SPONSORED CONTENT

I had a long chat with Ángel Llavero, CEO of Meltio about their unique metal 3D printing process.

Meltio is a joint venture between US-based Additec and Sicnova, a Spanish reseller of 3D printing gear. The company is leveraging an unusual metal printhead technology from Additec in a variety of deployable printing configurations, including a robotic large-scale system, hybrid CNC milling options, and of course a standalone 3D printer.

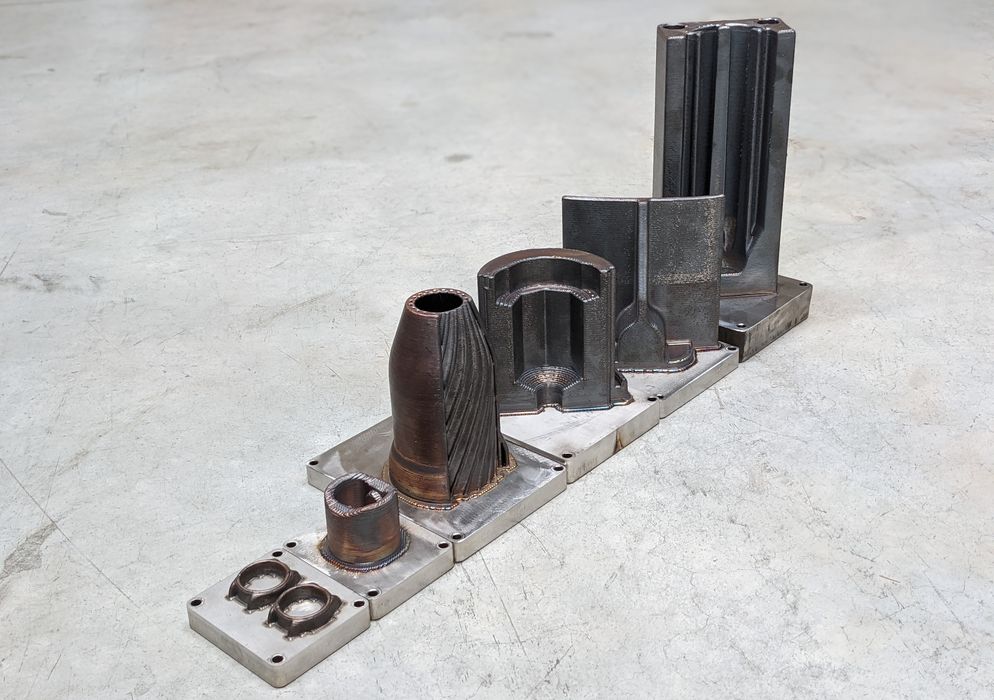

What’s so special about their metal 3D printing process? It’s quite different from the more typical powder bed laser systems, and instead uses a special printhead that can extrude multiple metal materials that is instantly melted by lasers. As the printhead moves around a build volume it can deposit metal precisely in any geometry.

While the printhead from Additec is capable of printing with either metal wire or powder inputs, Meltio is now mostly developing wire applications as they have identified clear benefits for industry when in this mode.

Meltio has increased its focus on the wire mode because it provides a number of advantages sought by their customers. The most important advantage is that the use of wire is far safer and much simpler than handling metal powder in PBF or powder DED systems that can be both toxic and explosive if exposed to oxygen.

The most interesting technical feature is that Meltio’s printhead can handle two wires during a print job. This means it is possible to print metal parts with more than one metal, without cross-contamination.

Meltio’s extraordinary dual wire capability also allows for an increase in the printed part’s performance by cladding with higher performance materials or adding new functionality to parts. In addition, dual wire enables the use of low cost sacrificial material for supports or non-critical build areas. The wire switching process does not require hardware or feedstock change, it is also automatic, quick (in 5 seconds), and clean. The wires retract in a solid state into the print head.

Unlike most 3D printer manufacturers that focus on the relatively small prototyping and professional markets, Meltio has targeted the metal manufacturing sector, specifically machine shops, and the company has many features that should be attractive to that very large market.

