There’s big news from Modix, and I mean “BIG”.

The Israeli company has developed a series of larger-format FFF 3D printers over the years, even naming one of their product lines, “BIG”. Now they’ve revealed a new large-format 3D printer, the Modix Everest, “a printer that stands tall”.

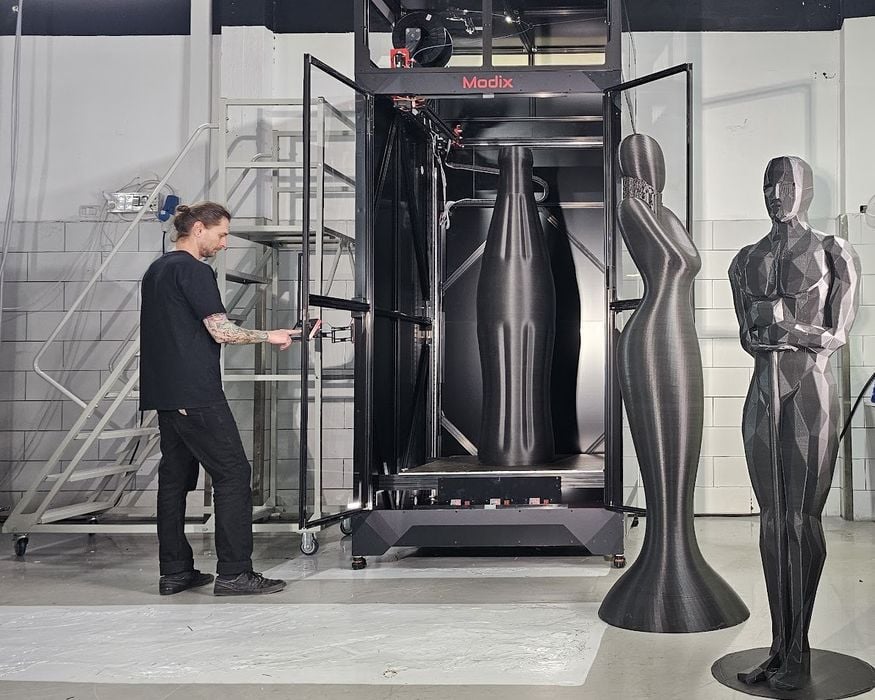

They’re not kidding: the build volume on this FFF device is an incredible 970 x 1030 x 2000 mm. It can print tall objects up to 2m in height, something very few 3D printers can achieve.

The Everest seems to take technology cues from the company’s previous BIG-Meter 3D printer. That machine was able to print within a 1000 x 1000 x 1000 mm build volume. The Everest appears to stretch that in the vertical direction, and retains many of the technology features.

There’s one question that many large-format 3D printers struggle with: print duration. When an object is scaled up the volume of material increases dramatically, and correspondingly the print duration is lengthened, sometimes dramatically so. Early large-format FFF devices sometimes took weeks to complete large jobs.

The first question I wondered about with the Everest was how Modix would tackle the print speed issue, given the incredibly large build volume.

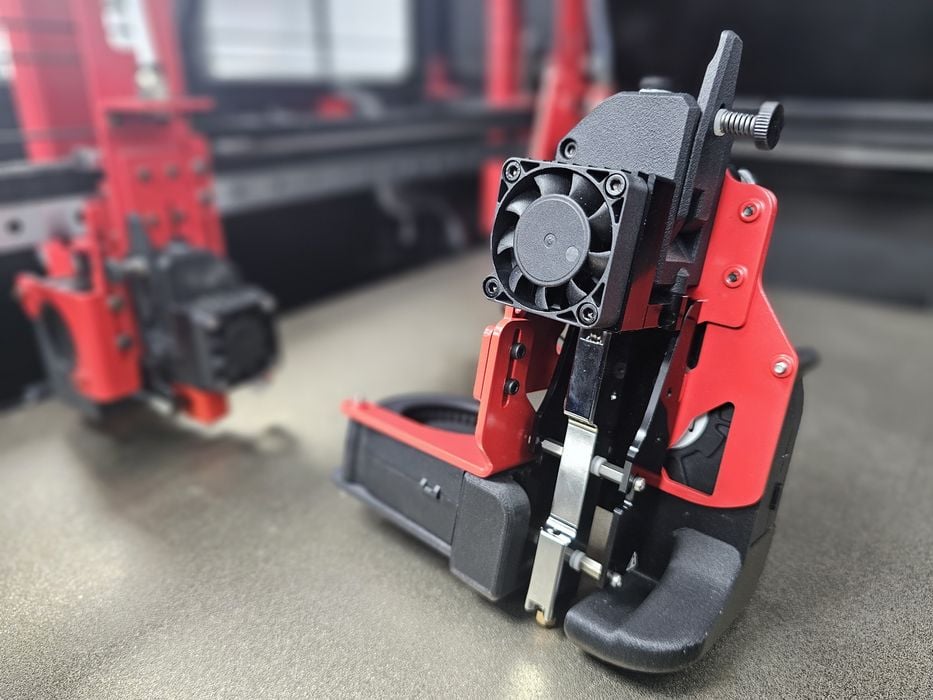

Their answer seems to be a new extruder, the Griffin. It’s a large capacity extruder, capable of delivering an amazing 500g of material per hour. To put that in perspective, that would be a 3D printer consuming 12 x 1kg spools per day.

The stock nozzle diameter on the Griffin is a huge 1.6mm, far larger than the standard 0.4mm nozzle you see on most FFF devices. This allows the Everest to more easily deposit huge amounts of material.

That large nozzle diameter also results in thicker layers that would normally lower the surface quality of prints. However, that doesn’t matter nearly as much on large prints, where the huge size hides the layer lines.

Modix explained that the Griffin is capable of high speeds. It can deposit layers of 1.2m thickness at a print speed of 250mm/s, which is quite impressive.

The result of this extruder and motion system on the Everest dramatically speeds up prints. Modix explained that prints that previously might have taken twelve hours can now be complete in only two hours on the Everest.

Modix has opened pre-orders for the Everest and Griffin extruder, with anticipated deliver some time in August of this year.

We’ve also learned that the company has been developing two more interesting products.

The first is a customized slicing software tool for their equipment. Evidently it’s to be based on PrusaSlicer/Slic3r open source software, but will include advanced IDEX 3D printing features. This is apparently Modix’s first step into the software world.

The second product is to be a filament dryer that is specifically designed for large-format filament spools. This is quite understandable, as machines like the Everest will best run with larger capacity spools to reduce operator intervention. However, most of the filament drying solutions on the market today seem to address 1kg spool sizes. The new filament dryer, when it is announced, could resolve those issues not only for Modix, but anyone using larger capacity spools.

Via Modix