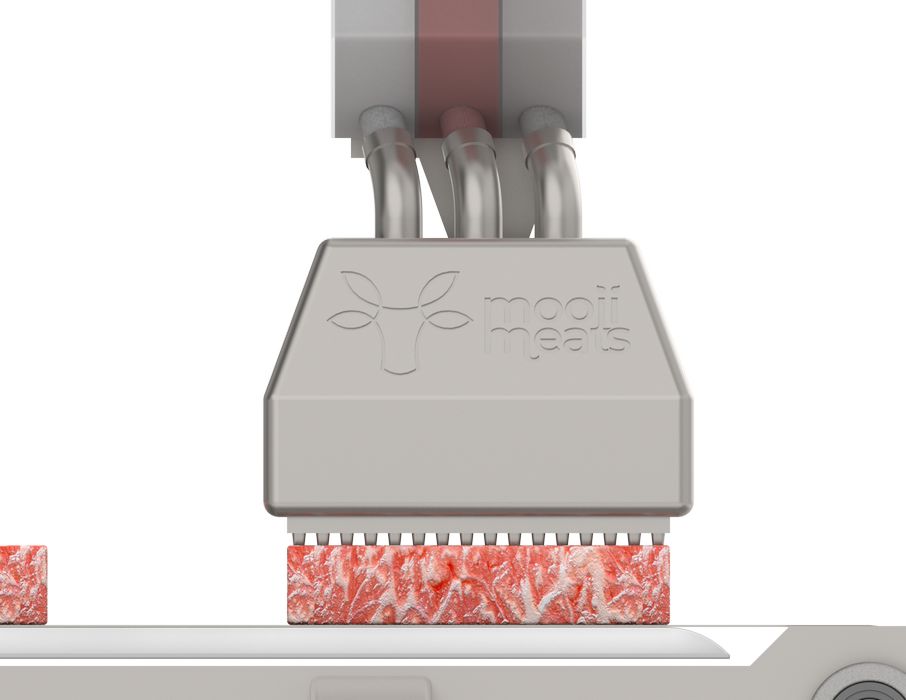

Mooji Meats’ approach is to develop a food 3D printer that uses many nozzles simultaneously. This is quite different from current approaches that typically have a single extrusion nozzle. By using nozzles in parallel there could be very significant speedups in print time, and by extension a lowering of the cost of the meat. That’s because time is money: the cost of the printer can be defrayed over more meat prints during its lifetime.

So far Mooji Meats has raised US$3M in investment funding, which could take them to the stage where they can demonstrate a prototype of the printer concept. If successful they will surely raise a great deal more money, as the market they’re addressing is said to be as large as US$630B. Even a tiny percentage of that market is truly gigantic.

Mooji Meats is still developing the technology, but we’ll be watching their progress.

Via Mooji Meats and TechCrunch