MIT has developed a device that can literally produce a fully functional object in one step, with no human intervention.

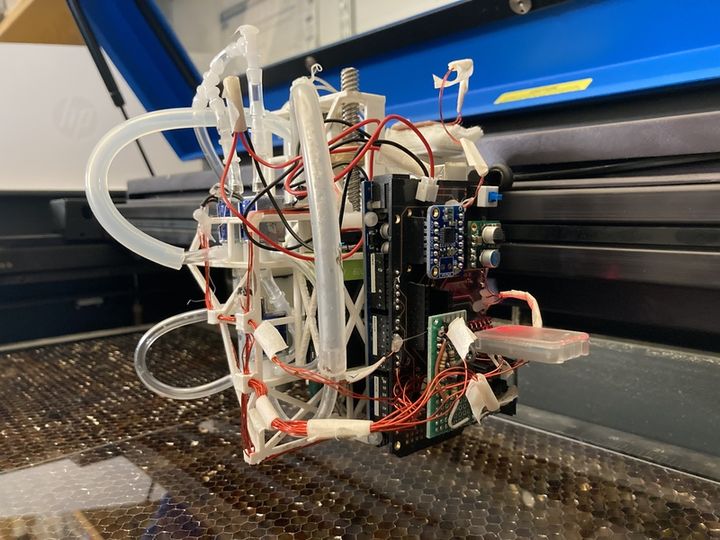

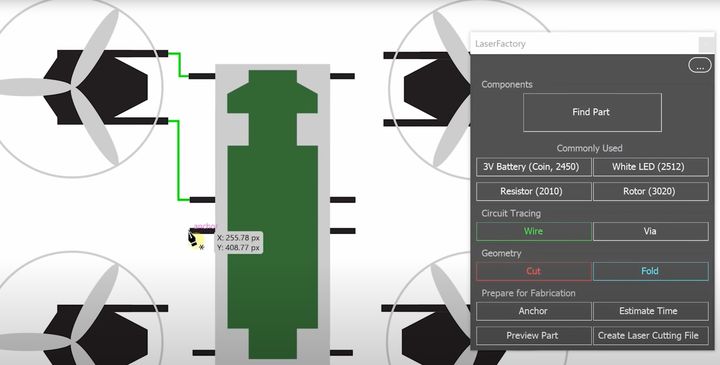

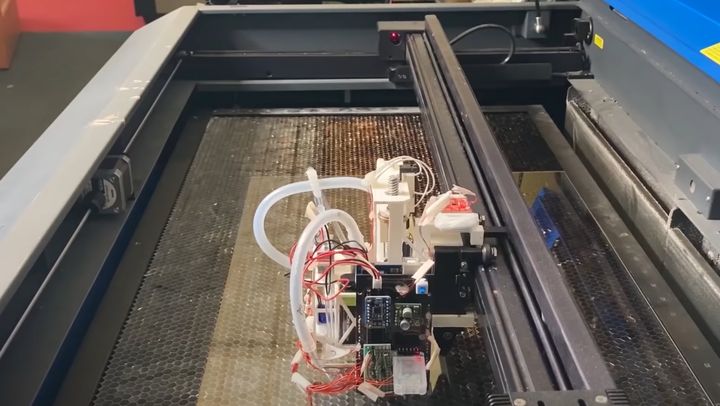

The concept, called “LaserFactory”, is actually an add-on for laser cutters. It uses the existing laser system, but adds the ability to pick-and-place objects, and to extrude conductive silver paste.

