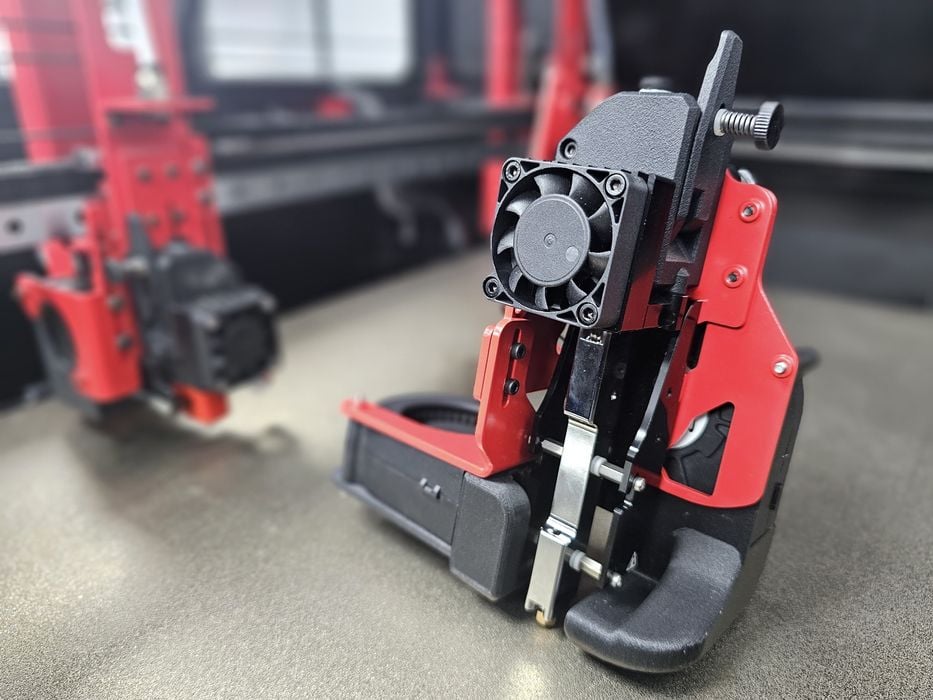

Modix continues its quest to optimize large-format FFF 3D printing with their new toolhead, the Griffin Ultra.

The Griffin Ultra was first announced a few weeks ago as part of the company’s new Modix Everest large-format 3D printer. The Griffin Ultra features a massive 1.6mm nozzle, far larger than typical 0.4mm nozzles, and even larger than the standard 0.6mm nozzle used on most of Modi’s other devices.

The Griffin Ultra is able to extrude a humungous 500g per hour (that’s equal to twelve 1kg spools per day), making print jobs take far less time.

One of the key capabilities of this toolhead is that it is capable of laying down layers as thick as 1.2mm, whereas typical extrusion systems can reach only 0.4mm. This gives the Griffin Ultra a huge 3X speed advantage for layer size alone. Modix calculates the print speed to be 2.6X for solid layers and perimeters. Combining this together implies a total speedup of almost 6X.

The news is that Modix is now offering the ability to upgrade any other non-Everest Modix 3D printers to use the new Griffin Ultra toolhead. That could provide a massive speed advantage for operators of these devices.

Above are examples of the speed advantage. These life-size prints are produced in less than a day, which is quite amazing when compared to most FFF 3D printers.

Modix also provided some before/after comparisons of specific print jobs:

| MODEL | DIMENSIONS (mm) | GRIFFIN 0.6mm | GRIFFIN 1.6mm |

| Bottle | 450 x 450 x 200 | 77 hours | 17 hours |

| Container | 440 x 260 x 290 | 80 hours | 12 hours |

| Bracket | 630 x 180 x 30 | 4.5 hours | 0.8 hours |

You can see that the time saved tends to run between 4-7X, quite significant.

You may be skeptical given the rather large layer sizes from the wide-diameter nozzle on the Griffin Ultra. That’s understandable to someone that prints smaller items.

However, Modix equipment is typically used to produce very large objects, where the coarser layer lines optically disappear due to the larger size. In other words, the coarse surface quality really doesn’t matter for this class of objects.

Modix also announced they’ve made progress on their new slicing system. Based on the popular open source PrusaSlicer, Modix intends on integrating a number of features that are beneficial to large format 3D printing. These features will never appear in PrusaSlicer itself as the tool is focused on desktop-sized 3D printers.

Large format features include:

- A more effective wiping tower – you can control the size (X&Y) of the wipe tower as well as the infill for better wiping of large nozzles

- A more stable wiping tower shape – with a wide trapezoidal base (pyramid)

- Print in IDEX mode with two different nozzle diameters (save soluble filament by using smaller nozzle)

These are interesting developments that should all greatly assist 3D printer operators in producing large-format objects.

Via Modix