There are three pillars that Meltio leverages for the machine shop market: simplicity, flexibility and experience.

The simplicity is inherent in the design of the technology: because it does not use powder, the entire operational lifecycle is vastly simpler and less expensive than almost all other metal 3D printing options. This is certainly very attractive to small and medium-sized metal operations where there can be perceived complexity and financial barriers to getting into metal 3D printing. Meltio’s system avoids much of that and should enable a far easier entry into additive operations.

The flexibility seems to be a philosophy throughout the company. For example, when I asked how they handle print profiles, they explained they can provide them, but also work directly with clients to co-develop parameters, particularly on large projects. They say their role is to support modifications by the clients, and can handle any approach.

Similarly, they provide complete flexibility in robotic or CNC integration, which is required for any deployment of their products on robotic or CNC systems. Meltio is agnostic for the brand and model of robot or CNC, as well as the software to drive the equipment. This, I believe, is a critical capability because there will be potential clients that already have and use their own robotic and CNC systems and won’t want to buy or learn anything new just for additive capability. In other words, this flexibility widens their market.

Finally, there’s customer experience. Llavero spent considerable time explaining the steps Meltio takes to ensure customers succeed and have a good experience. He said:

”All companies have a good experience. When they first buy our machines they get reduced production time, reduced materials used, and reduced cost – all without contamination or complications.

We want to be the best metal machine for manufacturing, and the most important thing is quality.

We don’t want to sell machines; we want them to buy machines.”

That last point is very interesting, pull versus push. There are few 3D printer manufacturers taking that approach, which I see as a way to ensure trust with clients and prospects.

I think Meltio is on to something here because there are indeed a vast number of smaller metal operations that have effectively been shut out of additive capabilities due to the extreme cost of PBF systems, as well as the incredible complexity involved. It’s common to see AM shops staffed with squads of engineers carefully tuning print super-expensive print jobs, but that’s not something smaller operations would want to get into.

The much more simple approach offered by Meltio could be quite attractive. For example, the material type can be swapped on Meltio equipment in less than ten minutes, whereas with PBF systems you often cannot change the material – EVER! I’ve seen some companies literally buy second machines to use a second metal material. PBF approaches must be scary for many metal operations.

The Meltio technology could enable metal operations that are not in the high-priced aerospace, automotive or healthcare sectors to use additive manufacturing in a practical and cost-effective manner. For many such operations this technology could enable them to take on smaller jobs much more readily with competitive pricing for their clients.

Llavero said:

“Companies are seeing in Meltio what they wanted 25 years ago from metal AM systems, it’s a new opportunity for manufacturers. These customers always wanted to use 3D printing, but it has barriers: speed, cost, space, hardware, etc. In the last six months we’ve seen strong interest, and they love the tech. Thanks to our volume strategy and the choice of wire as feedstock our system are much more competitive for everyday metal parts.”

I have a feeling that Meltio could have a winning strategy here, and one that addresses the part of the metal market that has been mostly ignored by the rest of the 3D printing industry: machine shops. Llavero believes the market for Meltio technology is similar in size to the CNC market.

USA is Meltio’s first commercial priority in 2022. We will be in several cities and exhibiting at several conferences, including AMUG, RAPID/TCT and IMTS.“ There is also a new office in Florida, with a product showroom.

The company is indeed setting up for expansion. With their hybrid CNC offering, they already have arrangements with CNC resellers and robot integrators, who would have relationships with most, if not all of the metal manufacturers. Llavero said their channel ecosystem approach extends beyond customers and also includes integrators and resellers.

Meltio has also partnered with quite a number of large US universities. These have been provided with Meltio technology for research purposes, so it’s possible many graduates may have experience with Meltio products by the time they leave university.

Llavero said Meltio now has around 70 staff, but they currently have about 20 open positions. Apparently they intend to have around 110 staff by the end of the year, if any readers are interested in joining their team.

I’m very interested to see Meltio’s progress in the machine shop market that has been long-underserved by the industry.

Via Meltio