MIT LaserFactory

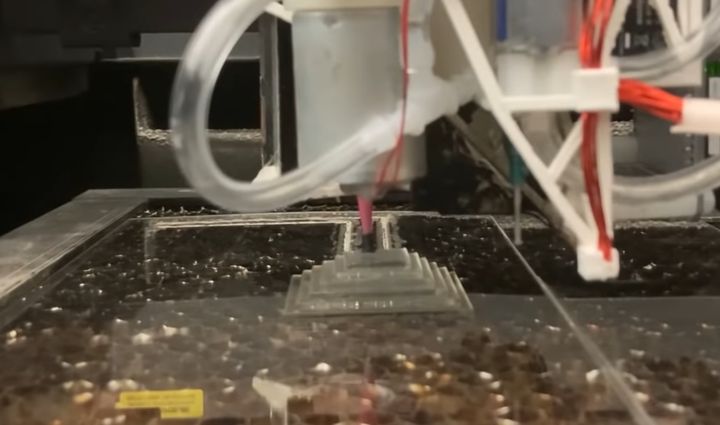

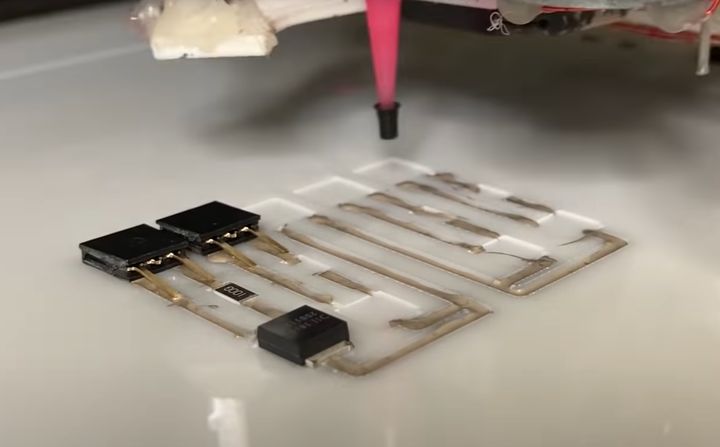

The idea is that the laser cutter can chop out 2D pieces that make up the physical structure, while the silver paste can be used to electrically connect components. The components can be placed automatically, including electronic chips, motors or other pre-made components.

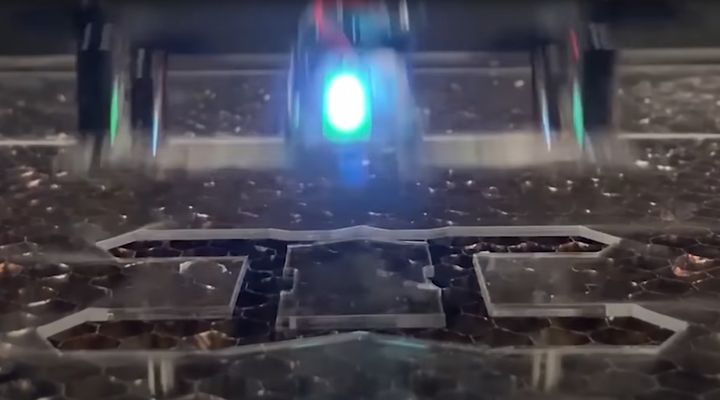

The laser is used to heat-cure the silver paste to transform it into conductive traces. This allows full electric connectivity between placed components, if so desired.

There are some variations in the process beyond what you’d normally expect with a 2D laser cutter. For example, the pick-and-place function could stack laser-cut pieces into 3D designs.

In this video example, MIT researchers show how a simple drone can be produced with the LaserFactory. Note how the drone literally takes off from its cut-out of the larger acrylic sheet on the laser cutter!

There’s two parts to this project: the hardware, including the features mentioned above, and software that allows an operator to design the objects and create suitable toolpaths to achieve the production and assembly.

This is an incredible development, and I have a suspicion those with existing laser cutters might be interested in adding a LaserFactory option to them.

A 3D LaserFactory

However, this is NOT a 3D printing system. It’s really a modification to a 2D laser cutter, impressive though it may be.

But after watching the video several times it seems to me that this concept could relatively easily be adapted for 3D printing instead of laser cutting. Most of the hardware would remain the same, but you’d have to add both a laser and a silver paste extruder to the system.

3D prints can be far more complex than 2D laser cutting, and thus I can well imagine the “3DPrintFactory” would be able to produce more interesting functional objects. The drone, for example, might have more aerodynamic structures.

There would have to be some tuning, however, as the laser would have to deftly cure the silver while not melting surrounding polymers. I’m sure that can be achieved with appropriate timing and laser strength management.

The pick-and-place function would be incredibly useful, as it could automatically insert nuts, PCBs, wiring, metal rods or anything imaginable. This would enable “true” 3D printing of rudimentary functional assemblies in a way that really hasn’t been done yet.

But I can understand why the researchers chose to start with 2D laser technology: it’s a lot simpler and there is already a laser to use. The next 3D steps will be more complex, but also more beneficial.

Via MIT