We caught up with Valcun, the makers of an incredible 3D printer that uses aluminum wire.

The startup company launched only a couple of years ago. In 2022 we saw print samples showing they were somehow able to 3D print aluminum in a manner very similar to standard FFF 3D printing: with filament and an extruder.

When I first heard about this approach I was skeptical: when aluminum is heated sufficiently, it melts. I imagined an extruder violently dripping liquid aluminum, forming a puddle rather than a solid usable part.

They insisted they were able to do exactly that, however. It was explained that they have figured out how to very precisely control the thermals so that the aluminum wire is softened “just right”, and rapidly solidifies with suitable cooling.

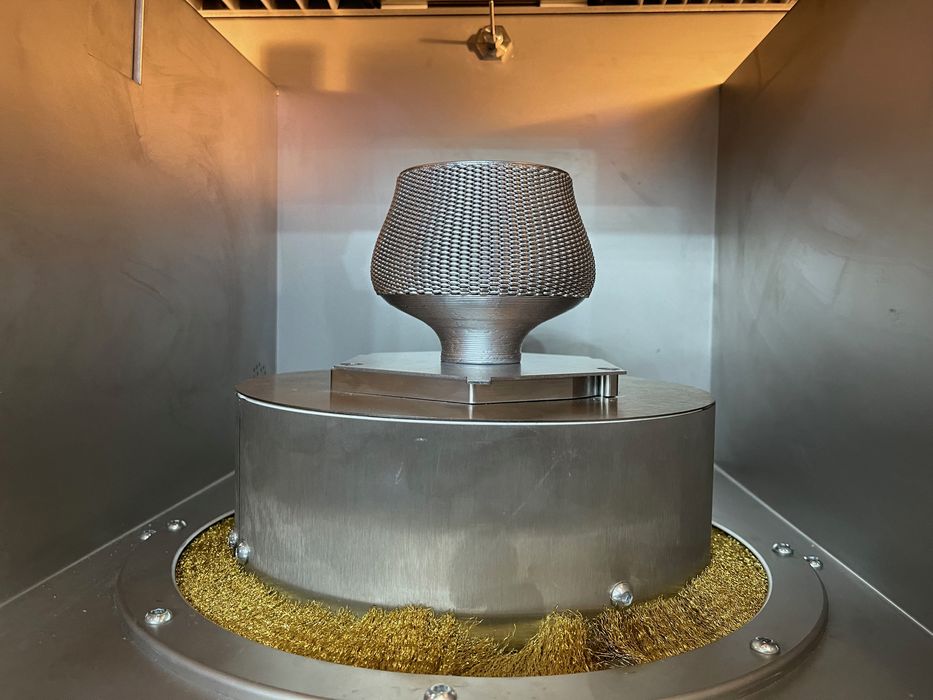

This year at Formnext I was able to see their machine for the first time in person. Indeed, their spools were quite literally aluminum wire, as you can see above.

The machine, called the Minerva, is intended to be properly launched by the end of the year. They’ve partnered with a contract manufacturer to produce the machine, so they’re lining things up for commercialization and scaling. However, they did say they actually sold machines at Formnext to parties attracted to the idea of 3D printing aluminum.

They say they will have capacity to produce around 20 machines per year, and after doing so they will revise the machine design and produce “Gen 2”.

However, at this point they are focusing mostly on firming up the customer market. This is an issue facing any company developing a new style of 3D printer: who is the customer? They’re trying to narrow down the possible applications, and one they’ve seen interest in is the printing of heat exchangers.

Valcun is, for the moment, focusing on universities as their initial market, something many other 3D print manufacturers have done. Valcun told us it’s a bit too early for production use, but I got the impression that would be something for the future.

While Minerva currently prints aluminum, the Valcun process is applicable to other metals. We were told they want to show that this is possible, and could likely be done through their new university partners.

Valcun seems to be in a good state at the moment. We’ve seen significant progress from them over the past two years, and they are positioning for commercialization.

The only question is, which market will benefit most from their metal filament printing technology?

Via Valcun

This article provided no details on the build environment/atmosphere

High vacuum? Very time consuming and high maintenance

Inert gas? Prints run for a long time – if an “open” process, that would mean a lot of spent gas and potential oxygen depletion hazards

Fighting the formation of aluminum oxides is the neverending challenge

We did not provide more details because there aren’t any. Valcun is extremely secretive about their process, and we were quite surprised they even displayed their machine in public.