Minifactory announced a tool for 3D printers I hadn’t seen previously: a Nozzle Alignment Camera.

Nozzle alignment is a critical calibration step required by dual-nozzle 3D printers. This is because the slicing software assumes there is a very specific distance (in all three axes) between the tips of the nozzles, and organizes toolhead movements accordingly.

However, in practice, nozzles are typically not aligned. They may be shifted vertically or in other directions, and this causes gaps or blobs as the nozzle may end up being either too close or too far away from where it should be.

Alignment errors need only be very slightly off in order to produce poor quality results, so it’s imperative to get the calibration correct on dual nozzle 3D printers. Usually the alignment process involves a process of measuring the error and telling the software how much to correct. Often it’s an approximation, but usually good enough for most.

On the other hand, Finland-based Minifactory has long pursued perfection in 3D printing. While they produce excellent industrial high temperature 3D printers, they are also known for their automated quality control system, Aarni. Aarni can provide detailed quality reports for parts produced on Minifactory systems, and should be quite useful during part qualification and subsequent tracking.

In their endless pursuit of print quality they’ve developed a new system to make prints even better. Their latest innovation is a new means of aligning dual nozzles via an optical system.

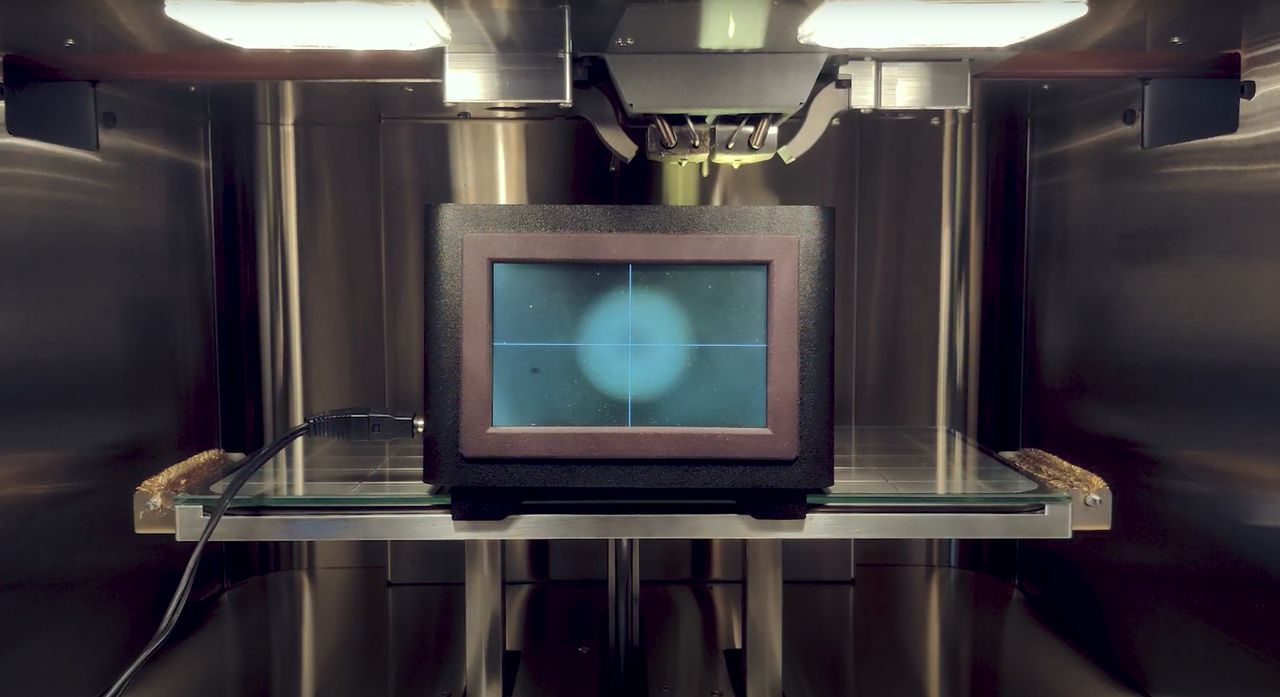

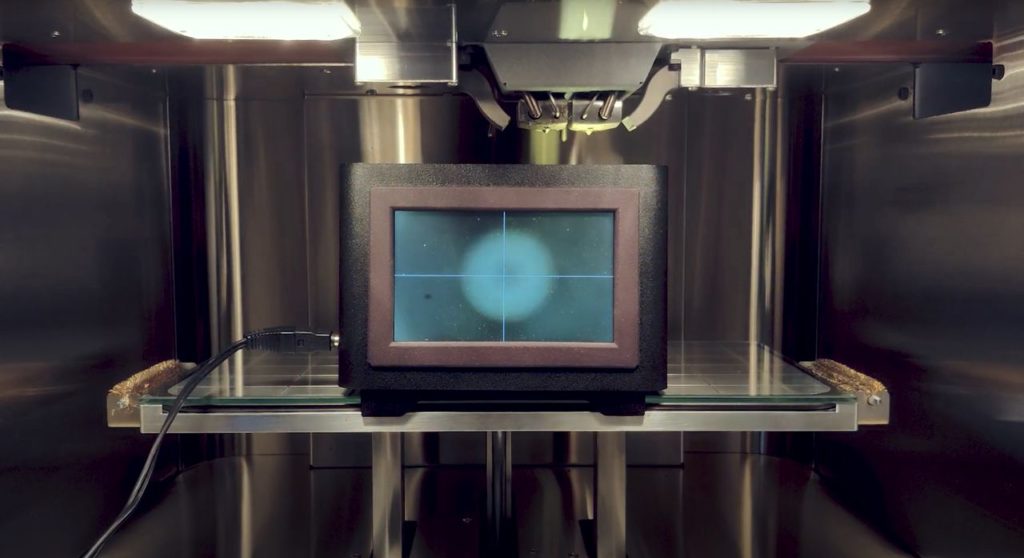

As you can see in the video, a specialized camera is placed on the print bed. The toolhead is moved so that the nozzle is pointing directly at the camera, or rather the camera is looking direct up the filament path through the nozzle.

The lens system on the Nozzle Alignment Camera is designed to show a detailed, close-up view of the nozzle.

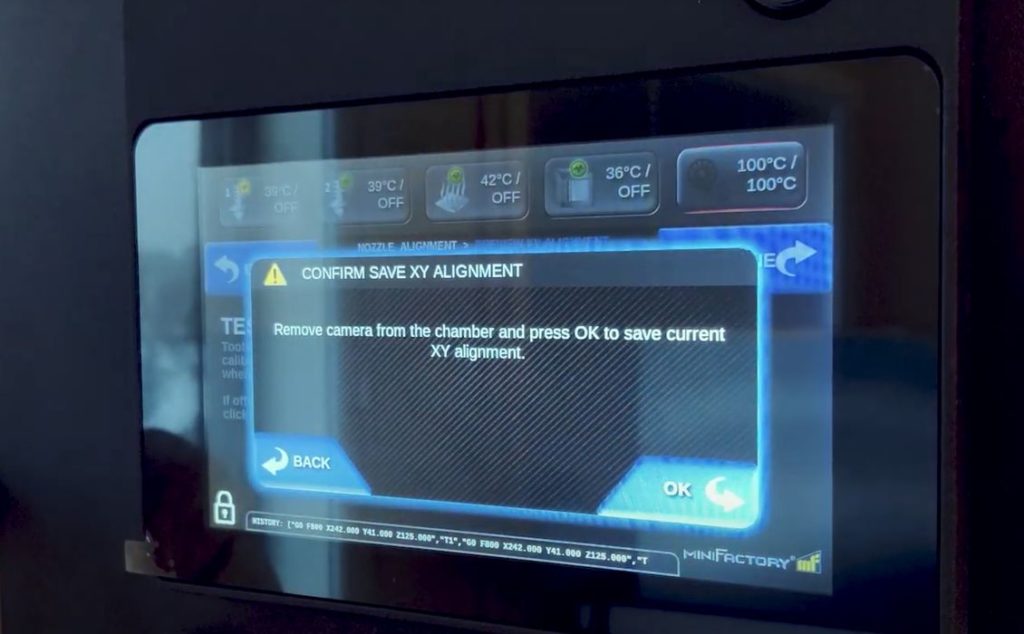

Once the first nozzle’s position is identified, the second nozzle is shifted over the camera lens and when it’s in final position, the difference in position can be precisely calculated. This provides the software with an outstanding calibration for dual nozzle alignment.

This is the first time I’ve heard of such an optical system being used for nozzle alignment, but it seems to be a technique that is effective and precise.

In theory a Nozzle Alignment Camera system could work on any dual-nozzle 3D printer, along with associated software changes. However, at the moment you’ll have to do this only on Minifactory gear.

Via Minifactory