MIT might have substantially shortened the development cycle for new 3D printer materials.

New materials are constantly being developed for 3D printers due to increasing demands. However, it’s not just the volume of materials that’s increasing. In addition there is also a need for new materials offering specific engineering properties.

When engineers design a part it will have a number of requirements for it to succeed. These could include properties such as heat or cold resistance, impact strength, hardness and more.

Once those requirements are established, the engineer simply looks through material catalogs to find the desired material. In traditional manufacturing this isn’t so much of an issue, because there are countless materials available, and almost always there will be one that closely matches the requirements.

That’s unfortunately not the case in 3D printing, where the count of available materials is still spectacularly low as compared to traditional manufacturing.

It’s not always possible to “shift” traditional materials to 3D printing because they may not have, for example, the proper flow characteristics to operate correctly in an extrusion system.

3D print materials developers thus spend much time developing new materials to fit the market demand. The process of finding a new material involves tweaking the ratios of additives to a base material so that the resulting chemical composition succeeds. This is currently done using trial and error techniques, and, as you might imagine, is quite time consuming.

Test prints must be produced and then undergo the relevant test procedures. Heating, cooling, mechanical testing, etc., must take place, often repeatedly to ensure valid results.

Now that all may change with a new AI system from MIT.

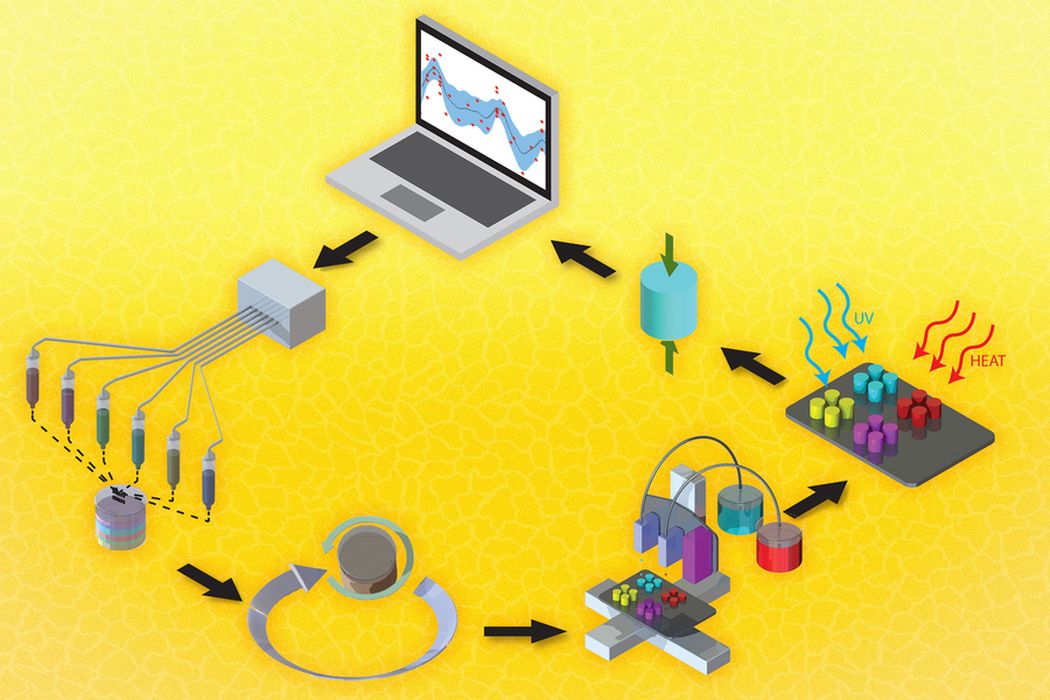

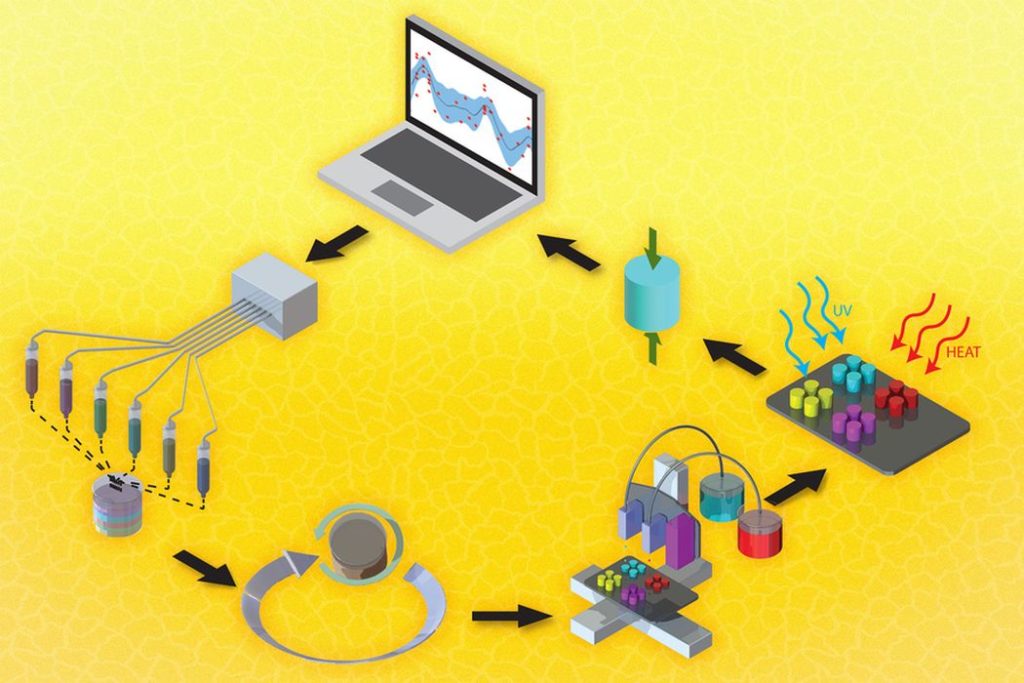

Researchers have developed a process to simulate this sequence of activity using machine learning. MIT explains:

“To cut down on the time it takes to discover these new materials, researchers at MIT have developed a data-driven process that uses machine learning to optimize new 3D printing materials with multiple characteristics, like toughness and compression strength.

By streamlining materials development, the system lowers costs and lessens the environmental impact by reducing the amount of chemical waste. The machine learning algorithm could also spur innovation by suggesting unique chemical formulations that human intuition might miss.”

They say that with current manual techniques it’s possible to evaluate only a couple of potential materials over several days. However, with the new system they can process “hundreds” of possibilities in the same time.

How exactly does this work? MIT explains:

“A material developer selects a few ingredients, inputs details on their chemical compositions into the algorithm, and defines the mechanical properties the new material should have. Then the algorithm increases and decreases the amounts of those components (like turning knobs on an amplifier) and checks how each formula affects the material’s properties, before arriving at the ideal combination.”

Once the projected optimum mix is identified, the materials developer can complete the job preparing the new chemical mix and physically testing the material.

Apparently they have open sourced the algorithm for this process, and it is available here.

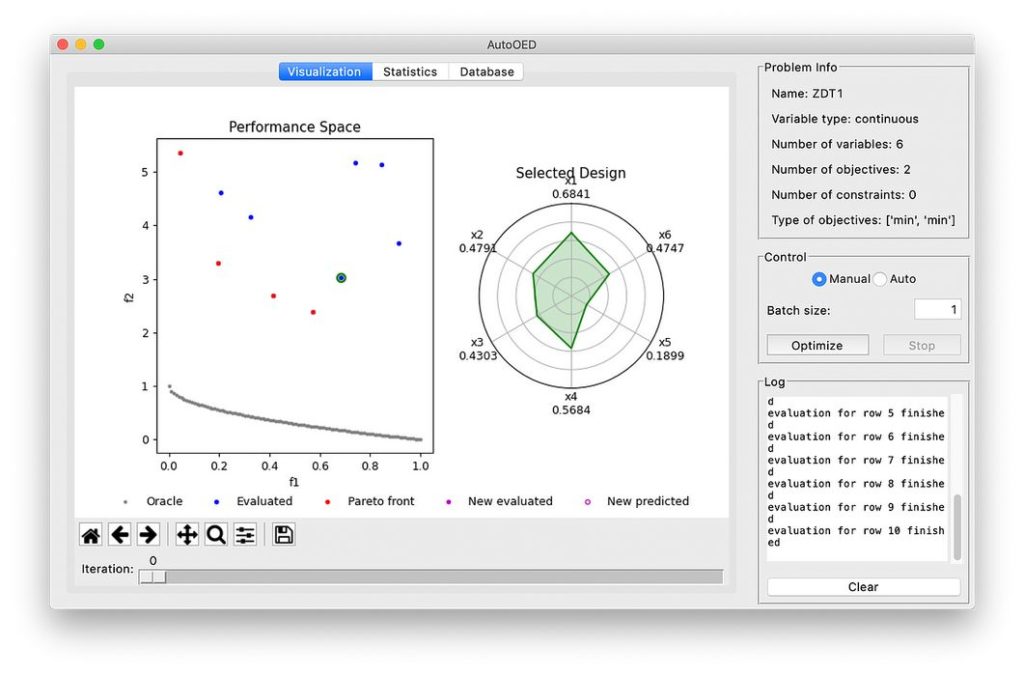

During tests of the new system, the researchers found the results to be not only correct, but offering the operator choices through different trade-offs. This happens due to conflicts between properties that inevitably occur when ingredient ratios change.

They also found the test results to have a much wider range of possibilities than would have been created by previous manual approaches.

It seems this may be the way forward for future materials development in 3D printing.

If you think there are many choices of materials for your equipment today, keep watch for the future.

Via MIT