Stratasys announced an interesting arrangement with CollPlant Biotechnologies that could lead into a major line of business for the company.

They are to jointly develop a series of bio-fabrication solutions for the human body. Stratasys wrote:

“Stratasys and CollPlant Biotechnologies today announced a joint development and commercialization agreement to collaborate on the development of a solution to bio-fabrication human tissues and organs using Stratasys’ P3 technology-based bioprinter and CollPlant’s rh-Collagen-based bioinks.”

Their first project is to develop a way to scale up CollPlant’s regenerative breast implant concept. The idea is to replace the current synthetic silicone implantation method with a more biocompatible solution. CollPlant has tested a solution on a small scale:

“In January 2023, CollPlant announced that it successfully completed a large-animal study for its 3D bioprinted regenerative breast implants. The preclinical study demonstrated progressive stages of tissue regeneration after three months, as highlighted by the formation of maturing connective tissue and neovascular networks within the implants, with no adverse events reported. Based on these positive results, CollPlant is planning to initiate a follow-up, large-animal study in the second half of 2023 using commercial-size implants to support subsequent human studies and future product commercialization.”

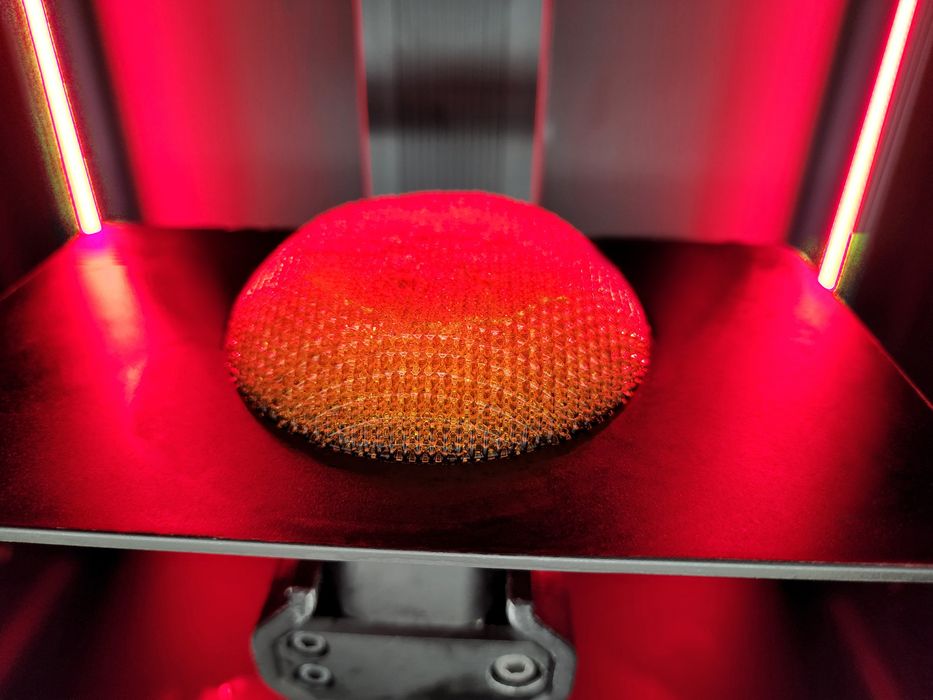

You may recall Stratasys’ P3 printing technology from their prior acquisition of Origin, who developed the P3 printing process. The P3 process uses photopolymer resins combined that uses sensor feedback to precisely control printing. This enables them to achieve incredibly complex and high quality 3D prints.

P3 uses photopolymer resin, which is one of the most versatile 3D printing materials. By combining the base photopolymer with other substances, many different materials can be produced, including ceramics, composites, flexible, and even metal.

And biocompatible materials.

That’s where the CollPlant Biotechnologies angle comes in. CollPlant is an independent company based in Israel that is developing a variety of biotech materials. They explain:

“CollPlant is a regenerative and aesthetic medicine company developing innovative technologies and products for tissue regeneration and organ manufacturing.”

But to do so you’ll need a 3D printer, and that seems to be how Stratasys fits in here.

It seems that Stratasys will be creating a new bioprinter based on P3 tech, but designed to be used with CollPlant bioresins. Stratasys explains:

“The new bioprinter, based on Stratasys’ precise P3™ 3D printing technology in combination with CollPlant’s flagship bioinks, will enable the production of CollPlant’s state of the art breast implants, which are being designed to regenerate an individual’s natural breast tissue without eliciting immune response, providing a potentially revolutionary alternative for both aesthetic and reconstructive procedures.”

The market size for breast implants is apparently US$2.6B annually, which is a large number. But let’s think about this a bit: that’s ONE bioapplication that could be done with this 3D printer. How many other bioprocedures could there be that could also be made with this device and similar materials?

I think you may now realize that Stratasys could be venturing into a vast future market for bioprinted implants, tissue and, possibly, eventually, organs.

The partnership with CollPlant seems to be quite strategic for Stratasys. However, CollPlant had previously made an arrangement with 3D Systems. In 2020, they announced an agreement to cooperate on developing biosolutions. Then, in 2021, 3D Systems announced they were working with CollPlant to develop a “3D bioprinted regenerative soft tissue matrix for use in breast reconstruction procedures in combination with an implant.”

At that time 3D Systems, like Stratasys, did not have a 3D bioprinter.

This is quite curious: CollPlant making deals with two different 3D printer manufacturers to produce what sounds to be the same solution. There are only these possibilities:

- 3D Systems was unable to produce an effective solution and CollPlant has moved on to try Stratasys instead

- CollPlant is developing the product with two different companies to see which one is better

- CollPlant actually has two similar but different solutions at play that do not overlap

- Stratasys somehow offered CollPlant a better deal and they decided to move forward with Stratasys

I’m interested to see how this develops, both in the corporate space and biologically.

Via Stratasys