Meltio announced their first client for the hybrid CNC system announced last year.

If you’re not familiar with Meltio, it is a joint venture between Las Vegas-based Additec and Spanish Grupo Sicnova. Grupo Sicnova is a manufacturer and reseller of 3D printers and is quite active in the European market.

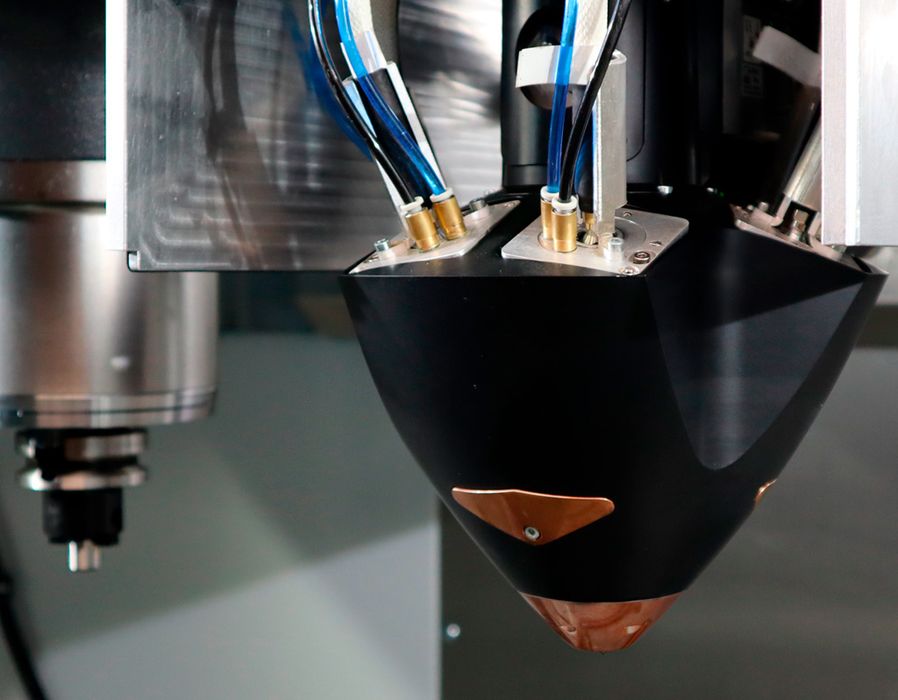

We first encountered Additec in 2019, when they displayed a unique metal deposition print head that could use both powder and wire input materials. The device uses high power lasers to instantly melt either material as it appears in the path. At the time it was mainly a powerful print head installed in a small delta machine and really required attachment to a large, professional motion system to enable additive manufacturing.

One of the big advantages of the system is that it can use common welding wire as input material, which provide not only very low cost, but also a wide selection of material types.

The direct deposition 3D printing process is also significantly more safe than powder-based approaches, because there are no airborne toxic or explosive particles to deal with. This dramatically lowers the cost of operation using this metal 3D printing process.

In February 2020 the two companies announced a partnership to form Meltio to do just that.

It took them several months to organize the technical approach, and later in 2020 they announced the availability of the hybrid CNC toolhead product, which they call the “Meltio Engine”.

The Meltio Engine is an attachment for an industrial CNC machine that can perform additive manufacturing of metal. The CNC provides the motion system, while Meltio provides the additive toolhead. Theoretically, such a system could not only 3D print a metal object, but the standard CNC tooling could smooth out the surfaces and refine holes to produce end-use parts.

Meltio announced that Sivó, a Spanish industrial machine shop has become the first official integrator of the Meltio Engine for the Spain and Portugal regions.

This partnership is two-fold. Meltio explains:

“Sivó is planning on fully enjoying the benefits of Meltio’s hybrid manufacturing solution. On the one hand, they are going to use the machine to improve their glass mold repair process. On the other hand, as part of Sicnova’s sales ecosystem, they are going to be the very first official integrators of the Meltio Engine for machine tools in Spain and Portugal. They are looking to install Meltio’s unique hybrid solution to those willing to upgrade their manufacturing processes.”

Sivó installed the Meltio Engine into one of their Haas UMC-1000SS CNC machines, and the integration process took less than a week to do. The experience from this install will no doubt greatly help when integrating the Meltio Engine into other customers in the region.

This is an important development because it provides a less expensive path for current metal CNC operators into additive processes. By far the majority of metal workshops do not use additive processes, but as time passes it will become increasingly clear to them that they should consider additive options.

However, traditional metal 3D printing has largely been out of financial reach for most of these operations. With the ability to simply modify a machine already on the workshop floor with the Meltio Engine, we might find several pioneering metal workshops looking for a way to leapfrog their competitors by quickly gaining additive capability.

Via Meltio