MELD announced a new hybrid device to produce large metal parts.

If you’re not familiar with MELD, they offer a unique 3D printing process based on friction welding. Basically, two metals are rubbed against each other at high speeds, which generates friction and heat. Eventually the heat is sufficient to soften the metal and it “melds” into the structure being built. You can see where the company gets their name.

The system works by rotating a cylinder of metal and pressing it against the target. This produces solid metal structures rapidly, but with coarse resolution. They are able to process a wide variety of metals, including some that are not normally weldable.

There are a number of advantages to the process, as we discovered during an interview with the company’s CEO a couple of years ago.

A very important advantage is that this solid state process doesn’t involve any powder. Metal powder is used in several other metal 3D printing processes, but it is problematic. Metal powder can be toxic, explosive and can become airborne. It also is easily corrupted by exposure to atmospheric oxygen, leading to considerable challenges in handling the powder.

Not so with MELD’s solid state approach, as there is no powder, just metal.

But the disadvantage is that the parts produced have not-so-great resolutions due to the nature of the process. This is ok for many types of parts, particularly those with larger dimensions that allow the surface irregularities to fade away.

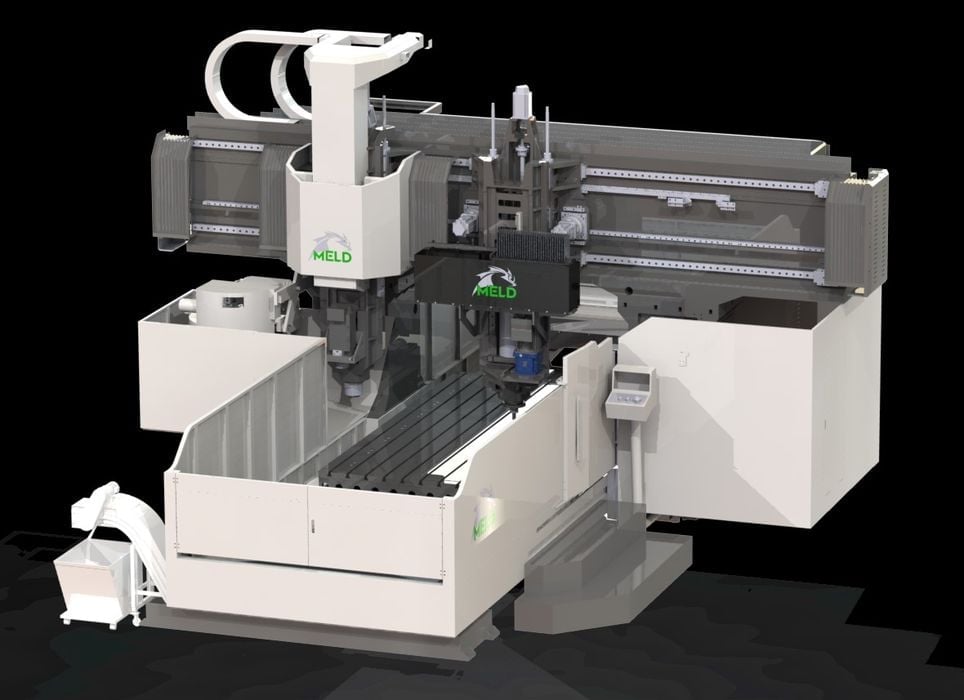

However, it seems that MELD has overcome this issue with their new hybrid device, the 3PO.

This unit includes a standard MELD friction welding toolhead, but also a metal CNC milling toolhead. The idea is that as the metal layers are deposited, they can be milled to the desired surface quality.

The 3PO has quite a large build volume, 4000 x 2700 x 1000 mm, making it possible to 3D print finished metal objects of enormous size. MELD said the milling head can travel at up to 200m per second, meaning the smoothing process is quite rapid.

The milling tool comes standard with three axes of movement, but it’s possible to substitute an optional five axis mechanism to enable more complex surface processing.

The 3PO is definitely not for everyone, but it does address an important market niche: huge custom metal parts. Normally these would take many months to produce using conventional approaches, but the 3PO should be able to do so in only days.

A MELD spokesperson suggested that they see applications in factory equipment, such as silicon production, or anywhere you’d normally see “big forging”.

This includes military applications, where the company has apparently been doing significant work in recent years. They are participating in a congressionally-funded program where attempt will be made to 3D print types of certain military vehicles.

This has generated quite a bit of interest in MELD and their unique process. We were told the company doubled in size last year, and they expect that to continue.

Via MELD