Mimaki has improved their clear 3D print material.

Full color 3D printing is an amazing technology to witness, but there are only a few companies producing full color 3D printers. One of them is Mimaki.

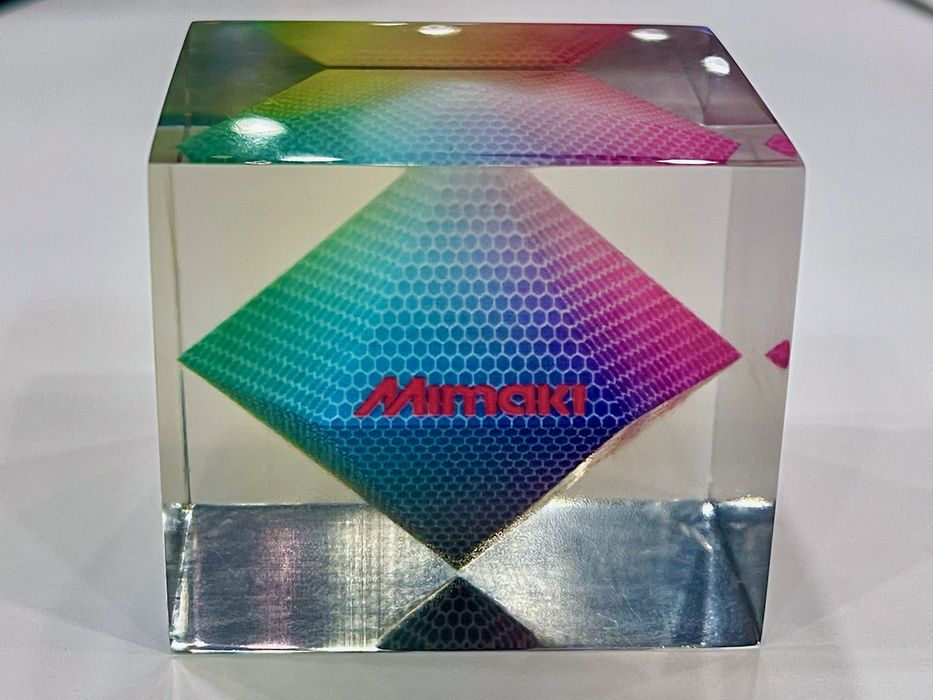

The Japanese company has long been producing high-end industrial 2D printers, but in recent years has entered the 3D print marketplace, specializing in resin equipment capable of reproducing full color objects with incredible detail and realism.

Producing a wide range of colors is a matter of mixing the appropriate ratios of base-color photopolymer resins. In the 2D print world, this is the CMYK concept, where you have cyan, magneta, yellow and black (that’s the “K”) that can be mixed to obtain any desired color.

But in 3D printing it’s a bit different. With 2D printing there is always the pure white paper on which the colors are imprinted. Thus you always have “white” available by default; you don’t even need to print it.

However, with solid objects, there is no equivalent of a background “paper”, so all colors must be produced by the printer. In practice this means a full color 3D printer would have to include not only CYMK, but also clear material. It turns out that there are many instances where clear is required for the 3D model. It’s also possible to mix the clear resin with any color combination to obtain tinted material.

But getting a resin that cures into a truly clear form is a bit tricky. While Mimaki’s current MH-100CL resin is clear, it also exhibits a very slightly yellow tinge. This not only corrupts the clear models, but also makes it challenging to create perfectly colored tinted structures.

The answer is a new resin from Mimaki called MH-110-CL, which reduces the yellow tinge. Mimaki explains:

“The ink is capable of depicting the clear expressions as intended by designers and architects, which is expected to be used in product design for home appliances and cosmetics, as well as in design mock-ups and design verification for industrial products. It is also suitable for use in medical and architectural models requiring visualization to confirm internal structures.”

I asked how they achieved this new formulation, and was told it was a combination of a very slight change in the hardware, plus a “chemistry thing.”

This is good news for Mimaki, which has been marketing the full color products very well against their major competitor, Stratays. I asked what advantage they had over Stratasys, and was told their equipment is about two-thirds to half the cost, with materials costing about half. Currently, the company’s lowest cost machine is the 2207, which runs for about US$40K.

The new resin is now available.

That price point may be attractive, but the big challenge for Mimaki to compete against Stratasys is in marketing. Stratasys is a very big name in the 3D print industry, whereas Mimaki is far less well known.

But that may change in the future.

Via Mimaki